A shear-resistant and salt-resistant fracturing fluid thickener

A technology of thickening agent and fracturing fluid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor shear resistance and salt resistance, and achieve strong antibacterial ability, viscosity increasing and thickening performance Good, the effect of improving the effect of production increase transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This implementation provides a synthetic and optimized formula of a shear-resistant and salt-resistant fracturing fluid thickener:

[0029] The thickener is made of raw material components acrylamide, acryl glycinamide, N,N'-methylenebisacrylamide, ammonium persulfate, tetramethylethylenediamine, and deionized water. Wherein, the mass of acrylamide and acryloylglycylamide both account for 1.5% of the total mass of all raw materials. The mass of N,N'-methylenebisacrylamide, ammonium persulfate and tetramethylethylenediamine accounted for 0.5% of the total mass of the two monomers of acrylamide and acryloylglycinamide.

[0030] Preparation method: Add deionized water, acrylamide, and acryl glycinamide in turn to the reactor, stir for 10 minutes, then add N,N'-methylenebisacrylamide and ammonium persulfate, stir and dissolve for 5 minutes, and pour into the reactor Introduce nitrogen, stop nitrogen after 20 minutes and add tetramethylethylenediamine, stir for 5 minutes, r...

Embodiment 2

[0034] This implementation provides a synthetic and optimized formula of a shear-resistant and salt-resistant fracturing fluid thickener:

[0035] The thickener is made of raw material components acrylamide, acryl glycinamide, N,N'-methylenebisacrylamide, ammonium persulfate, tetramethylethylenediamine, and deionized water. Among them, the mass of acrylamide and acryloyl glycinamide accounted for 1.5% and 1.55% of the total mass of all raw materials respectively. The mass of N,N'-methylenebisacrylamide, ammonium persulfate and tetramethylethylenediamine accounted for 0.5% of the total mass of the two monomers of acrylamide and acryloylglycinamide.

[0036] The preparation method is the same as in Example 1.

