Copper plating device and electroplating method for printed circuit board with through holes

A printed circuit board and copper plating technology, which is applied in plating tanks, electrolytic processes, electrolytic components, etc., can solve problems such as poor uniformity of micropores with high thickness-to-diameter ratio, different update rates of electrolytes, and influence of electroplating uniformity, etc., to achieve Improve the uniformity of electroplating and the quality of the plated parts, increase the deposition rate of the coating, and improve the effect of labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific implementation examples

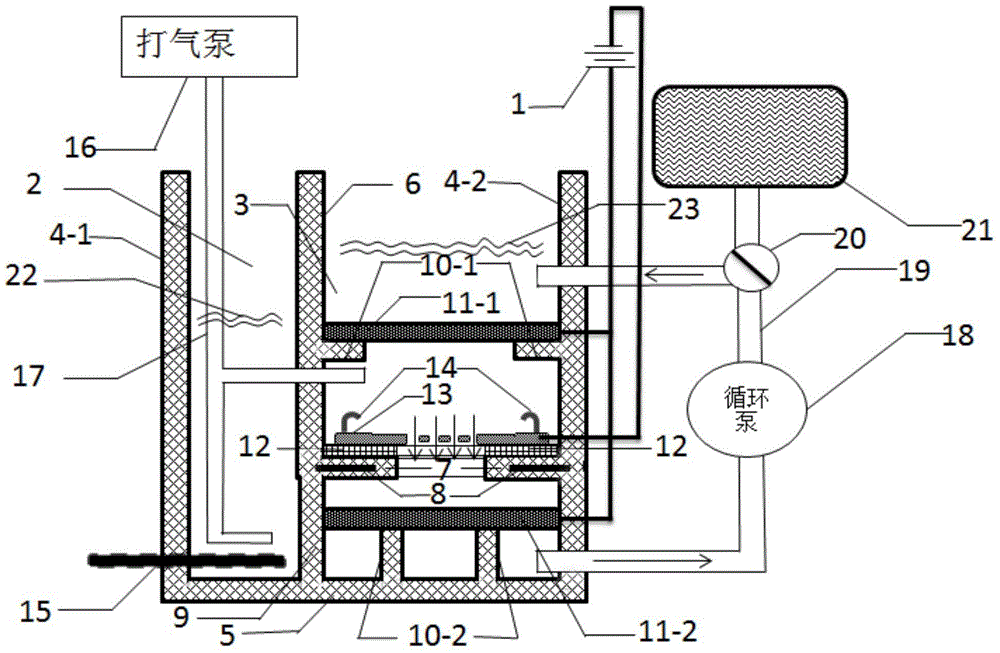

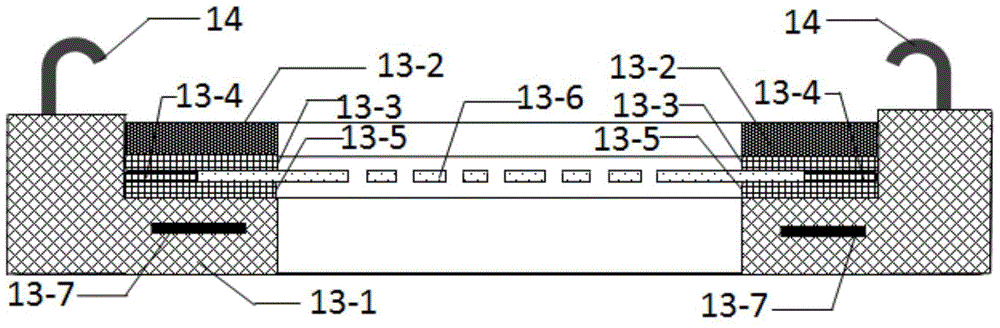

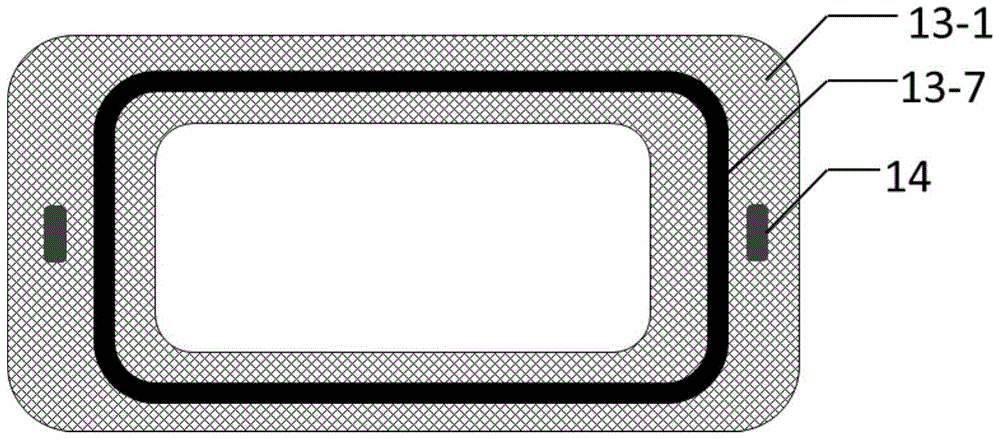

[0028] Such as figure 1 A copper plating device for through-holes of printed circuit boards with flowing electrolyte is shown, including: power supply (1), outer tank (2), inner tank (3), outer tank bottom (5), inner tank bottom (7), Magnetic body (8), inner tank support (9), upper anode support (10-1), lower anode support (10-2), upper anode (11-1), lower anode (11-2), elastic washer ( 12), cathode assembly (13), constant temperature heating device (15), air pump (16), air pipe (17), electrolyte circulation pump (18), electrolyte circulation pipe (19), tee (20) and reservoir (21). In consideration of material saving, the outer tank and the inner tank can share a part of the tank wall (4-2).

[0029] The bottom of the inner tank (7) is embedded with a magnetic body (8) and has a window, and the inner tank (3) is supported and fixed in the outer tank (2) by the inner tank bracket (9) placed on the bottom of the outer tank (5); The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com