A mold for thermocompression forming of the heat-proof layer of the guide head compartment

A technology of thermoforming and heat-proof layer, which is applied in the field of thermoforming molds, can solve problems such as uneven temperature and unqualified molded products, and achieve the effects of high operability, stable quality of molded products, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

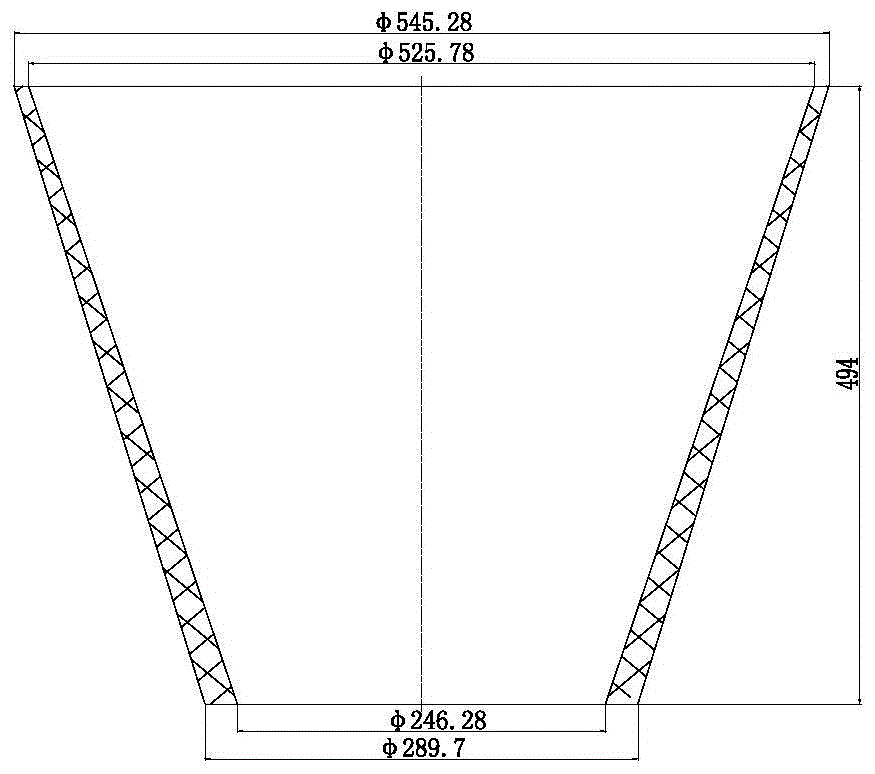

[0048] like figure 1 As shown in the figure, the heat-resistant layer of the seeker cabin is a conical revolving body, which has a large external dimension and high precision requirements. After molding, the inner and outer surfaces are not allowed to be processed.

