Automotive oil pumping, collecting and oiling machine with self-supplied power source

A self-contained, power supply technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of increased workload, high price, small capacity of oil storage tanks, etc., and achieve extended service life, long service life, and capacity. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

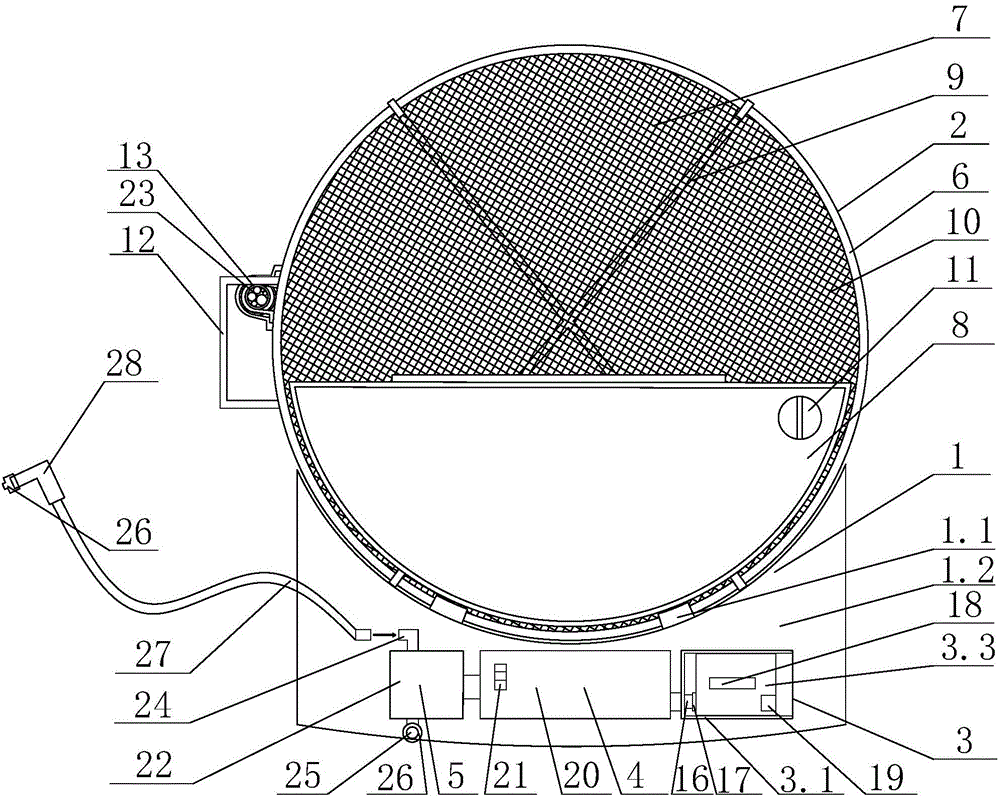

[0055] A pump oil dispenser with its own power supply for vehicles, which includes a support platform device 1 and an oil storage device 2, the support platform device 1 includes a support part 1.2 and is detachably connected to the oil storage device at the edge of the support part 1.2 The connection part 1.1 next to 2 is connected to the power supply device 3, the driving device 4, and the conveying device 5 in sequence on the support part 1.2.

[0056] In this embodiment, the supporting platform device 1 uses a steel plate as the supporting part 1.2, and the connecting part is composed of several inverted U-shaped barbs. The barbs can be hung on the container of the oil storage device. The side close to the oil storage device is fixed.

[0057] In this embodiment, an oil barrel is used as the oil storage device 2. Because it is easy to obtain materials and cheap in price, it can also be replaced by other containers. The oil barrel 6 is also provided with a tube 13 for placi...

