Two-stage and three-stage snub brake main valve provided with filter screen for Dongfeng 140

A brake master valve and belt filter technology, applied in the directions of brakes, brake components, control valves and air release valves, etc., can solve the problems of solid particles entering, affecting valve core sealing, gas pollution, etc., reducing the processing difficulty, The effect of avoiding braking accidents and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

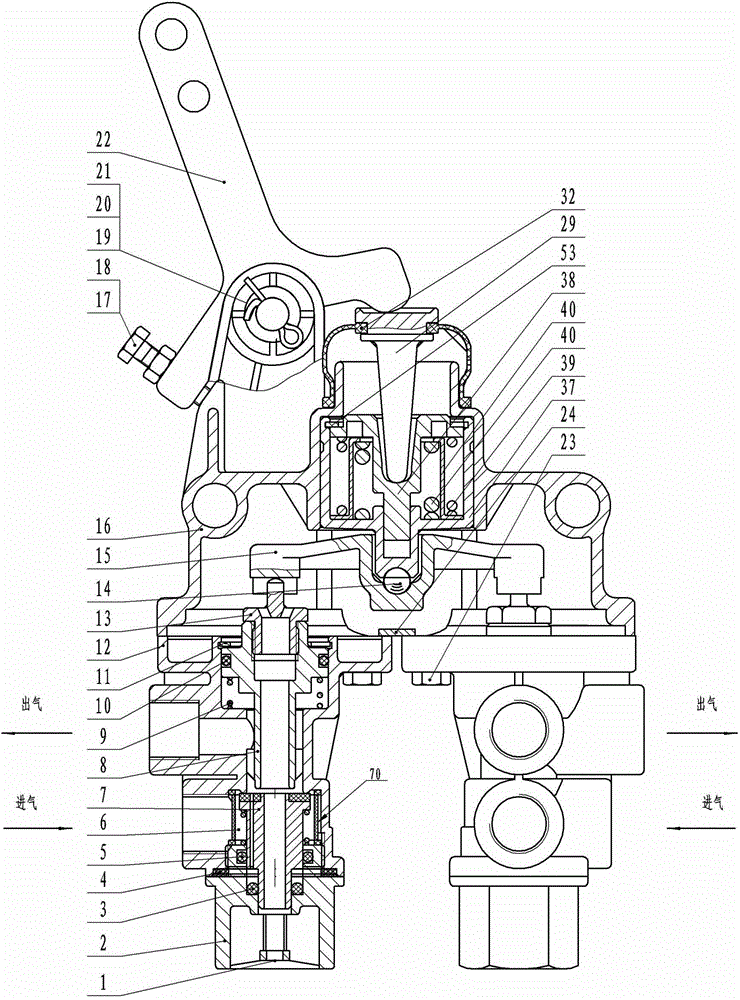

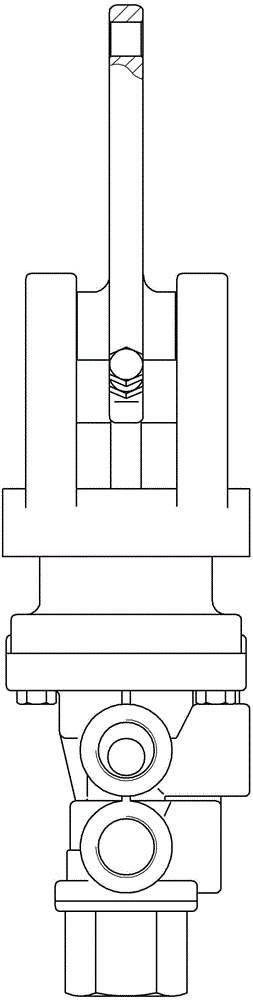

[0036] Embodiment 1: A two-stage point brake master valve with a filter screen for Dongfeng 140, see figure 1 and figure 2 , including the upper body and lower body, as well as tappets, tappet seats, pistons and valves.

[0037] There is an inner cavity in the upper middle of the upper body, and a balance piston is set in the inner cavity, and the balance piston is positioned by a circlip; the upper part of the balance piston is a cylindrical disc chamber A, and the lower part of the balance piston extends The hollow-shaped protrusion is the rod chamber B;

[0038] see Figure 4 , the upper part of the balance piston is a cylindrical disc chamber A, and the cavity-shaped protrusion protruding from the lower part of the balance piston is a rod chamber B.