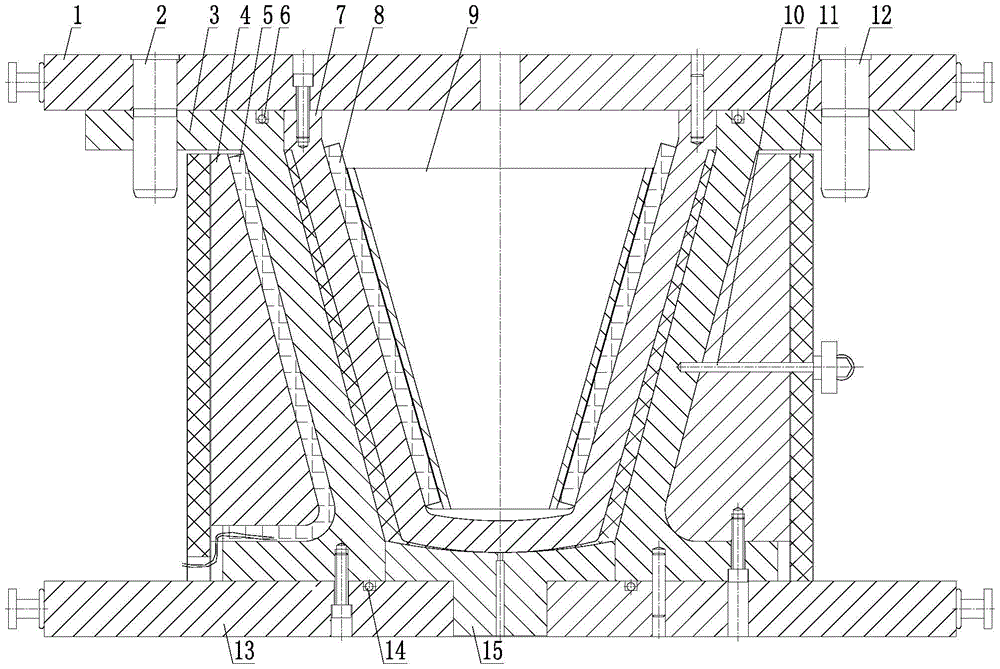

[0049] like figure 2 As shown, the embodiment of the present invention includes a concave die 3, an upper heating tube 6, a concave die heating plate 4, a concave die heating tube 5, a heat preservation sleeve 11, a lower template 13, a lower heating tube 14, a top block 15, a punch 7, Punch heating plate 9, punch heating tube 8 and upper template 1;

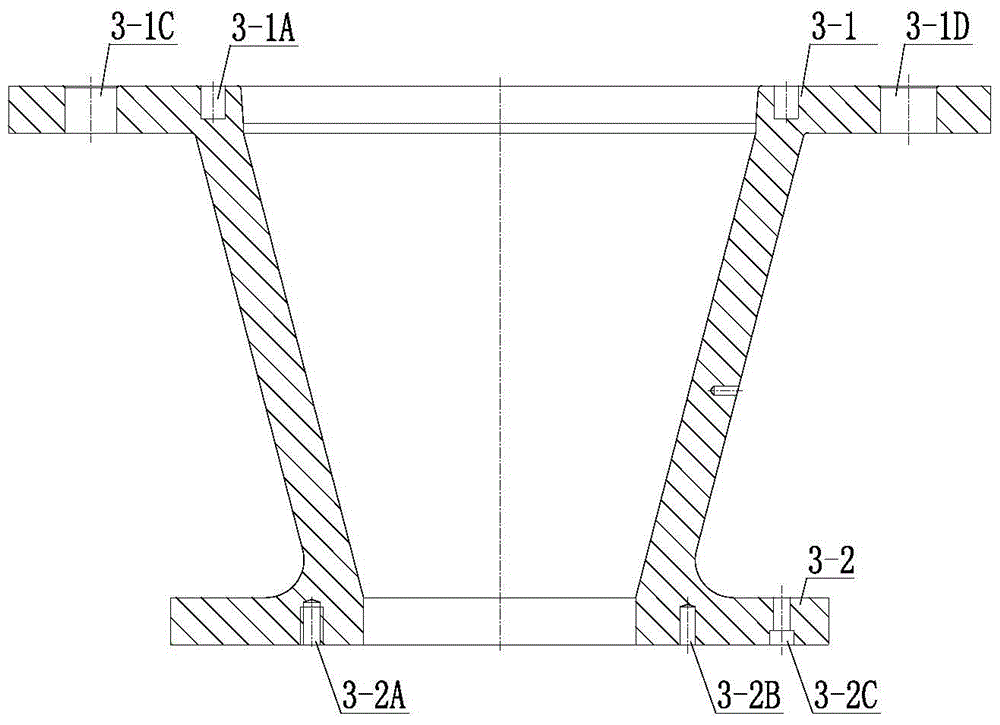

[0050] like image 3 , Figure 4 As shown, the female die 3 is a cone with a cavity, and its upper and lower end surfaces are turned radially outward to form an upper flange surface 3-1 and a lower flange surface 3-2, and the upper flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com