Production method for buckwheat bowl holder

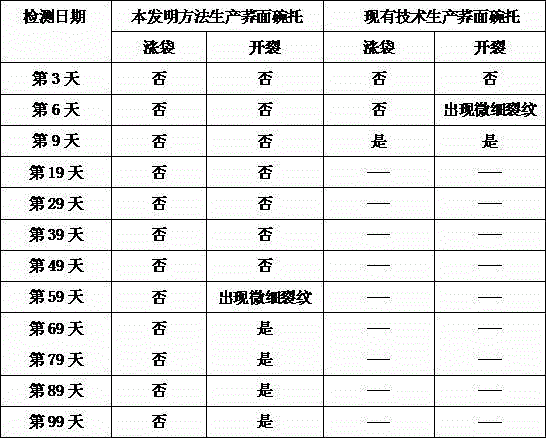

A production method, the buckwheat noodle bowl holder technology, is applied in the production field where ripening and sterilization are completed at one time, and can solve the problems of inability to form large-scale production, short shelf life, secondary pollution, etc., achieve labor saving, simple method, and avoid pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take 5kg of buckwheat noodles and add 4kg of drinking water, put it in the noodle mixer and stir evenly, let it stand for 30 minutes, then add 15kg of drinking water while stirring, stir it into a paste, and then fill it in food-grade high-temperature resistant plastic bags. Bag 100g, remove the residual air in the bag and seal it, then place the sealed buckwheat paste bag in a boiling water bath to mature for 35 minutes, shape it while it is hot, cool it naturally, and store it at 10-15°C.

Embodiment 2

[0029] Take 5kg of buckwheat noodles and add 6kg of drinking water, put it in the noodle mixer and stir evenly, let it stand for 40 minutes, then add 10kg of drinking water while stirring, stir it into a paste, and then fill it in food-grade high-temperature resistant plastic bags. 150g bag, remove the residual air in the bag and seal it, then put the sealed buckwheat paste bag in a steam box to steam and mature for 25 minutes, shape it while it is hot, cool it naturally, and store it at 10-15°C.

Embodiment 3

[0031] Take 5kg of buckwheat noodles and add 5kg of drinking water, put them in the noodle mixer and stir evenly, let stand for 35 minutes, then add 12kg of drinking water while stirring, stir into a paste, and then fill them in food-grade high-temperature resistant plastic bags. Bag 200g, remove the residual air in the bag and seal it, then place the sealed bag of buckwheat paste in a pressure cooker to maintain a pressure of 0.1 Mpa, ripen for 12 minutes, shape it while it is hot, cool it naturally, and store it at 10-15°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com