A halogen-free flame-retardant and cold-resistant PC material suitable for charging pile charging guns and its preparation method

A charging gun and charging pile technology, applied in the field of polymer functional composite materials, can solve the problems of large amount of addition, insufficient low-temperature impact, etc., and achieve the effect of less addition, less impact, and excellent impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

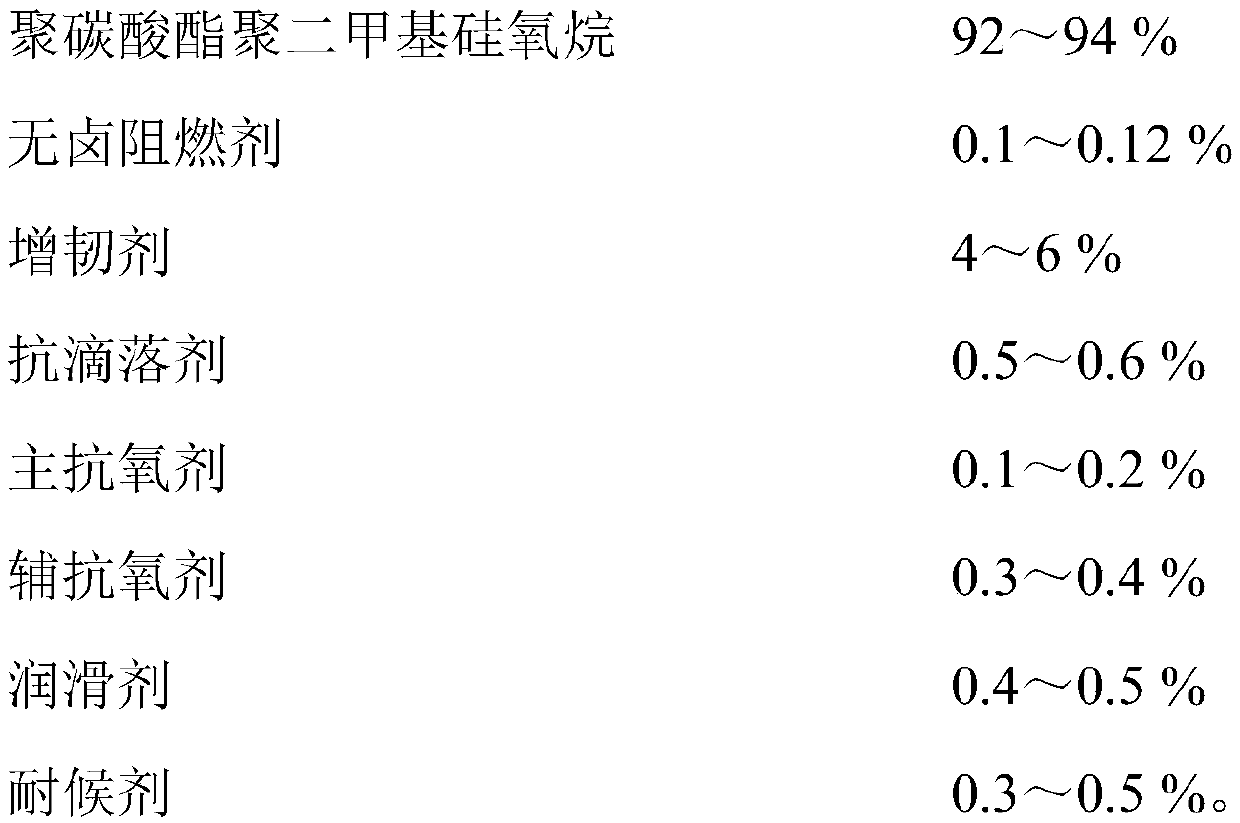

Method used

Image

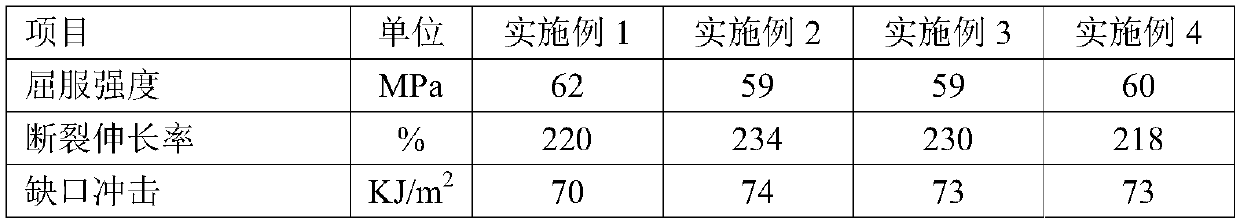

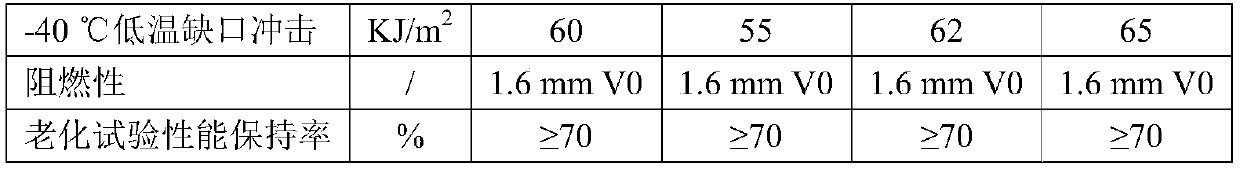

Examples

Embodiment 1

[0040]Weigh raw materials according to Table 1 and put them into a high-speed mixer, and mix at high and low speeds for 4 minutes at room temperature. The mixed material is put into the hopper of a twin-screw extruder, melted and blended, extruded and granulated to obtain a composite material. The processing technology is as follows: twin-screw extruder, the temperature of the first zone is 220°C, the temperature of the second zone is 260°C, the temperature of the third zone is 260°C, the temperature of the fourth zone is 260°C, the temperature of the fifth zone is 250°C, the temperature of the sixth zone is 240°C, and the temperature of the seventh zone is 230°C , the eight-zone temperature is 230°C, and the head temperature is 260°C. Screw speed: 400r / min, vacuum: 600mmHg, cooling water temperature: 50°C, drying time: 2h, drying temperature: 100°C.

Embodiment 2

