Steel wire hot-dip galvanization wiping and sink cooling device

A cooling device, hot-dip galvanizing technology, applied in hot-dip plating process, coating, metal material coating process, etc. Adjustable, good cooling effect, good wiping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific drawings and embodiments.

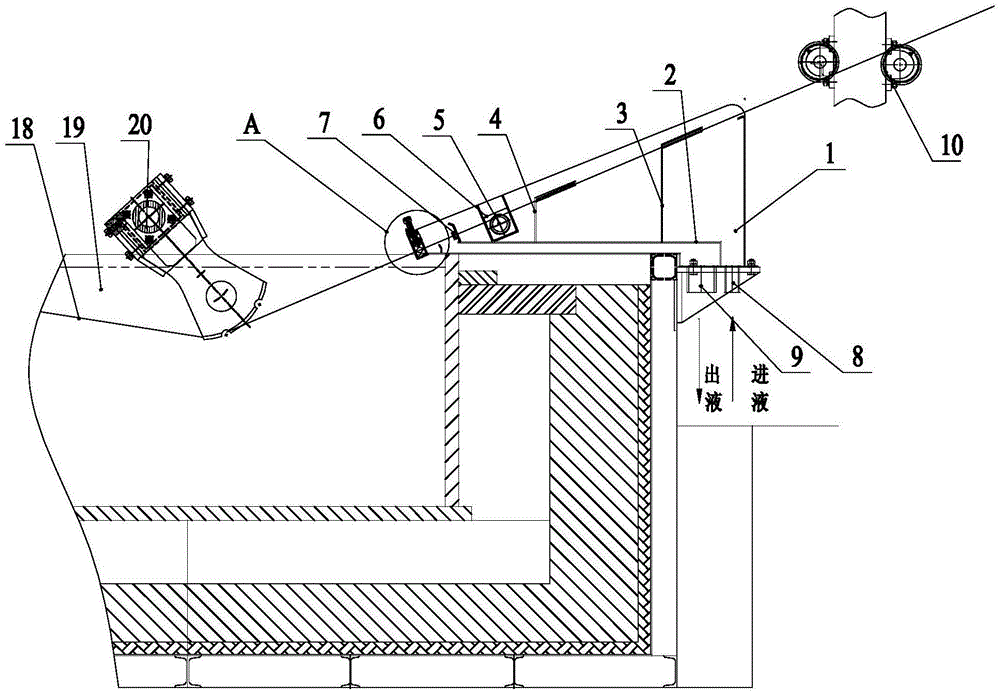

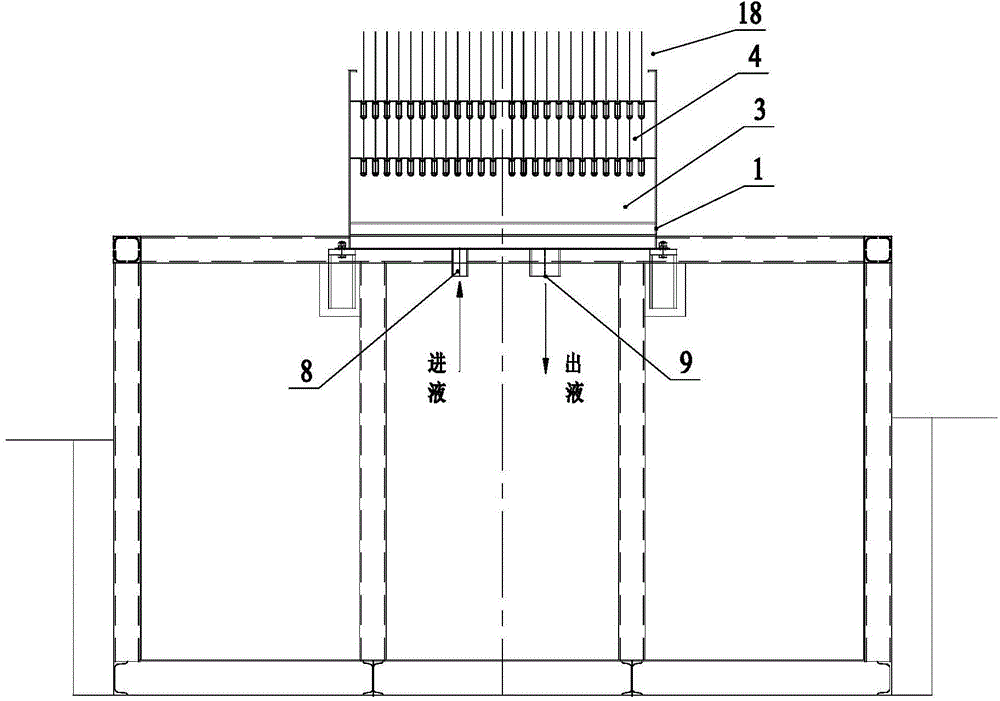

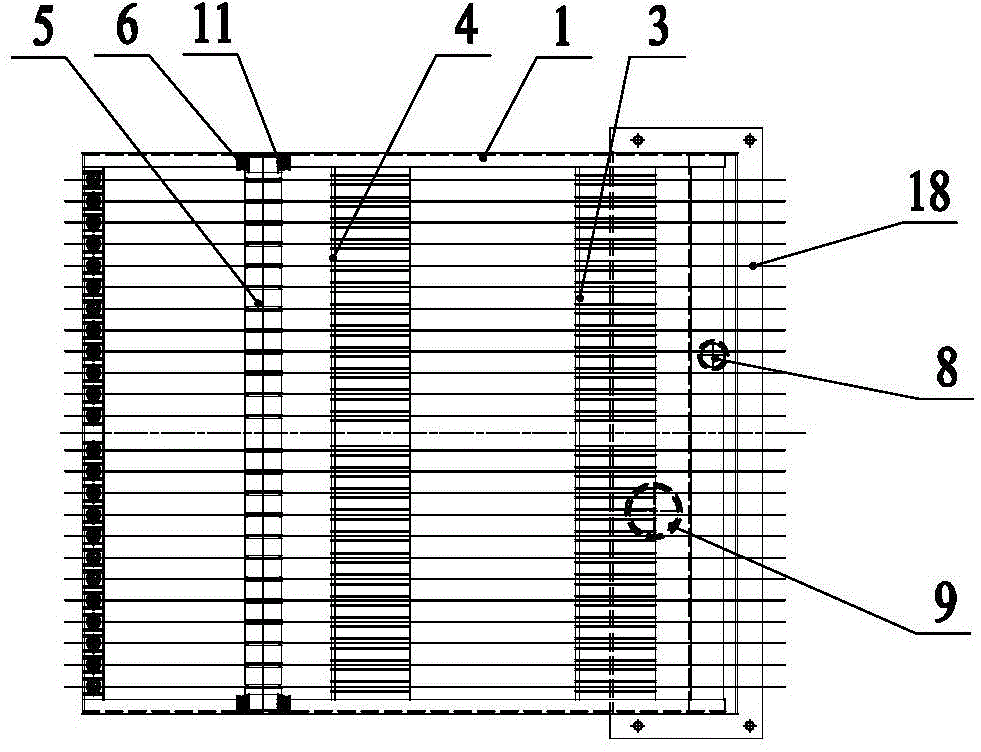

[0022] As shown in the figure: the steel wire hot dip galvanized wiping and water tank cooling device in the embodiment are mainly composed of a water tank body 1, a partition plate 2, a first cooling water plate 3, a second cooling water plate 4, a supporting roller 5, and a fixed Block 6, wear-resistant sleeve 7, liquid inlet 8, liquid outlet 9, supporting roller 10, wear-resistant ring 11, wiping asbestos block 12, perforated wiping asbestos block 13, pressing block 14, fixing nut 15, fine adjustment Screw 16 and water retaining plate 17 etc. are formed.

[0023] like Figure 1~Figure 3 As shown, the front end of the water tank body 1 is low and the rear end is high, and a partition 2 is provided near the bottom in the water tank body 1. The rear end of the partition board 2 is sealed and connected with the rear inner wall of the water tank body 1. There i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com