Novel phosphorus-based flame retardant and halogen-free intumescent anti-flaming ABS (Acrylonitrile Butadiene Styrene) resin containing same

A phosphorus-based flame retardant and ABS resin technology, applied in the field of halogen-free intumescent flame-retardant ABS resin and phosphorus-based flame retardant, can solve the problems of high cost, complex production process, dependence on imports, etc., and achieve low smoke density, synthetic Simple method and good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The synthetic method of melamine salt of 2-carboxyethylphenylphosphinic acid

[0031]

[0032] In a 1000mL flask equipped with a mechanical stirrer, a thermometer, and a reflux condenser, add 23.5g (0.11mol) of CEPPA and 400mL of distilled water, stir to dissolve it completely, and then add 12.6g (0.1mol) of melamine to the flask Control the reaction temperature with 500mL distilled water at 80°C, and the reaction time is 4h. After the reaction was completed, it was cooled and filtered, washed and filtered repeatedly with distilled water, and air-dried at 80° C. for 12 hours to obtain CEPPAME as a white solid powder with a yield of 86%.

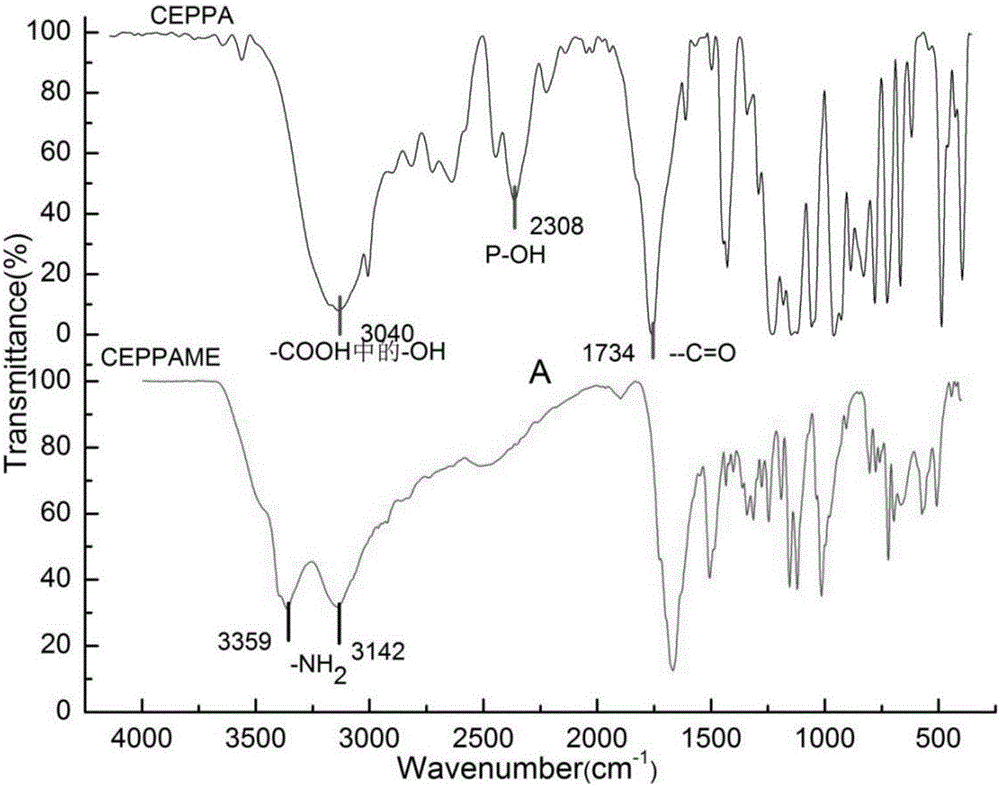

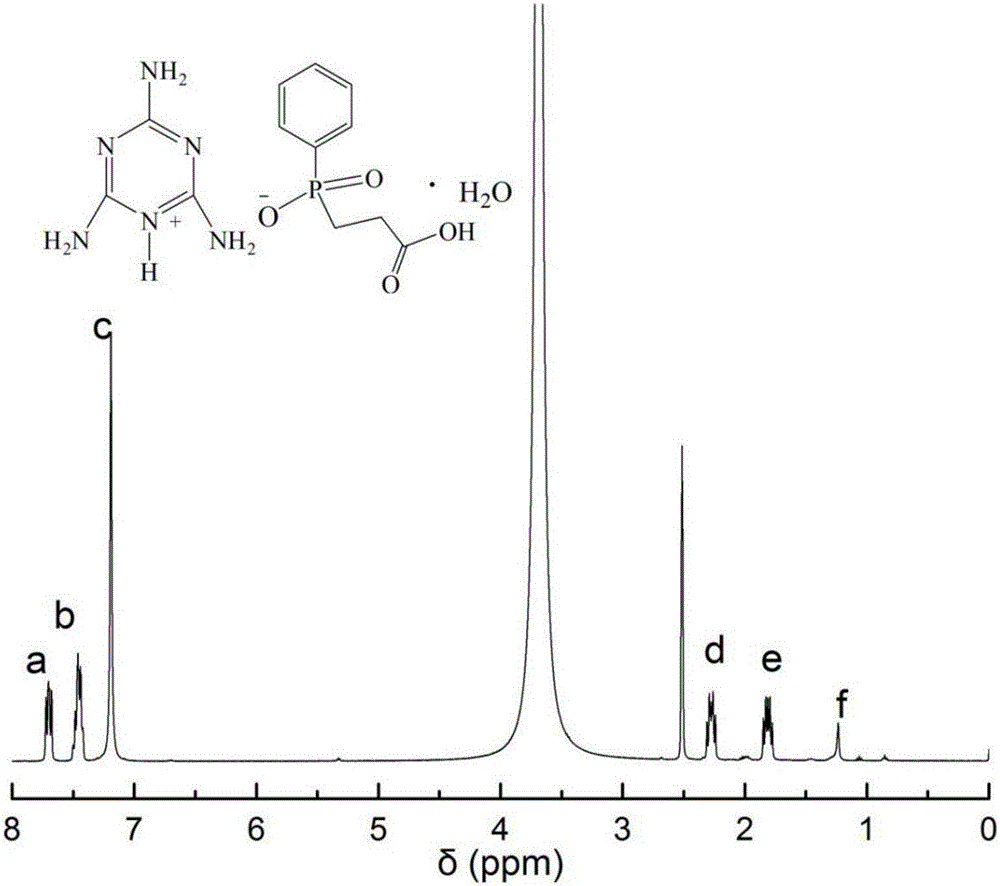

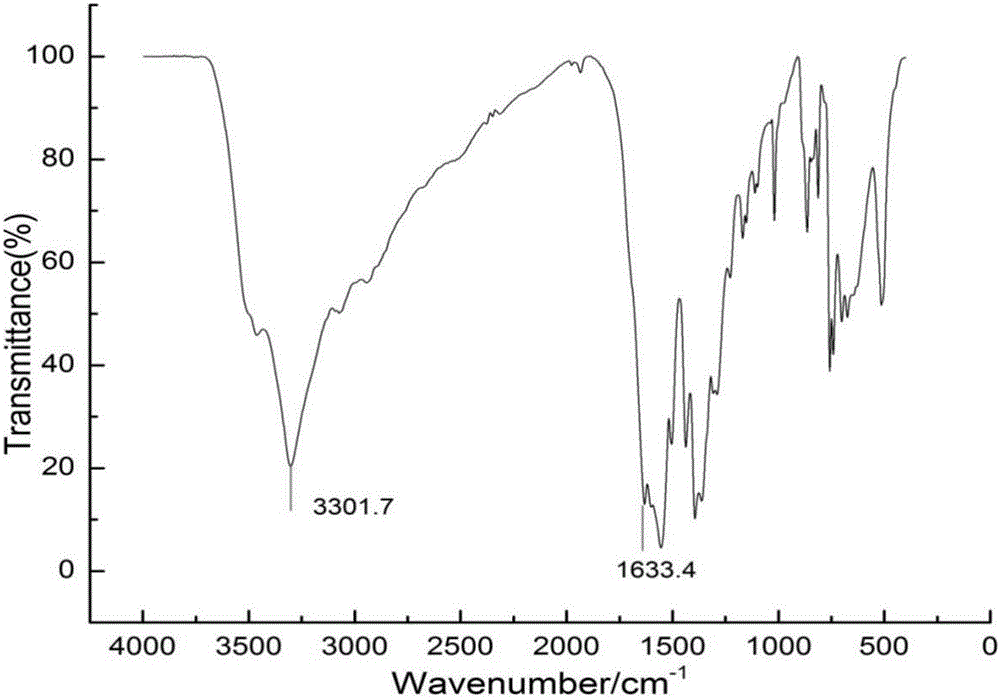

[0033] figure 1 Infrared spectra of CEPPA and CEPPAME, the reaction product of CEPPA and ME. Among them, the characteristic peak of CEPPA is: 1141cm -1 It is the stretching vibration peak of P=O, 1241cm -1 It is the stretching vibration peak of P-Ar, 1426cm -1 、1485cm -1 and 1592cm -1 It is the characteristic peak of benzene ...

