Injection device

An injection cylinder and injection molding technology, applied in the field of injection devices, can solve the problems of increased number of components, large-scale, complicated structure of injection devices, etc., and achieve the effect of high injection speed and high injection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Hereinafter, the injection device according to the embodiment of the present invention will be described.

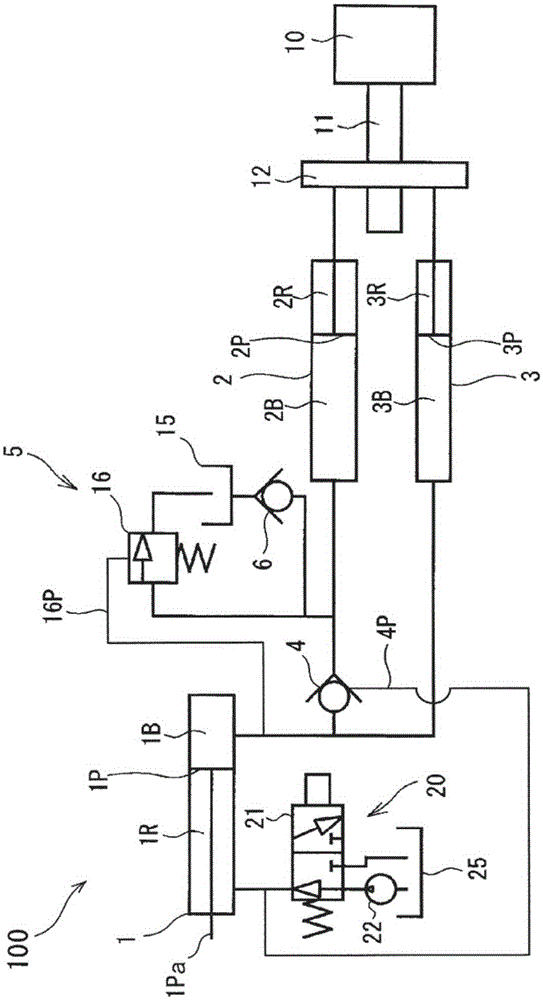

[0010] A die casting machine as an injection device is a device that injects and fills a molten metal material (for example, aluminum) as a molding material into a cavity formed by a fixed mold and a movable mold constituting a mold. The molding material injected into the mold is taken out after solidification, thereby becoming a desired molded product. Reference figure 1 , The die casting machine 100 includes an injection cylinder 1. The injection cylinder 1 is a component that drives an injection plunger that extrudes a metal material supplied into an injection sleeve communicating with a mold cavity into the mold cavity. The injection plunger is connected to the tip of the piston rod 1Pa of the piston 1P of the injection cylinder 1. The injection cylinder 1 is connected with a booster cylinder 2 as a first cylinder and a booster cylinder 3 as a second cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com