Preparation method and winding storage method of medical adhesive tape

A tape and sticker technology, applied in bandages, bandages, adhesives, etc., can solve the problems of short shelf life and loss of activity, and achieve the effect of extending shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

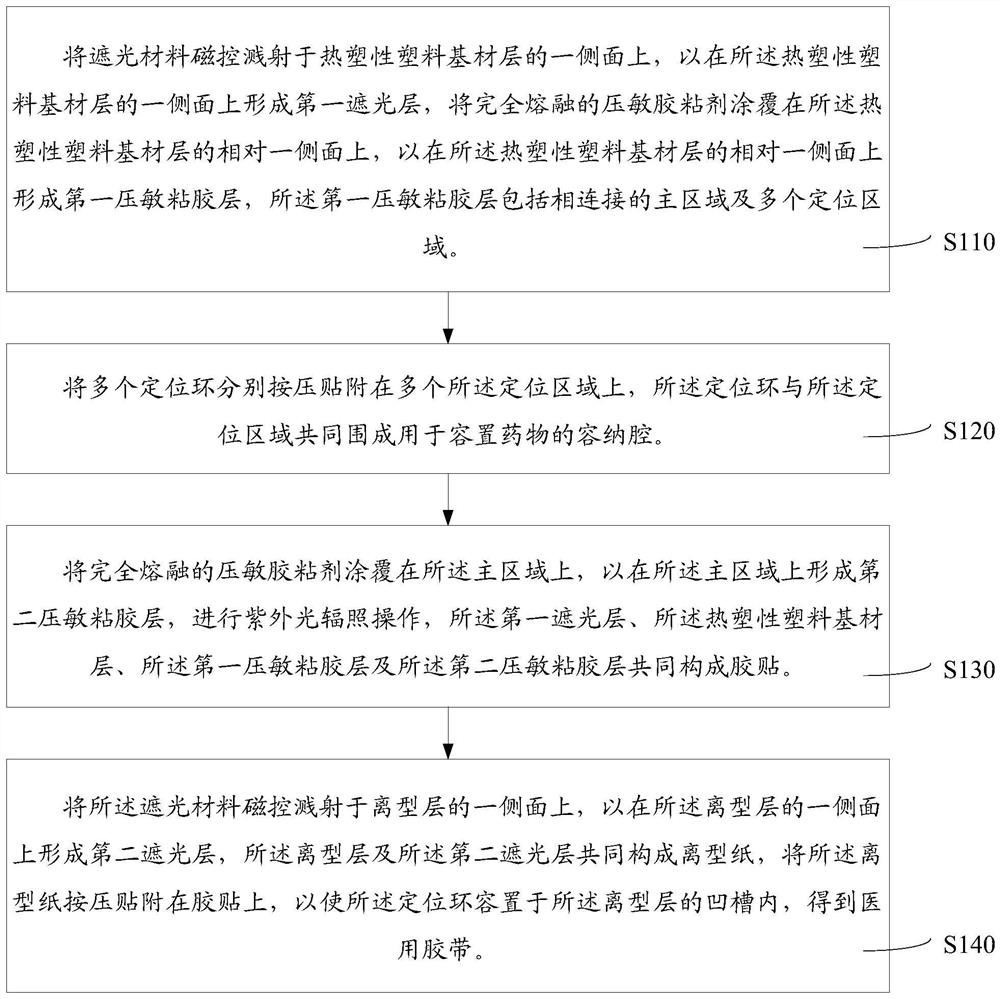

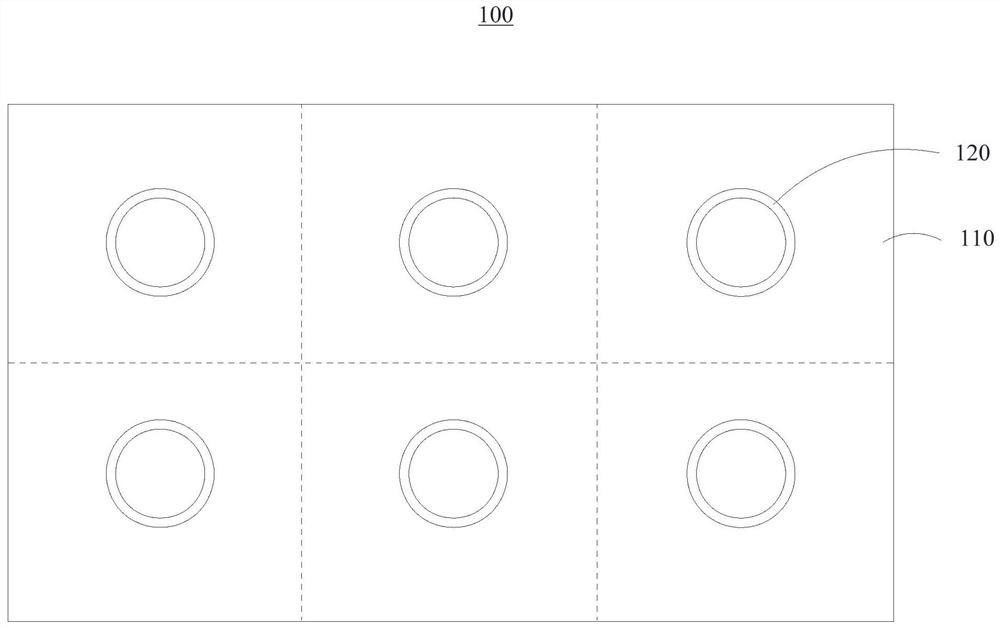

[0032] For an implementation, see figure 1 , a preparation method of medical tape, comprising the following steps:

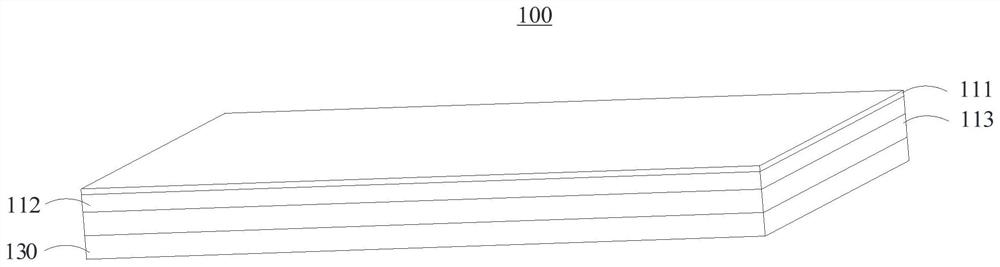

[0033] S110, magnetron sputtering a light-shielding material on one side of the thermoplastic substrate layer to form a first light-shielding layer on one side of the thermoplastic substrate layer, and coating the completely melted pressure-sensitive adhesive on the one side of the thermoplastic substrate layer. on opposite sides of the thermoplastic substrate layer to form a first pressure-sensitive adhesive layer on the opposite side of the thermoplastic substrate layer, the first pressure-sensitive adhesive layer comprising connected main regions and multiple targeting areas.

[0034] S120. Press and attach a plurality of positioning rings to the plurality of positioning areas respectively, and the positioning rings and the positioning areas jointly enclose an accommodation chamber for accommodating the medicine.

[0035] S130, coating the completely melted...

Embodiment approach

[0057] In one embodiment, the polyurethane block copolymer composition is polyurethane thermoplastic elastomer.

