Critical load calculation method of parallel-shaft tooth-typed compressor

A critical load and calculation method technology, applied in the direction of machines/engines, etc., can solve problems such as abnormal unit vibration, car jumping, forced production stop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

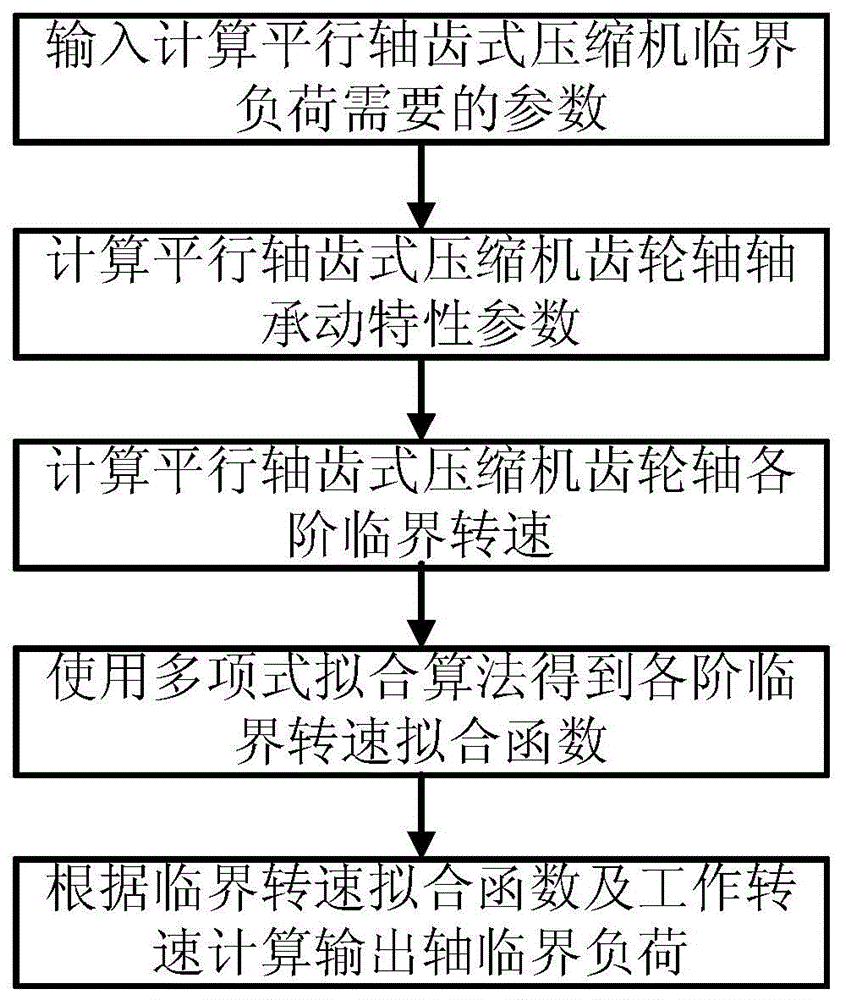

[0024] The flow chart of a method for calculating the critical load of a parallel-shaft gear compressor is as follows: figure 1 As shown, it mainly includes:

[0025] (1) Obtain the parameters of the parallel-shaft gear compressor that needs to calculate the critical load, including: the basic structural dimensions of each shaft of the parallel-shaft gear compressor, the position, mass, diameter moment of inertia and pole moment of inertia of each impeller, each gear The normal operating speed of the shaft, the installation angle of each gear, the installation position information of the gear, the diameter of the pitch circle, the helix angle and the pressure angle, and the rated operating power;

[0026] (2) According to the gear installation position of the gear shaft, pitch circle diameter, helix angle, pressure angle and rated operating power, calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com