Embodiment 2

[0038] A kind of halogen-free intumescent flame-retardant ABS resin comprises the following components by weight percentage:

[0039]

[0040] The antioxidant is a compound of antioxidant 168 and antioxidant 1076, and its mass ratio is 1:1.

[0041] A preparation method of halogen-free intumescent flame-retardant ABS resin, comprising the following steps:

[0042] (1) Each material was weighed according to the above weight percentage, and dried in a blast oven at 80° C. for 4 hours.

[0043] (2) Mix CEPPAME and OMMT in a high-speed mixer for two minutes to obtain Mixture I.

[0044] (3) Put the mixture I, ABS resin, antioxidant, and white mineral oil into a high-speed mixer and mix again for two minutes to obtain mixture II.

[0045] (4) Adjust the speed of the main engine of the twin-screw extruder to 50r / min, the temperature of the first stage: 185°C, the temperature of the second stage: 190°C, the temperature of the third stage: 190°C, the temperature of the fourth stage...

Embodiment 3

[0047] A kind of halogen-free intumescent flame-retardant ABS resin comprises the following components by weight percentage:

[0048]

[0049]

[0050] The antioxidant is a compound of antioxidant 168 and antioxidant 1076, and its mass ratio is 1:1.

[0051] The preparation method of the above-mentioned halogen-free intumescent flame-retardant ABS resin is the same as that in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com