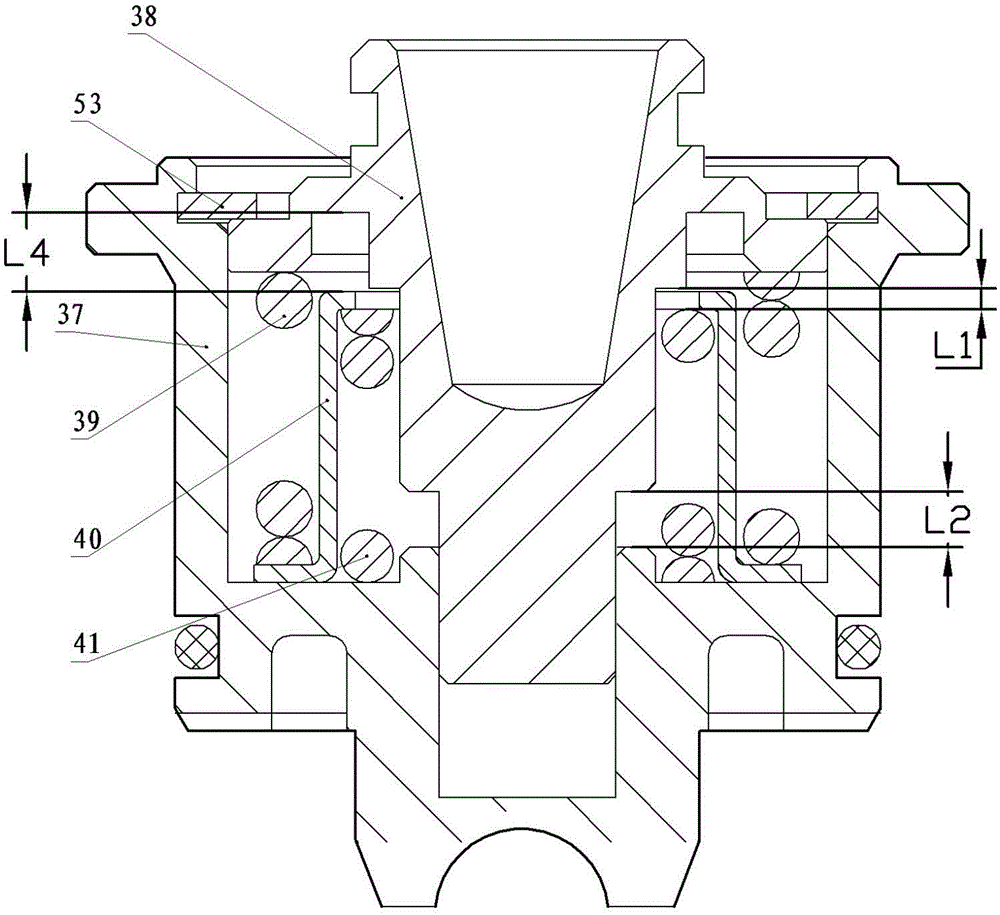

[0039] see Figure 7 and Figure 8 , the upper part of the tappet seat 38 is the disc 3801, and the lower part is the successively thinner three-stage step rod body protruding from the disc 3801, and the first rod body ...

Embodiment 2

[0048] Embodiment 2: A three-stage point brake master valve with a filter screen for Dongfeng 140, the content is basically the same as that of Embodiment 1, the difference is: see Figure 9 , replace the two-stage point brake balance piston assembly with the three-stage point brake balance piston assembly. see Figure 10, the three-stage point brake balance piston assembly includes a balance piston 37, a spring ferrule 40, a tappet seat 38, the top of the balance piston 37 is a cylindrical disc chamber A, and the bottom of the balance piston 37 protrudes from the space The cavity-shaped protrusion is the rod body chamber B; the upper part of the tappet seat 38 is a disc, and the lower part is a three-stage step rod body that protrudes from the disc 3801, and the first rod body is sequentially from top to bottom. 3803, the second rod body 3804, the third rod body 3805, the lower section of the third rod body 3805 is inserted into the rod body chamber B at the lower part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com