[0058] In one embodiment, the styrene-based thermoplastic elastomer is at least one of SIS, SBS, SEBS and SEPS. For example, the styrenic thermoplastic elastomer is a common mixture of SIS, SBS, SEBS and SEPS. For example, the styrene-based thermoplastic elastomer is SIS, SBS, SEBS or SEPS.

[0059] In one embodiment, the tackifying resin is at least one of polyisobutylene, rosin pentaerythritol resin, petroleum resin, terpene resin and rosin resin. For example, the tackifying resin is a common mixture of polyisobutylene, rosin pentaerythritol resin, petroleum resin, terpene resin and rosin resin. For example, the tackifying resin is polyisobutylene, rosin pentaerythritol resin, petroleum resin, terpene resin or rosin resin.

[0060] In one embodiment, the plasticizer is at least one of naphthenic oil, liquid paraffin and white oil. For example, the plasticizer...

Embodiment 1A

[0087] Under vacuum conditions, 100 kg of polyether diol DL-2000 and 40 kg of 4,4-dicyclohexylmethane diisocyanate were added to 100 kg of ethyl acetate, and stirred evenly to obtain a first blend.

[0088] Control the temperature at 60° C., add 1 kg of dibutyltin dilaurate to the first blend, and stir evenly to obtain a second blend.

[0089] The temperature was controlled at 70° C., 20 kg of trimethylolmethane and 1 kg of dibutyltin dilaurate were sequentially added to the second blend, and stirred evenly to obtain a third blend.

[0090] The temperature was controlled at 140° C., 5 kg of amino resin was added into the third blend solution, stirred evenly, and a crosslinking reaction was carried out for 60 s to obtain the polyurethane block copolymer composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com