Embodiment 2

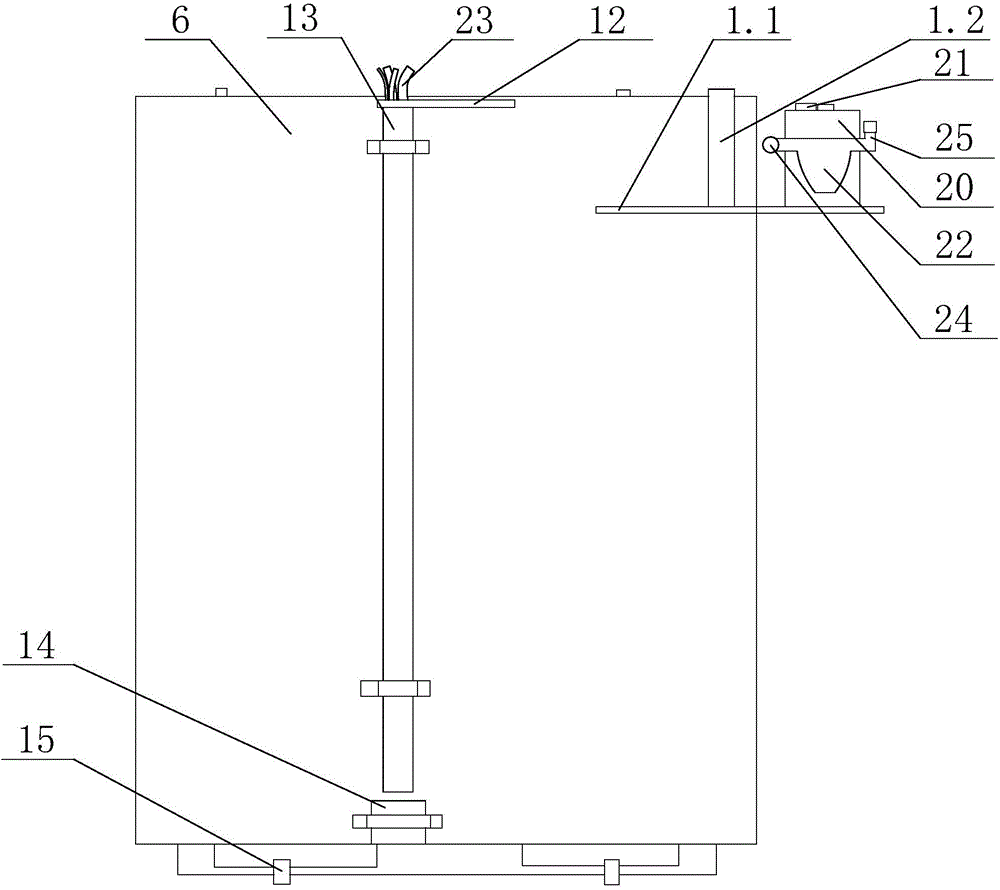

[0070] The structure of embodiment 2 is mostly the same as that of embodiment 1, the only difference is that the support platform device 1 is directly integrated on the oil barrel 6, and at the same time, the hose 27 and the oil outlet pipe 32 of the oil well pump 22 are connected. The corresponding changes are as follows:

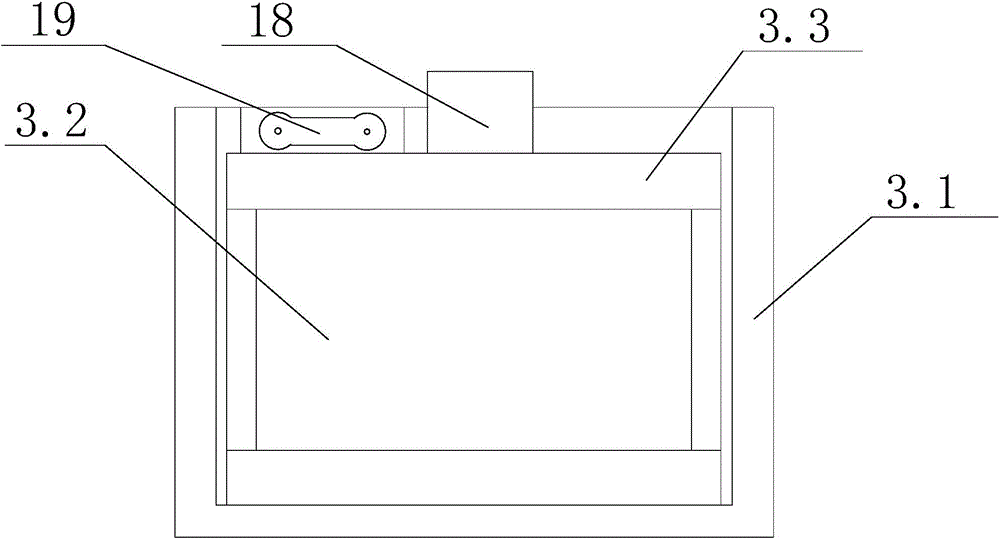

[0071] Such as Figure 6-9 As shown, the oil storage device 2 includes an oil barrel 6 with an upward opening, the support part is fixedly arranged on the oil barrel, and an oil filter mechanism 7 is arranged in the oil barrel 6 near the opening of the oil barrel. The mechanism 7 includes a filter screen 10, which is arranged at the opening of the oil drum. Be positioned at the opening of oil drum on the oil drum and be also provided with oil measuring drum 8, oil measuring drum 8 bottoms are provided with oil drain gate 11, and the side wall of oil measuring drum 8 is provided with oil level measuring window 33.

[0072] Such as Figure 7 and 10 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com