Metallographic etching solution for medical titanium alloy bone fracture fixation plate and etching method

A bone plate and titanium alloy technology, applied in the field of bone joint implants, can solve the problems of indistinguishable tissue morphology, no metallographic corrosion liquid, blurred grain boundaries, etc., and achieve the effects of simple formula, reduced hazards, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

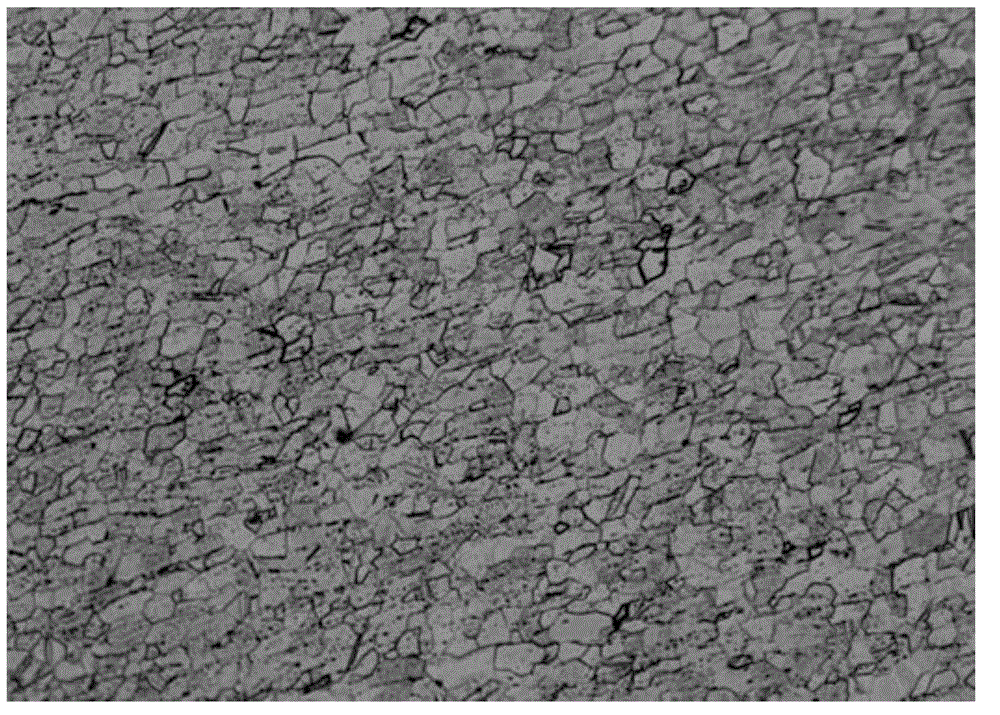

[0027] The first embodiment is to use hydrofluoric acid (49% by mass percentage, analytically pure), nitric acid (70% by mass percentage, analytically pure) and water in the volume of 1ml, 2ml, 47ml to prepare the etching solution, at room temperature Soak the polished titanium alloy bone plate in the corrosive solution for 45S, and then take out the titanium alloy bone plate, immediately rinse with clean water (may be tap water), then rinse with absolute ethanol, and then dry it with a hair dryer in cold air. The appearance of the metallographic structure obtained by microscope observation figure 1 . From figure 1 It can be seen that the metallographic structure obtained is clear and complete.

Embodiment 2

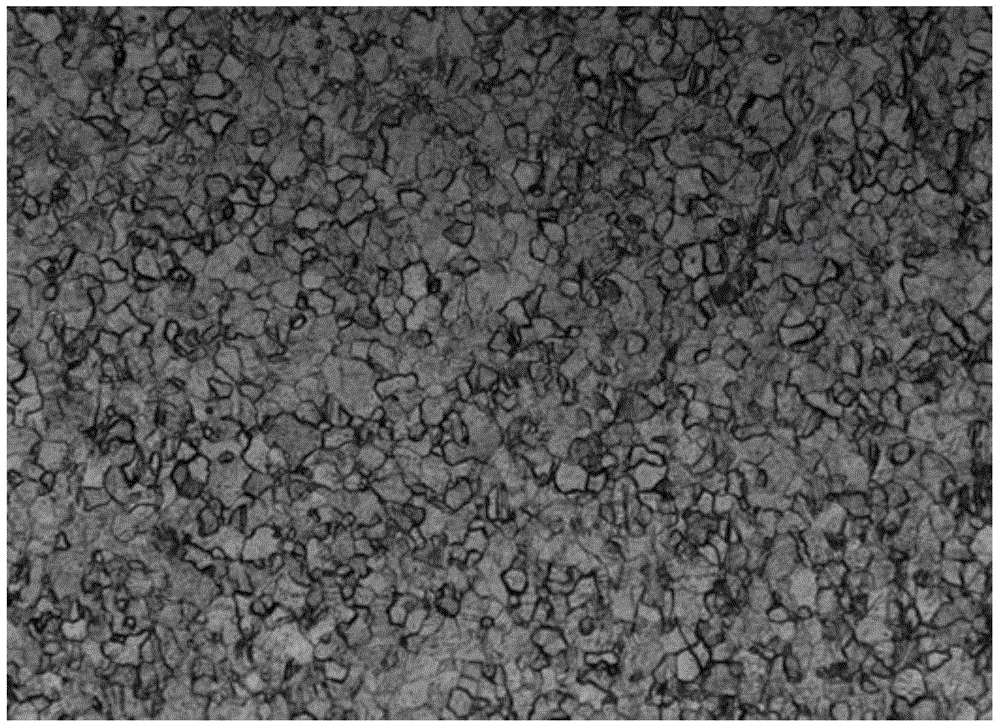

[0028] Example two, using hydrofluoric acid (weight percentage concentration of 49%, analytically pure), nitric acid (mass percentage concentration of 70%, analytically pure), and water were used in the volume of 2ml, 5ml, 93ml to prepare the corrosion solution, at room temperature Soak the polished titanium alloy bone plate gold in the corrosive solution for 30 seconds, then take out the titanium alloy bone plate, immediately rinse with clean water (may be tap water), then rinse with absolute ethanol and dry it with a hair dryer. The initial observation of the metallographic microscope in the metallographic microscope is not clear. After the second polishing, etching, cleaning and drying, the appearance of the metallographic structure observed afterwards is shown figure 2 . From figure 2 It can be seen that the metallographic structure obtained is clear and complete.

Embodiment 3

[0029] Example three, using hydrofluoric acid (weight percentage concentration of 49%, analytically pure), nitric acid (mass percentage concentration of 70%, analytically pure) and water in the volume of 1ml, 3ml, 96ml to prepare the corrosion solution, at room temperature Soak the polished titanium alloy bone plate gold in the corrosive solution for 20 seconds, then take out the titanium alloy bone plate, immediately rinse with clean water (may be tap water), then rinse with absolute ethanol and dry it with a hair dryer in cold air. The metallographic structure is obtained from the preliminary observation of the metallographic structure. In this embodiment, the amount of reagent is small, the cost is reduced, and the speed is fast, and the metallographic structure can be obtained quickly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com