A method and a detection device for detecting the integrity of the desalination layer of a composite reverse osmosis membrane

A technology of reverse osmosis membrane and reverse osmosis membrane components, which is applied in the field of reverse osmosis membrane integrity detection, and can solve the problems of no detection device and method, few evaluation methods of reverse osmosis membrane, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

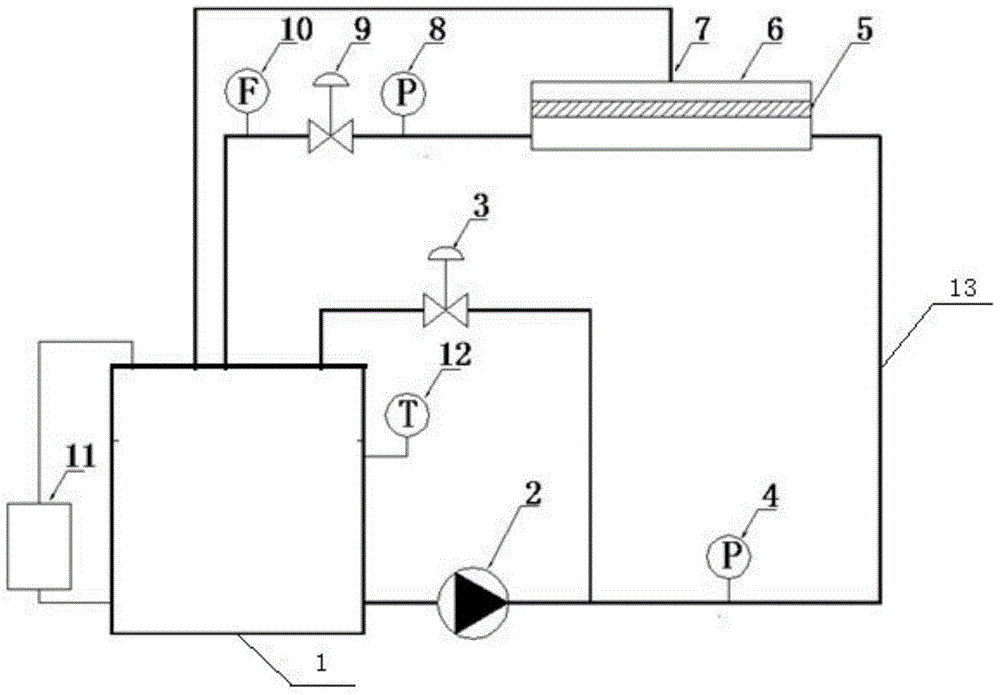

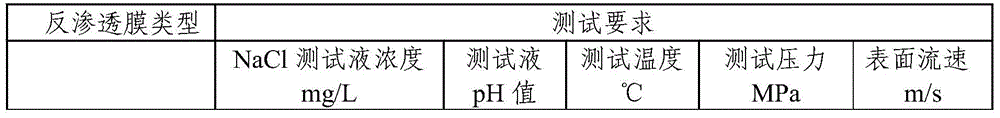

[0028] Such as figure 1 As shown, a method for detecting the integrity of the desalination layer of the composite reverse osmosis membrane comprises the following steps:

[0029] (1) Preparation of test solution: Take water and sodium chloride to prepare a concentration of 245-33000mg / l, then add rhodamine B to it, and use a stirring speed of 350r / min to stir and mix evenly, and control rhodamine B After the concentration of Rhodamine B in the solution is 200ppm, the test solution is obtained, and it is placed in the test solution tank 1, and the pH value is adjusted to 7.45-7.55 for use;

[0030] (2) Membrane installation: the membrane 5 to be tested is installed in the evaluation tank 6, so that the desalination layer of the membrane faces the water inlet of the evaluation tank 6, and is ready for use;

[0031] (3) Pressurized dyeing: turn on the booster pump 2, adjust the stop valve 3 so that the test pressure is 0.39-5.55MPa, and control the temperature to 24.5-25.5°C, ma...

Embodiment 2

[0042] Such as figure 1 As shown, a method for detecting the integrity of the desalination layer of the composite reverse osmosis membrane comprises the following steps:

[0043] (1) Preparation of test solution: Take water and sodium chloride to prepare a concentration of 245-33000mg / l, then add rhodamine B to it, and use a stirring speed of 400r / min to stir and mix evenly, and control rhodamine B Add-on amount, after making the concentration of rhodamine B in solution be 210ppm, obtain test solution, and it is placed in test solution tank 1, adjust pH value to be 7.45-7.55, stand-by;

[0044] (2) Membrane installation: the membrane 5 to be tested is installed in the evaluation tank 6, so that the desalination layer of the membrane faces the water inlet of the evaluation tank 6, and is ready for use;

[0045](3) Pressurized dyeing: Turn on the booster pump 2, adjust the stop valve 3 so that the test pressure is 0.39-5.55MPa, and control the temperature to 24.5-25.5°C, mainta...

Embodiment 3

[0055] Such as figure 1 As shown, a method for detecting the integrity of the desalination layer of the composite reverse osmosis membrane comprises the following steps:

[0056] (1) Preparation of test solution: Take water and sodium chloride to prepare a concentration of 245-33000mg / l, then add rhodamine B to it, and use a stirring speed of 300r / min to stir and mix evenly, and control rhodamine B After the concentration of Rhodamine B in the solution is 190ppm, the test solution is obtained, and it is placed in the test solution tank 1, and the pH value is adjusted to 7.45-7.55 for use;

[0057] (2) Membrane installation: the membrane 5 to be tested is installed in the evaluation tank 6, so that the desalination layer of the membrane faces the water inlet of the evaluation tank 6, and is ready for use;

[0058] (3) Pressure dyeing: Turn on the booster pump 2, adjust the stop valve 3 so that the test pressure is 0.39-5.55MPa, and control the temperature to 24.5-25.5°C, maint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com