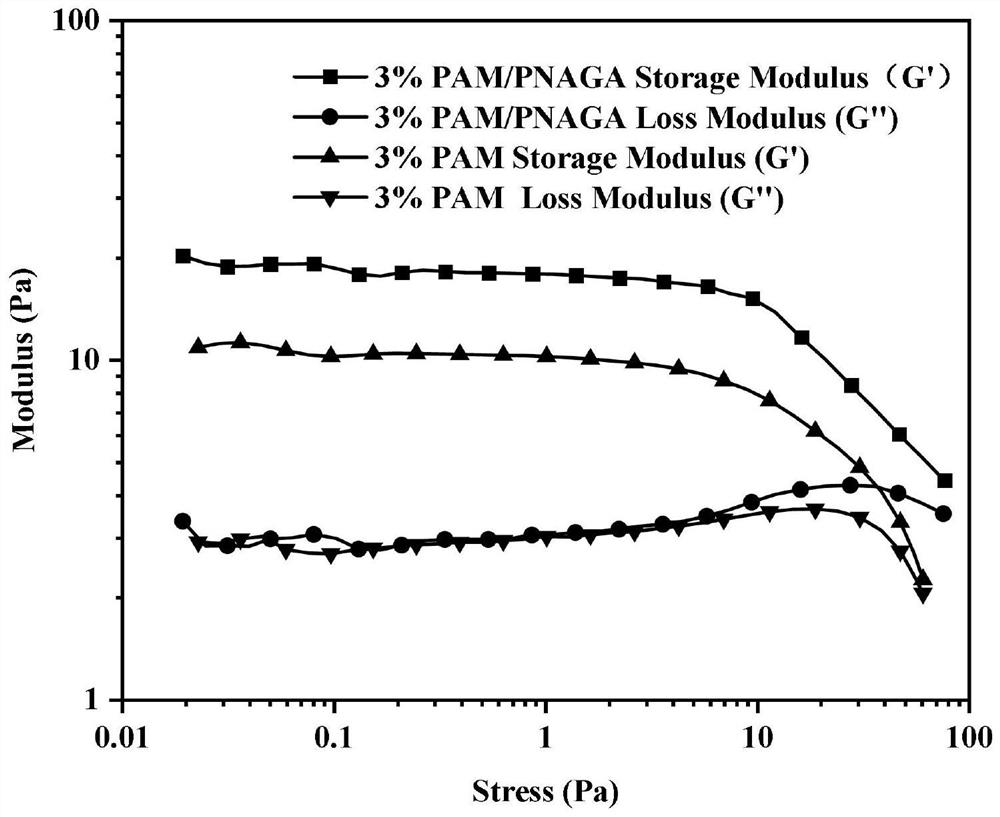

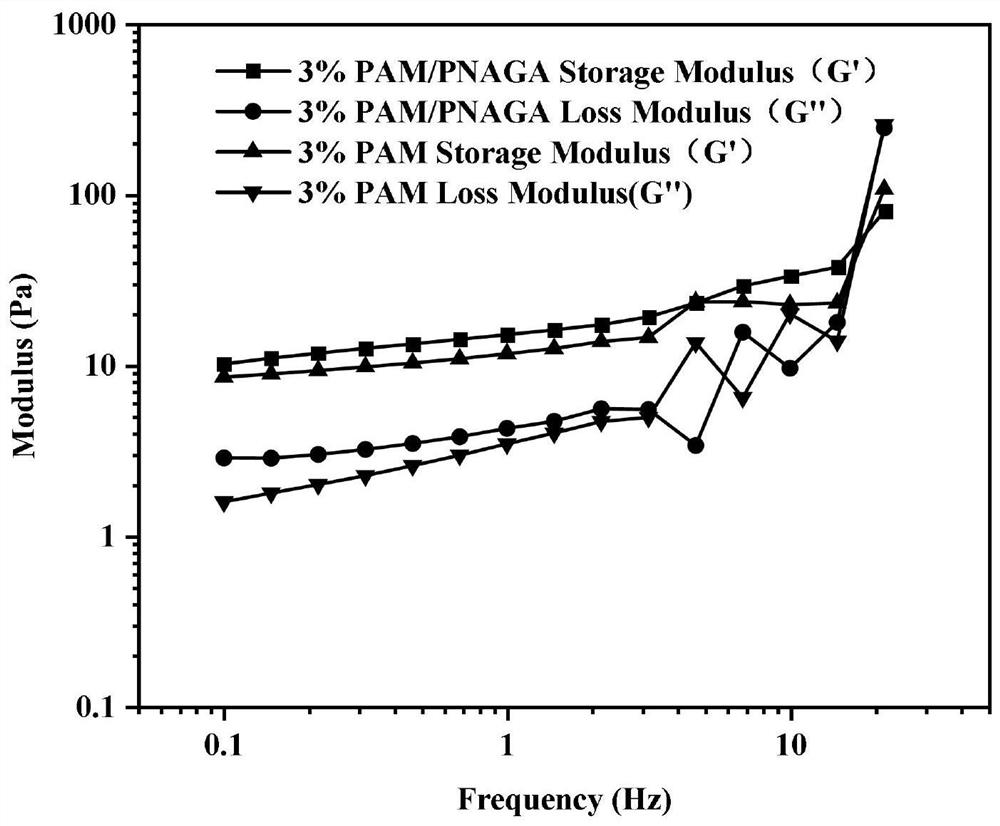

[0037] The shear-resistant and salt-resistant thickener obtained in Example 2 was formulated to compare with the viscoelasticity of ordinary polyacrylamide at the same concentration (3% by mass). see test results figure 2 with image 3 .

[0038] Such as figure 2 ...

Embodiment 3

[0040] This implementation provides a synthetic and optimized formula of a shear-resistant and salt-resistant fracturing fluid thickener:

[0041] The thickener is made of raw material components acrylamide, acryl glycinamide, N,N'-methylenebisacrylamide, ammonium persulfate, tetramethylethylenediamine, and deionized water. Among them, the mass of acrylamide and acryloyl glycinamide accounted for 1.5% and 1.60% of the total mass of all raw materials respectively. The mass of N,N'-methylenebisacrylamide accounts for 0.51% of the total mass of the two monomers of acrylamide and acrylglycylamide. The respective masses of ammonium persulfate and tetramethylethylenediamine account for 0.5% of the total mass of the two monomers of acrylamide and acryloylglycinamide.

[0042] The preparation method is the same as in Example 1.

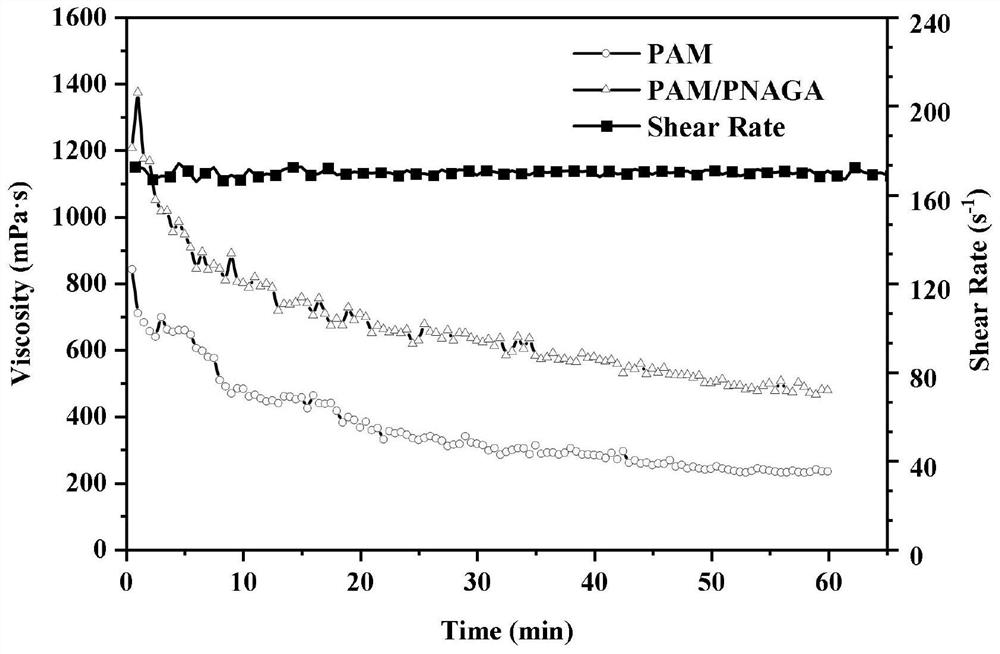

[0043] The shear-resistant and salt-resistant thickener obtained in Example 3 and common polyacrylamide were respectively prepared into solutions with a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com