A car windshield wiper device

A windshield and wiper technology, which is applied in vehicle maintenance, vehicle cleaning, transportation and packaging, etc. It can solve the problems of low control accuracy, reduced wiper effect, and unfavorable use of the rotating shaft, so as to avoid head-to-head collision and reasonable structure , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

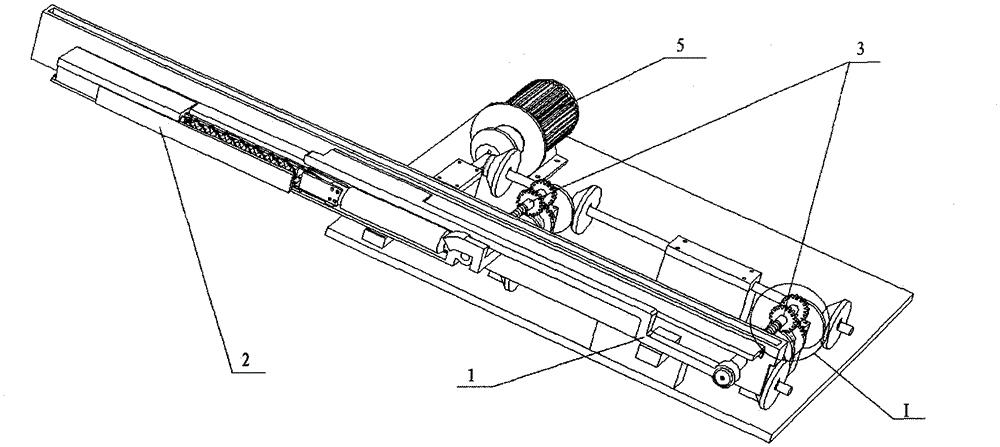

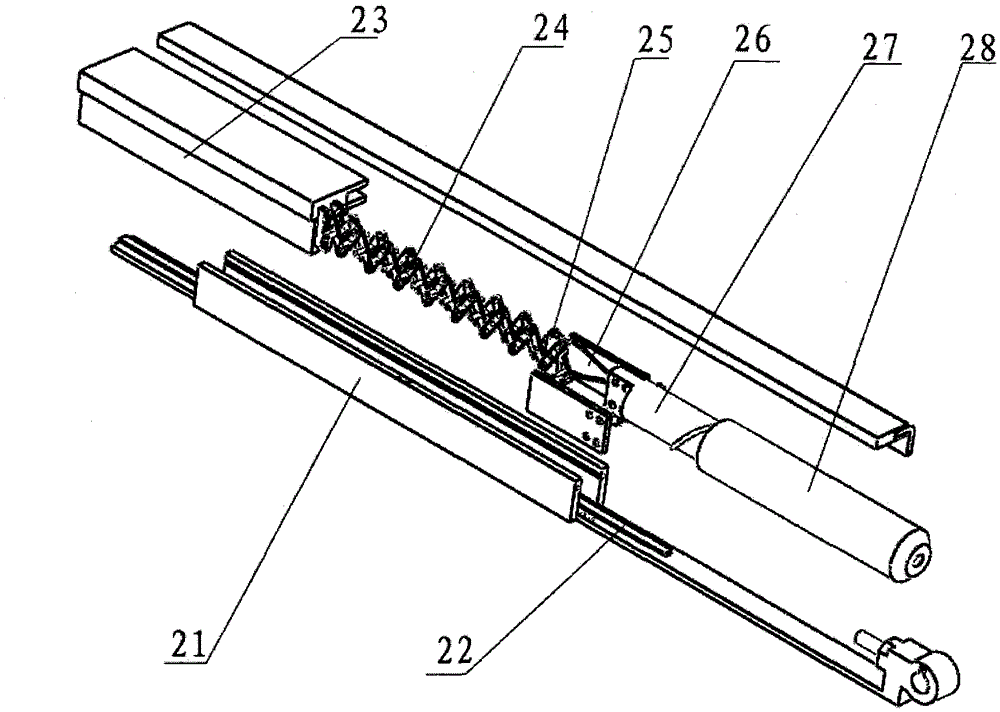

[0035] Such as Figure 1-4 Shown, a kind of windshield wiper device of automobile comprises upper wiper 1, lower wiper 2, wiper rotating shaft 3 and drive motor 5, and driving motor 5 drives upper wiper 1 and lower wiper 2 to carry out cleaning operation through wiper rotating shaft 3, its characteristic The reason is that the lower wiper 2 also includes a diamond-shaped telescopic mechanism. The diamond-shaped telescopic mechanism includes a strip-shaped bracket 21, the tail end of the strip-shaped bracket 21 is fixedly connected with the wiper shaft 3 through a keyway structure, and a propulsion drum 28, The sliding ejector rod 27 that has a long-pitch thread fit with the propulsion drum 28, the track plate 26 fixed on the front end of the sliding ejector rod 27 and has a concave track inside for adjusting the length of the diamond-shaped telescopic frame, the fixed frame 25, the diamond-shaped The telescoping frame 24 and the wiper sliding block 23 are provided with a gear...

