Elastoplastic micro-expansion cementing cement slurry and preparation method thereof

A cementing cement slurry and micro-expansion technology, which is applied in the field of cementing slurry, can solve the problems of poor suspension stability and settlement stability, reduced compressive strength of cement stone, and difficulty in mixing cement slurry, so as to achieve the top strength quickly, Improve the flexural strength and impact toughness, good effect of slurry settlement stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Combine 100 parts of G grade cement, 1 part of 2-acrylamido-2 methylpropanesulfonic acid polymer, 3 parts of silica powder (purity ≥98%, particle size of 0.1μm-0.3μm), microbial polysaccharide synthetic gum 0.5 parts of suspension stabilizer, 2 parts of polypropylene elastic plasticizer, 2 parts of magnesium oxide expansion agent, and 35 parts of silicon powder are mixed and stirred to obtain a dry mixed material;

[0030] Dissolve 1 part of 2-acrylamido-2 methyl propanesulfonic acid polymer retarder and 0.2 part of polyether defoamer in 44% water and stir evenly to obtain a wet mixed material;

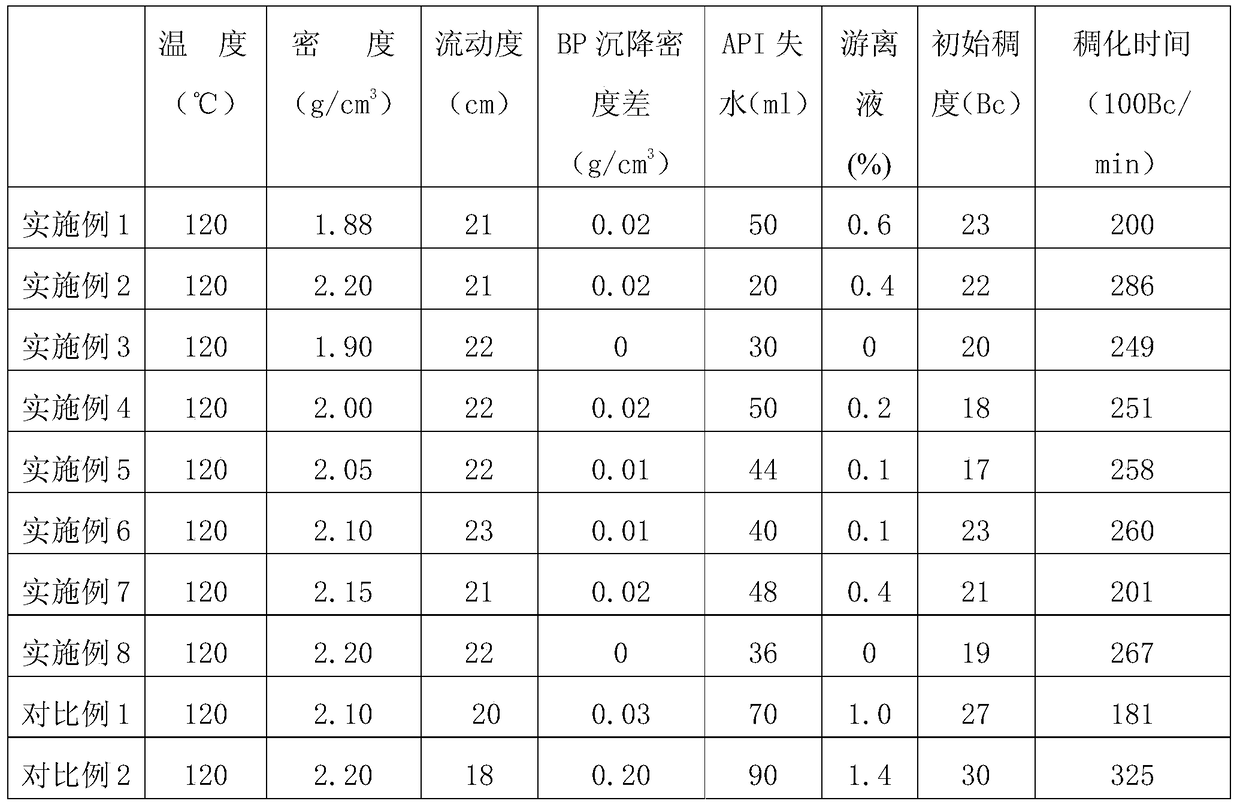

[0031] Under the stirring condition of 4000 revolutions / min, the dry mixed materials are added to the wet mixed materials at a uniform speed (15s), and then stirred at 12000 revolutions / min for 35s evenly and defoamed. The prepared cement slurry is elastic and plastic Micro-expansion cement slurry. The performance of the above cement slurry was measured, and the results are shown i...

Embodiment 2

[0033] Combine 100 parts of G grade cement, 50 parts of iron ore powder, 5 parts of 2-acrylamido-2-methylpropanesulfonic acid polymer, and silica powder (purity ≥98%, particle size 0.1μm-0.3μm) 10 2 parts, 2 parts of aliphatic hydroxysulfonate condensate, 2 parts of microbial polysaccharide synthetic gum suspension stabilizer, 8 parts of polypropylene plasticizer, 5 parts of magnesium oxide expansion agent and 45 parts of silicon powder are mixed and stirred to obtain Dry mix material

[0034] Dissolve 3 parts of 2-acrylamido-2 methyl propanesulfonic acid polymer retarder and 0.2 part of polyether defoamer in 110 parts of water and stir evenly to obtain a wet mixed material;

[0035] Add the dry-mixed material to the wet-mixed material at a uniform speed (15s) under stirring at a speed of 4000 revolutions / min, and then stir at a speed of 12000 revolutions / min for 35s evenly and defoam. The prepared cement slurry is elastoplastic micro Expansive cement slurry. The performance of t...

Embodiment 3

[0037] Combine 100 parts of G-grade cement, 1.8 parts of 2-acrylamido-2 methylpropanesulfonic acid polymer, 3 parts of silica powder (purity ≥98%, particle size of 0.1μm-0.3μm), 0.8 parts of fat Group hydroxy sulfonate condensate, 0.8 parts of microbial polysaccharide synthetic gum suspension stabilizer, 3 parts of polypropylene plasticizer, 3 parts of magnesium oxide type expansion agent and 35 parts of silicon powder are mixed and stirred uniformly to obtain a dry mixed material;

[0038] Dissolve 1.2 parts of 2-acrylamido-2 methylpropanesulfonic acid polymer retarder and 0.2 parts of polyether defoamer in 55 parts of water and stir evenly to obtain a wet mixed material;

[0039] Add the dry-mixed material to the wet-mixed material at a uniform speed (15s) under stirring at a speed of 4000 revolutions / min, and then stir at a speed of 12000 revolutions / min for 35s evenly and defoam. The prepared cement slurry is elastoplastic micro Expansive cement slurry. The performance of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com