Power generation system capable of recovering waste heat of rectifying tower air cooler

A waste heat recovery and power generation system technology, which is applied in the direction of machines/engines, steam generation, lighting and heating equipment, etc., can solve the problems of unreasonable and effective use of heat resources and high energy consumption of aromatic hydrocarbon complexes, etc., and achieve improvement Work efficiency, ensure flexibility, improve the effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

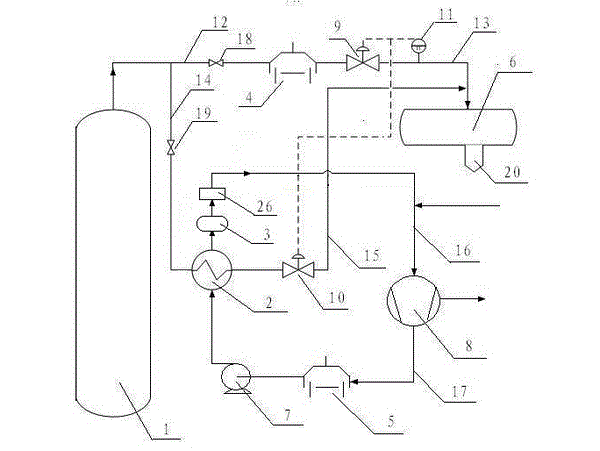

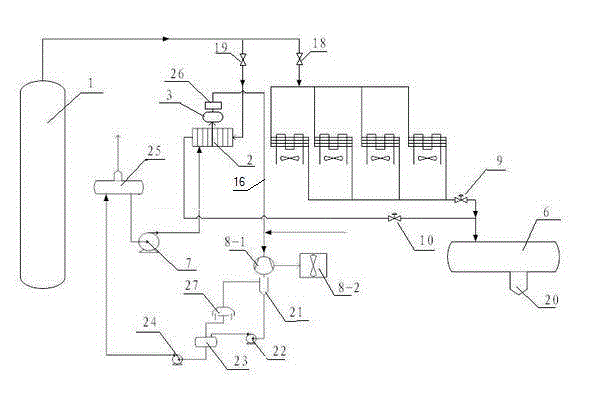

[0011] Rectification tower air cooler waste heat recovery power generation system, including rectification tower 1, material air cooler 4 and reflux tank 6, rectification tower 1 is connected to material air cooler 4 through first pipeline 12, material air cooler 4 is connected through second pipeline 13 The reflux tank 6 also includes a heat exchanger 2, a steam drum 3, a flash evaporator 26, a generator set 8 and a hot water circulation pump 7; the rectification tower 1 is connected to the heat exchanger 2 through a third pipeline 14, and the heat exchanger 2 passes through Four pipelines 15 are connected to the return tank 6; the heat exchanger 1 is also connected to the steam drum 3 through pipelines, and the steam drum 3 is connected to the flasher 26, and the flasher 26 is connected to the generator set 8 through the fifth pipeline 16, and the generator set 8 is connected through the sixth pipeline 17 The hot water circulation pump 7, the hot water circulation pump 7 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com