Universal five-point support loading type tower crane foundation and construction method

A point-supported, general-purpose technology, applied in the foundation and construction field of general-purpose five-point-supported weight tower cranes, to reduce the demand for ground endurance, improve bending stiffness, and expand the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

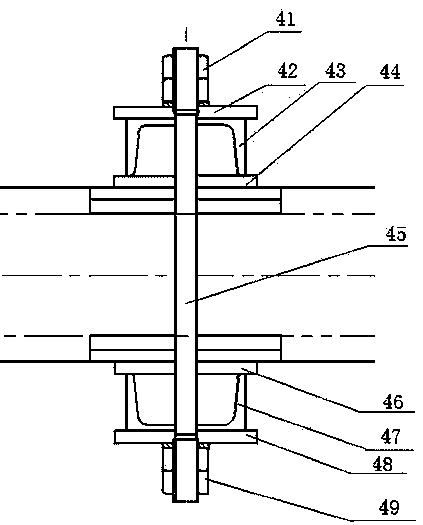

[0055] In this embodiment, an upper seat 55 is provided on the upper surface of the tower crane underframe, a lower seat 57 is provided on the lower surface of the underframe beam 23, and a vertical adjustment pad 59 is provided between the upper surface of the underframe beam 23 and the lower surface of the tower crane underframe. , the first bolt body 56 passes through two upper nuts 54, upper seat 55, tower crane underframe, spacer 59, underframe beam 23, lower seat 57 and is connected with two lower nuts 58 in sequence. The weight parts include a general weight block 25, an upper weight beam 30 and a lower weight beam 29 arranged sequentially from top to bottom, an upper splint 51 is arranged on the upper part of the upper weight beam, and a lower splint is arranged on the bottom of the lower weight beam 29 53, the weight bolt 52 passes through the lower clamping plate 53, the lower pressure beam 29, the upper pressure beam 30, and the upper clamping plate 51 successively a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com