A riveting device and method based on frequency conversion motor to control riveting head trajectory

A variable frequency motor and trajectory technology, applied in the direction of AC motor control, control system, electrical components, etc., can solve the problems of non-adjustable control, life concentration, difficulty in guaranteeing energy saving and emission reduction, and large energy consumption, so as to achieve energy consumption and use The effect of life optimization, simple and easy technical means, and reduced scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

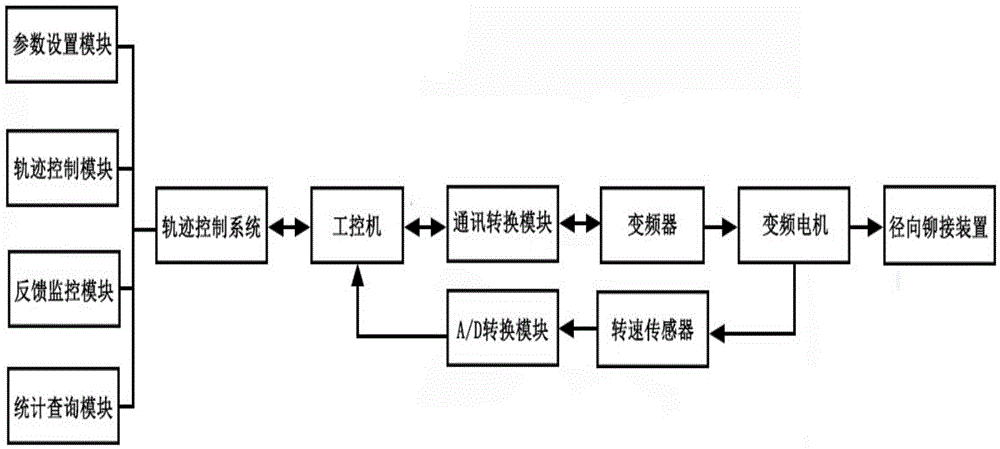

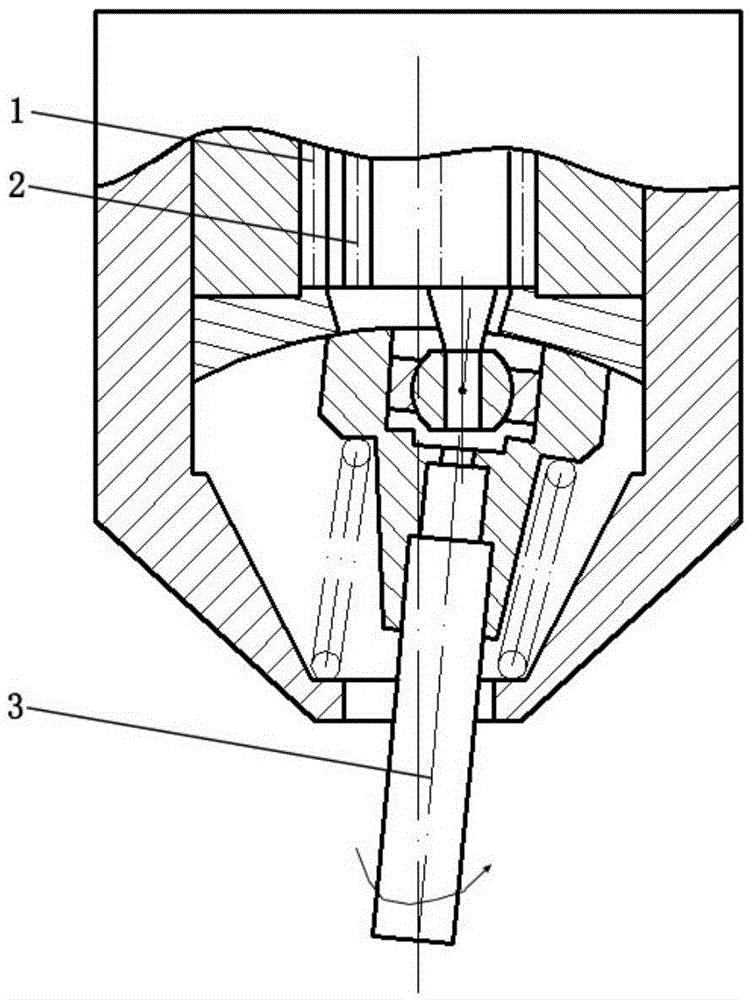

[0042] Such as Figure 1 to Figure 4 shown. The present invention is a riveting device for controlling the trajectory of a riveting head based on a frequency conversion motor, comprising a trajectory control system, an industrial computer, a communication conversion module, a frequency converter, a frequency conversion motor, and a radial riveting device connected in sequence;

[0043] The frequency conversion motor is connected to the industrial computer through the speed sensor and the A / D conversion module to form a closed-loop feedback control system.

[0044] The speed sensor is a voltage output sensor, which is installed on the output shaft end of the variable frequency motor, and converts the speed signal of the motor into a voltage signal, which is transmitted to the industrial computer through the data acquisition module, and the speed signal is calculated by the running state monitoring module in the trajectory control system analyze.

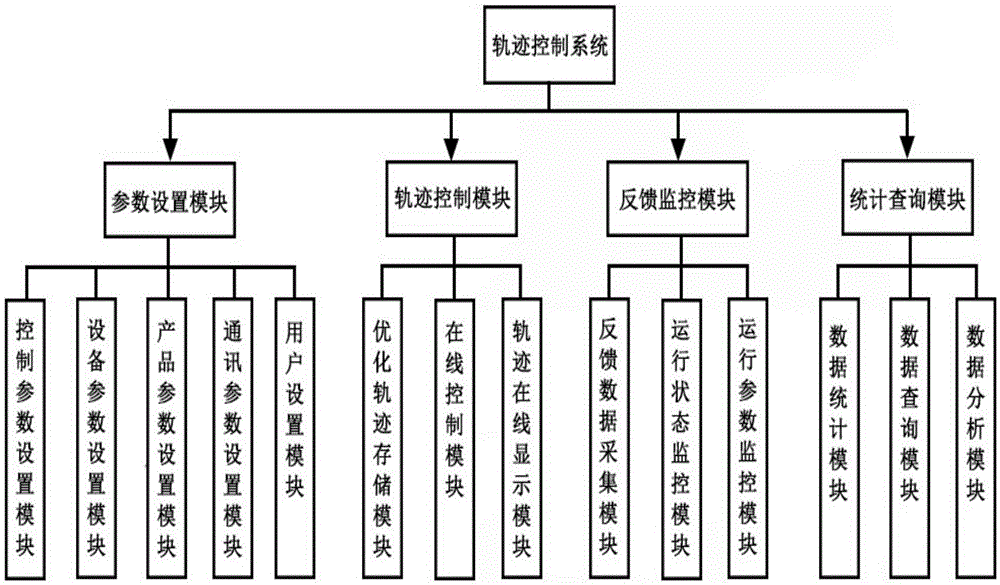

[0045] The trajectory contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com