Thin-wall welded coil and method for producing the same

A production method and welding plate technology, which are applied to thin-walled welded coils and their production fields, can solve the problems of increasing transportation difficulty and cost, affecting the quality of welded straight pipes, and easy bumping of welded straight pipes, so as to solve the problems of processing design and transportation. cost, improve the utilization rate of welded pipes, and reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

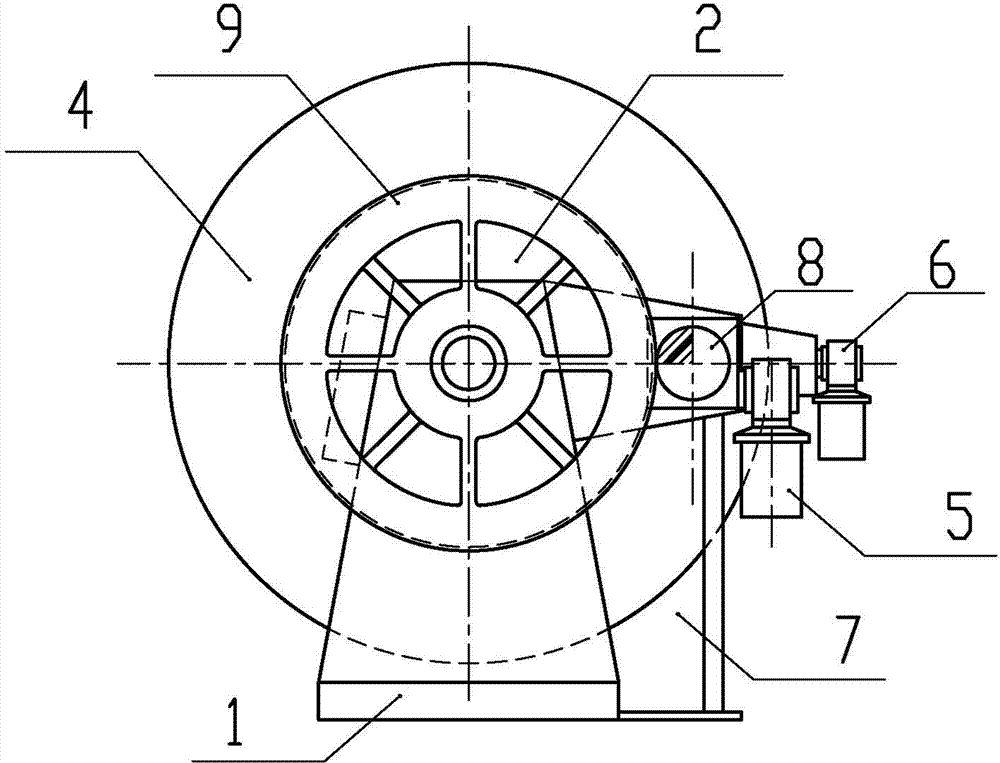

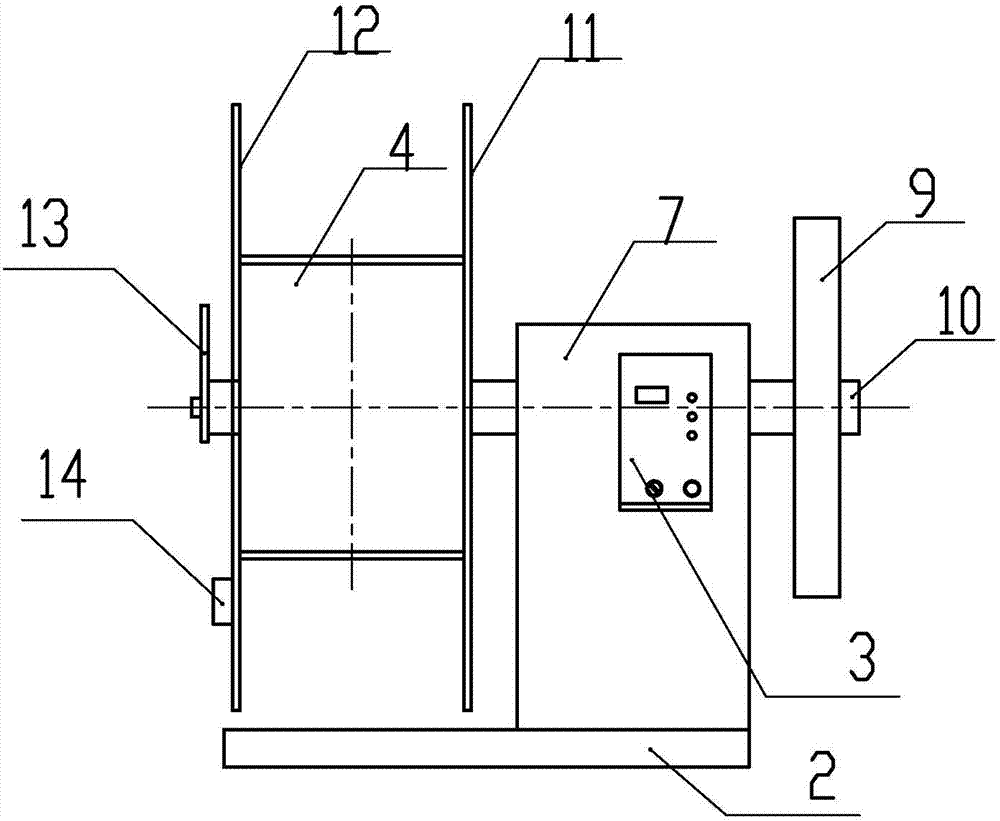

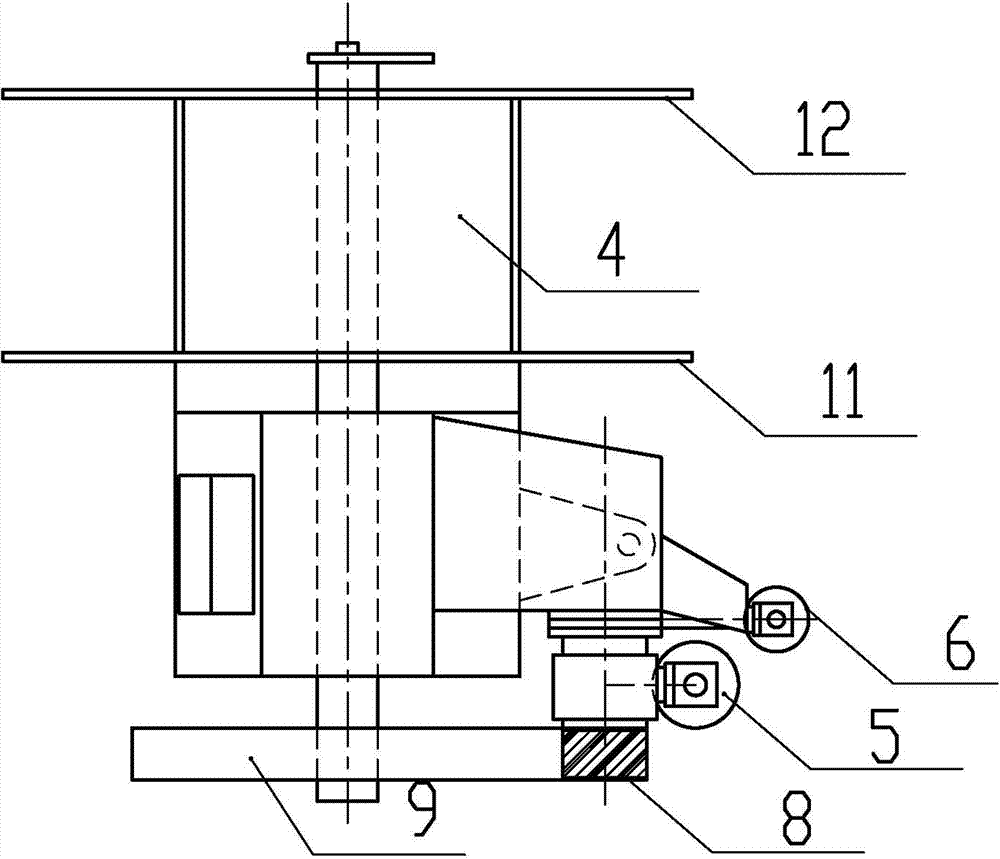

[0027] Depend on figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As can be seen, a kind of production method of thin-walled welded coiled pipe, it comprises the following steps:

[0028] (1) Material selection: select industrial pure titanium strips, stainless steel strips or nickel-based alloy strips as raw materials;

[0029] ⑵Pipe making: industrial pure titanium strip or stainless steel strip or nickel is processed by the pipe making unit including uncoiling mechanism, forming mechanism, welding mechanism, on-line heat treatment mechanism, sizing mechanism, eddy current flaw detection mechanism, on-line coding mechanism and cutting mechanism The base alloy strip is uncoiled by the uncoiling mechanism, rolled by the forming mechanism, welded by the welding mechanism, online annealed by the on-line heat treatment mechanism, sizing by the sizing mechanism, tested by the eddy current flaw detection mechanism, and sprayed by the on-line coding mechanism...

Embodiment 2

[0053] The adjustment mechanism includes a cylinder installed on the shaft sleeve 15, and the piston rod of the cylinder is connected with the arc disc 2. When adjustment is required, the inner diameter of the winding drum 4 is adjusted through the extension and retraction of the piston rod.

[0054] In this embodiment, stainless steel strips are selected as raw materials, and the stainless steel strips are uncoiled by a pipe making unit including an uncoiling mechanism, a forming mechanism, a welding mechanism, an online heat treatment mechanism, a sizing mechanism, an eddy current flaw detection mechanism, an online coding mechanism, and a cutting mechanism. Mechanism for uncoiling, forming mechanism for roll forming, welding mechanism for welding, online heat treatment mechanism for online annealing, sizing mechanism for sizing, eddy current flaw detection mechanism for testing, and online coding mechanism to prepare welded pipes with a wall-to-diameter ratio of 3%. The dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com