Titanium placer mineral processing and tailing fast reclamation method

A technology for titanium placer and tailings, which is applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems that the economy cannot meet production needs, it is difficult to form large-scale mining, and the safety hazards of tailings ponds. The effect of reducing tailings pond capacity, solving transportation cost problems and reducing reclamation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

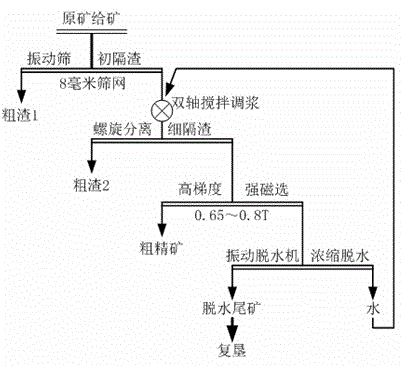

[0018] (1) TiO 2 Titanium sand ore with a content of 8.1% is screened through a vibrating screen to remove solid minerals larger than 8 mm to obtain the residue;

[0019] (2) Mix the residue of step (1) with water through a twin-shaft mixer for slurry adjustment to obtain a slurry with a concentration of 28%;

[0020] (3) The ore slurry obtained in step (2) is finely screened by a spiral groove separator to remove ores larger than 1.5 mm;

[0021] (4) The finely screened ore pulp in step (3) is subjected to strong magnetic desliming at a magnetic field strength of 0.65T to obtain tailings pulp and TiO 2 Coarse titanium concentrate with content >28%;

[0022] (5) Concentrating and dehydrating the tailings slurry obtained in step (4) with a vibration dehydrator to obtain dehydrated tailings with a moisture content of 12%;

[0023] (6) The dewatered tailings obtained in step (5) are tiled for mine reclamation, wherein the tile thickness is 1 meter. The economical wood chestnu...

Embodiment 2

[0025] (1) TiO 2 Titanium sand ore with a content of 8.5% is screened by a vibrating screen to remove solid minerals larger than 8 mm to obtain the residue, which is used for the wall masonry of stepped reclamation;

[0026] (2) Mix the residue of step (1) with water through a twin-shaft mixer for slurry adjustment to obtain a slurry with a concentration of 29.3%;

[0027] (3) The ore slurry obtained in step (2) is finely screened by a spiral groove separator to remove ores larger than 1.5 mm;

[0028] (4) The finely screened ore pulp in step (3) is subjected to strong magnetic desliming at a magnetic field strength of 0.8T to obtain tailings pulp and TiO 2 The crude titanium concentrate with a content of 28.2%, the crude titanium concentrate is sent to the beneficiation process for beneficiation;

[0029] (5) Concentrate and dehydrate the tailings slurry obtained in step (4) with a vibration dehydrator to obtain dehydrated tailings with a moisture content of 15%, and return...

Embodiment 3

[0032] (1) The titanium placer is screened through a vibrating sieve to remove solid minerals larger than 8 mm to obtain the residue, and the solid minerals are used for the wall masonry of stepped reclamation;

[0033] (2) Mix the residue of step (1) with water through a twin-shaft mixer for slurry adjustment to obtain a slurry with a concentration of 35%;

[0034] (3) The ore slurry obtained in step (2) is finely screened by a spiral groove separator to remove ores larger than 1.5 mm;

[0035] (4) The finely sieved pulp in step (3) is subjected to strong magnetic desliming at a magnetic field strength of 0.75T to obtain tailings pulp and TiO 2 Coarse titanium concentrate with a content of >28%, the crude titanium concentrate is sent to the beneficiation process for beneficiation;

[0036] (5) Concentrate and dehydrate the tailings slurry obtained in step (4) with a vibrating dehydrator to obtain dehydrated tailings with a moisture content of 10%, and return the dehydrated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com