[0042] Weigh raw materials according to Table 1 and put them into a high-speed mixer, and mix at high and low speeds for 4 minutes at room temperature. The mixed material is put into the hopper of a twin-screw extruder, melted and blended, extruded and granulated to obtain a composite material. The processing technology is as follows: twin-screw extruder, the temperature of the first zone is 220°C, the temperature of the second zone is 260°C, the temperature of the third zone is 260°C, the temperature of the fourth zone is 260°C, the temperature of the fifth zone is 250°C, the temperature of the sixth zone is 240°C, and the temperature of the seventh zone is 230°C , the eight-zone temperature is 230°C, and the head temperature is 260°C. Screw speed: 400r / min, vacuum: 600mmHg, cooling water temperature: 50°C, drying time: 2h, drying temperature: 100°C.

Embodiment 3

[0044] Weigh raw materials according to Table 1 and put them into a high-speed mixer, and mix at high and low speeds for 4 minutes at room temperature. The mixed material is put into the hopper of a twin-screw extruder, melted and blended, extruded and granulated to obtain a composite material. The processing technology is as follows: twin-screw extruder, the temperature of the first zone is 220°C, the temperature of the second zone is 260°C, the temperature of the third zone is 260°C, the temperature of the fourth zone is 260°C, the temperature of the fifth zone is 250°C, the temperature of the sixth zone is 240°C, and the temperature of the seventh zone is 230°C , the eight-zone temperature is 230°C, and the head temperature is 260°C. Screw speed: 400r / min, vacuum: 600mmHg, cooling water temperature: 50°C, drying time: 2h, drying temperature: 100°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com