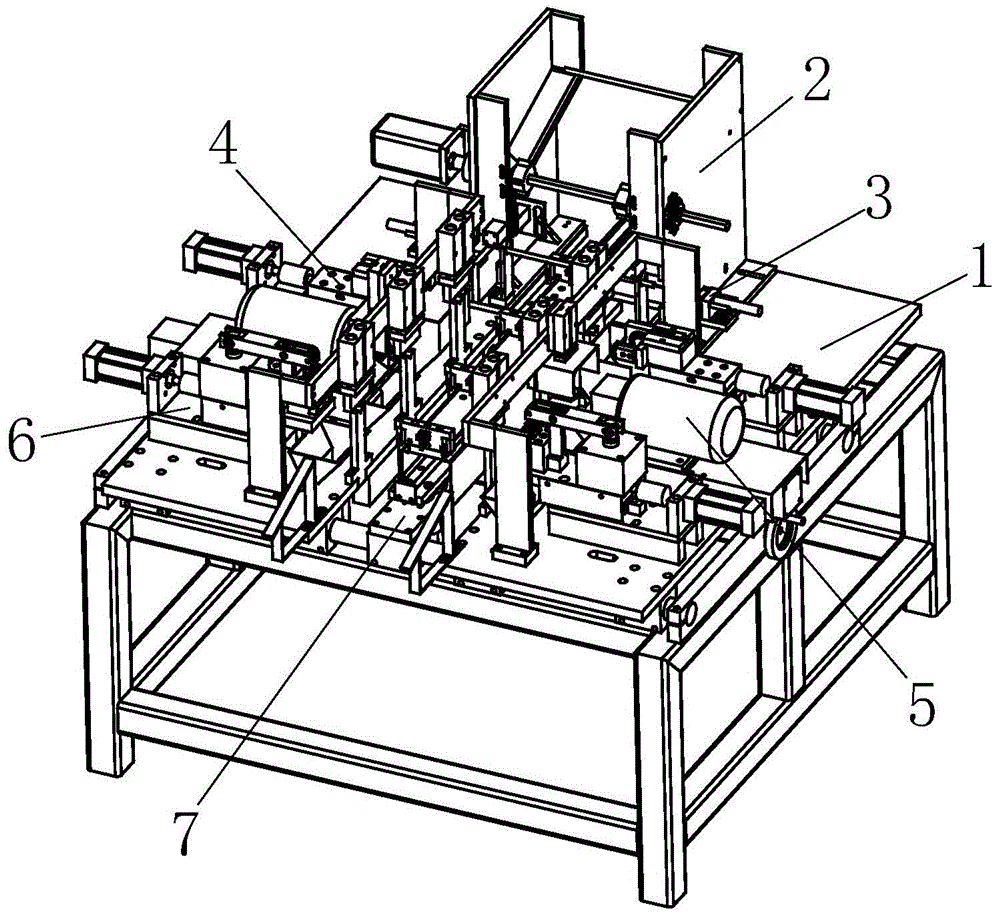

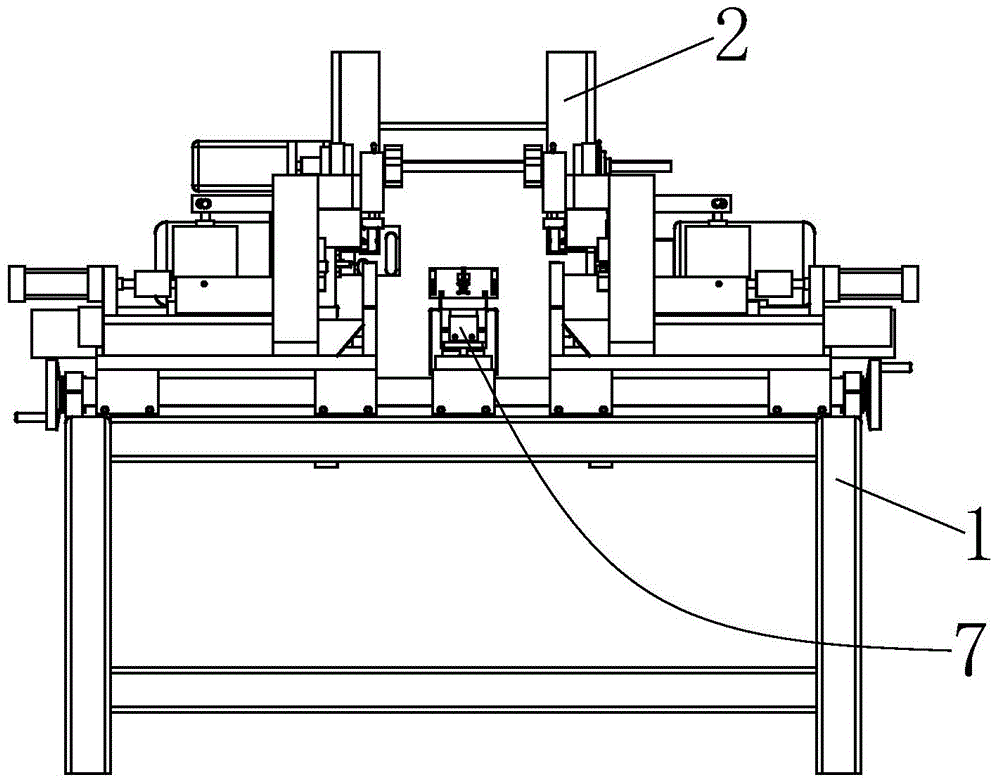

Aluminum pipe edge trimming machine tool

A technology for trimming and aluminum tubes, applied in automatic lathes/semi-automatic lathes, turning equipment, other manufacturing equipment/tools, etc., to achieve the effect of low processing cost, high degree of automation, time-saving and labor-saving production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

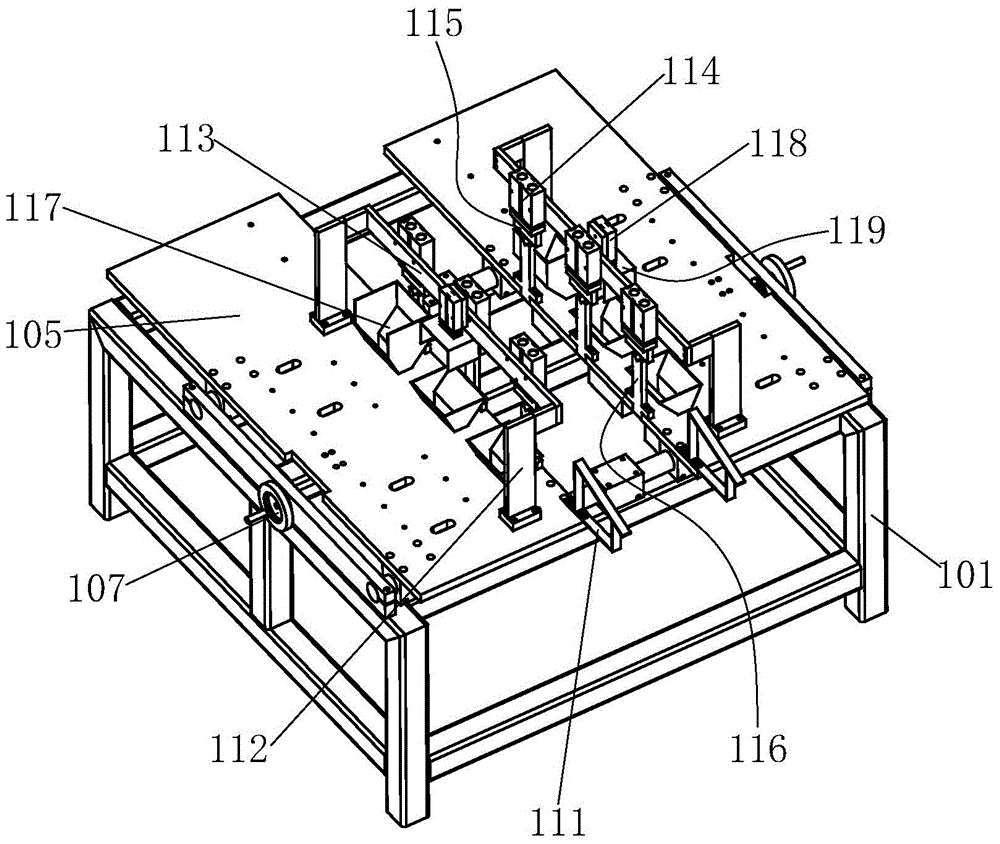

specific Embodiment approach

[0058] 1) Preparation before use:

[0059] First adjust the distance between the two sliding bases according to the length of the processed aluminum tube to facilitate processing. If the aluminum tube is short, turn the hand wheel 107 clockwise to drive the ball screw one 109 to rotate, and the connecting seat two 120 Under the action of thread transmission, the entire mounting plate 105 is driven to move to the middle position, so that the distance between the two mounting plates 105 becomes shorter. distance between.

[0060] The position of the clamp body 712 is adjusted through the feed system 7, and the specific method is: the lifting cylinder 706 pushes upward or drives the lifting plate 702 downward, and the vertical movement of the lifting guide column 703 and the lifting guide sleeve 705 can adjust the position of the clamp body 710. up and down position. The fifth cylinder 701 drives the mobile version 708 forward or backward through the floating joint three 707 of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap