Soft ear die punching tool and punching method using same

A technology of ear molds and tools, applied in the direction of manufacturing tools, boring/drilling, drilling/drilling equipment, etc. The rhythm and length of the return material, improve the processing efficiency, and avoid the effect of slipping and falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

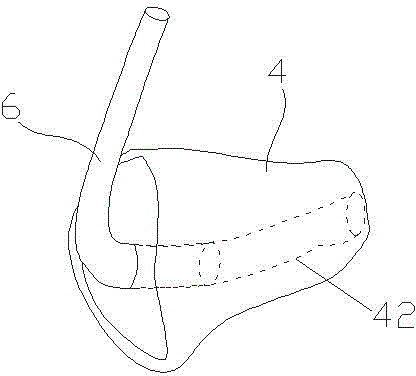

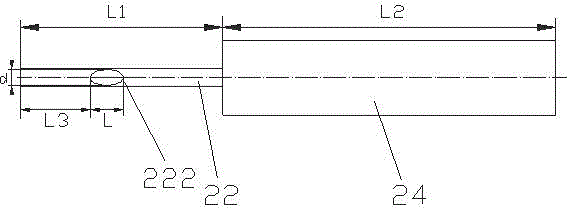

[0026] Such as Figure 1-4 As shown, a soft ear mold punching tool includes a longitudinal cutting part 22 and a handle 24 at one end of the cutting part 22 for grasping. The cutting part 22 is a rigid straight pipe with a wall thickness of 0.5-1mm, and a material ejection hole 222 is provided on one side of the cutting part 22 .

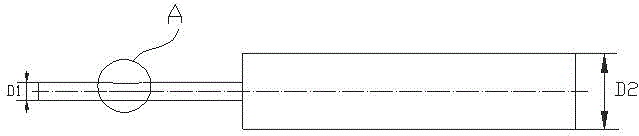

[0027] Specifically, the cutting part 22 is made of stainless steel, which is hard and durable. A pipe wall thickness of 0.5-1 mm can maintain a good cutting force on the soft ear mold 4 and reduce resistance. The axial length L1 of the cutting part 22 is 31.9mm, and the axial length L2 of the shank 24 is 52.5mm, so that the ratio of the latter to the former is 5.25:3.19-6.86:3.66, which is in line with the comfort of the human hand and is easy to use force , the cutting portion 22 has a suitable length for forming the soft ear mold 4 at one time, and the strength is also guaranteed. In this embodiment, the shank 24 is cylindrical, and the diamet...

Embodiment 2

[0030] Such as Figure 1-4 As shown, a soft ear mold punching tool differs from Embodiment 1 in that: the wall thickness of the cutting part 22 is 0.5-1 mm, the axial length L1 of the cutting part 22 is 36.6 mm, and the axial length L2 of the handle 24 It is 68.6mm. The diameter D2 of the shank portion 24 is 8.3 mm, and the outer diameter D1 of the cutting portion 22 is 2.4 mm. The distance L3 between the stripping hole 222 and the end of the cutting portion 22 away from the shank 24 is 16.7 mm, the length L of the stripping hole 222 along the axial direction of the cutting portion 22 is 4.3 mm, the width d is 1.6 mm, and the depth h is 0.2 mm.

[0031] Punching tools of this size are more suitable for, but not limited to, punching soft ear molds for children.

[0032] The following describes the method for punching holes using the soft ear mold punching tool of the present invention including the above-mentioned embodiments 1-2: fix the soft ear mold 4 and drill the cutting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com