Embodiment 2

[0039] Such as Figure 7 As shown, on the basis of Embodiment 1, a hard spring 31 is provided at the middle position of the wiper shaft 3 .

[0040] The beneficial effect of this embodiment is that: the hard spring can provide a certain amount of cushioning to avoid head-to-head collisions between mechanism parts when failure occurs.

Embodiment 3

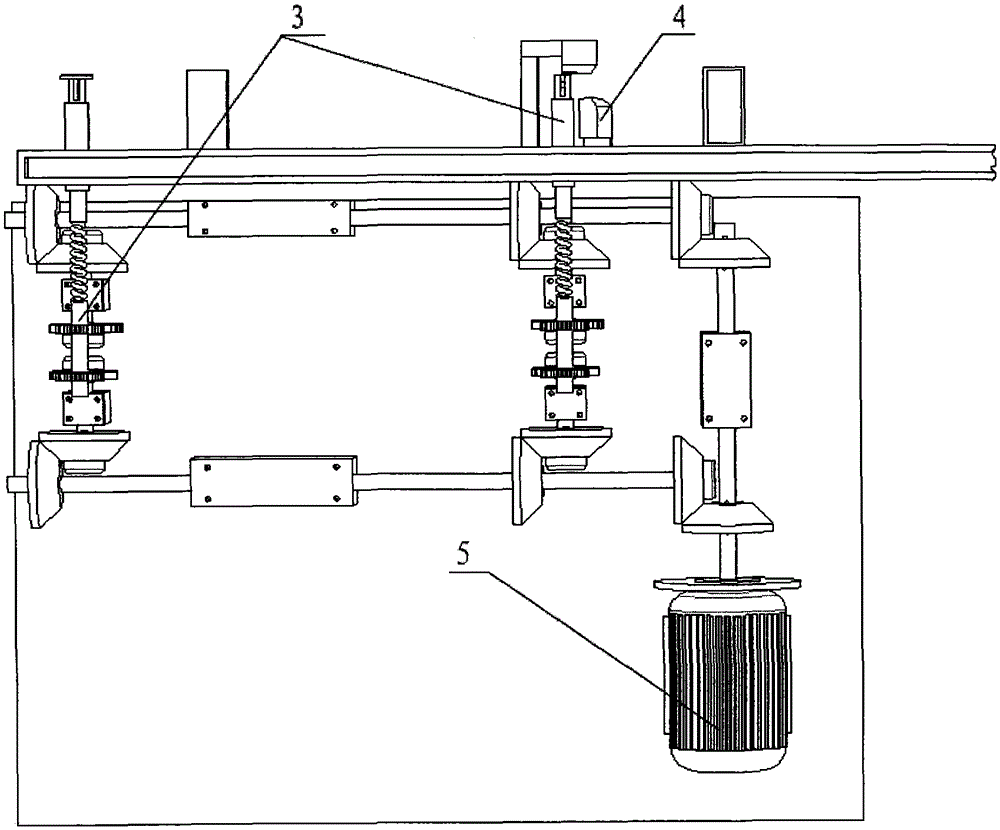

[0042] Such as Figure 5 , 6 As shown, on the basis of Embodiment 1, the drive motor 5 and the wiper shaft 3 are meshed through a pair of incomplete gears 6 with completely opposite motion directions. Stages of pause and drive. Two gears at different positions on each wiper rotating shaft 3 mesh with two incomplete gears 6 respectively. The reassembly method adjusts the phase difference of the two incomplete gears 6 .

[0043] The beneficial effect of this embodiment is that: the incomplete gear 6 provides a short stay of the wiper during operation, which facilitates the separation of rainwater on the wiper and avoids secondary pollution of the windshield. In addition, the spline-connected incomplete gears can facilitate the adjustment of the mating angle, so that the meshing angle can be adjusted according to the user's needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com