Novel air compression station system

An air compressor station, a new type of technology, applied in the direction of liquid variable capacity machinery, variable capacity pump components, machines/engines, etc., can solve the problem of affecting the stability and service life of the cold dryer, increasing the purchase cost of the cold dryer, and installation Cost transportation costs, maintenance costs, operating energy consumption, high ambient and inlet temperatures, etc., to achieve the effects of overall energy consumption and service life extension, reduced model selection, and lower air temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing with specific embodiment:

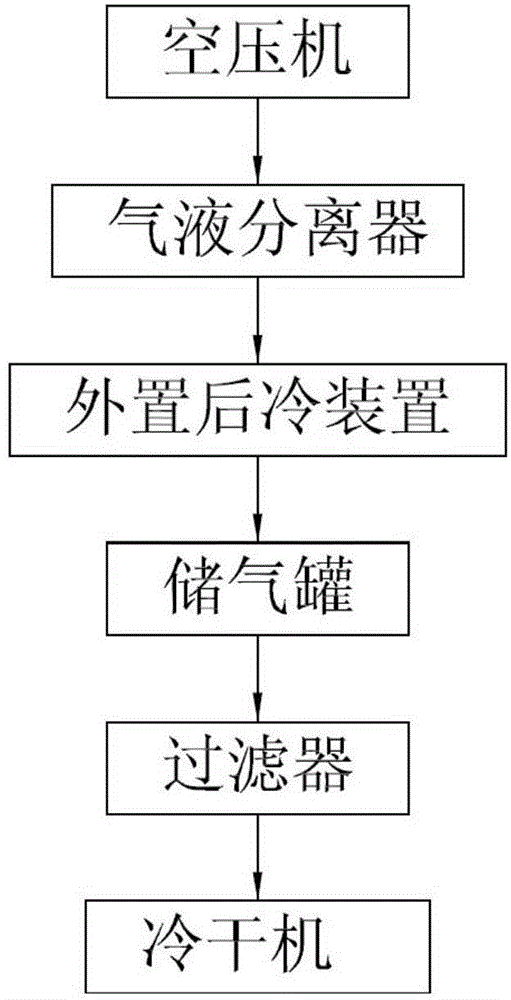

[0037] A new type of air compressor station system, including

[0038] Air compressor, which is used to inhale and compress the air in the surrounding environment, and then output high-pressure air to the outside;

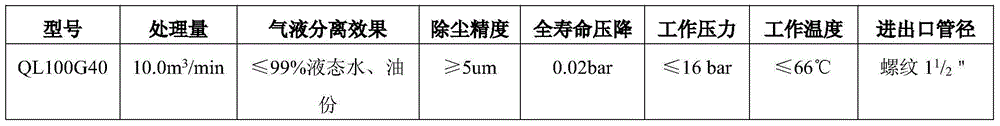

[0039] The gas-liquid separator, which is installed on the air outlet pipeline of the air compressor, is used to separate the condensate, oil and dust in the high-pressure air; the gas-liquid separator is used between the air compressor and the external aftercooling device, mainly Drainage and protection of the external aftercooling device do not play a decisive role in the quality of the final compressed air; after the high-temperature and high-pressure compressed air passes through the aftercooling of the air compressor body, a large amount of high-temperature condensate will be separated. Installing a gas-liquid separator at the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com