Hybridization catalyst for curing cyanate ester and preparing method thereof

A kind of technology of cyanate ester and catalyst, applied in graphene oxide-manganese-based metal-organic framework hybrid material and preparation field thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 1.1g of potassium hydroxide, 0.68g of imidazole, 2.64g of 4,4’-dicarboxydiphenyl ether and 0.18g of graphene oxide into 70mL of deionized water, and ultrasonically disperse at 60°C for 30min to obtain solution A.

[0031] Solution B was obtained by dissolving 2.45 g of manganese acetate tetrahydrate in 10 mL of deionized water.

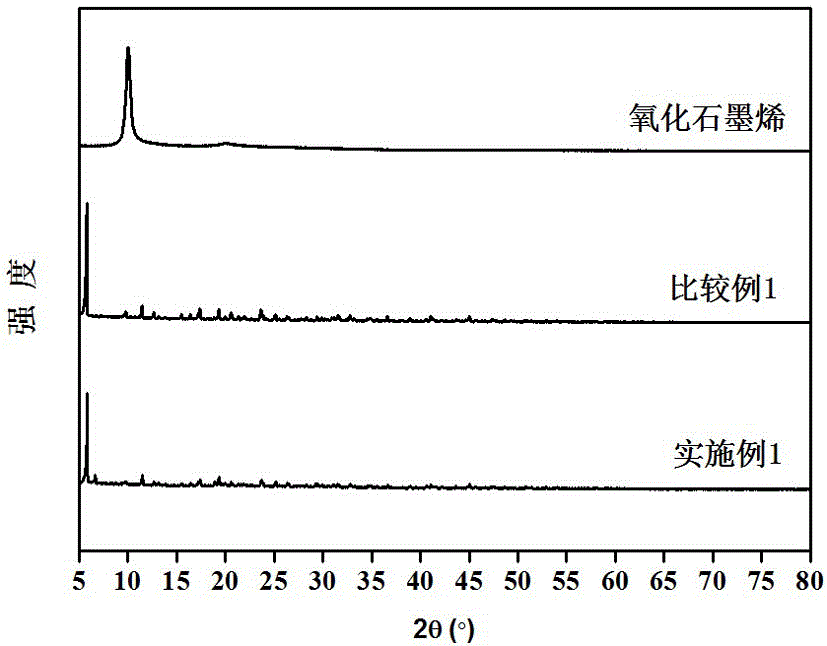

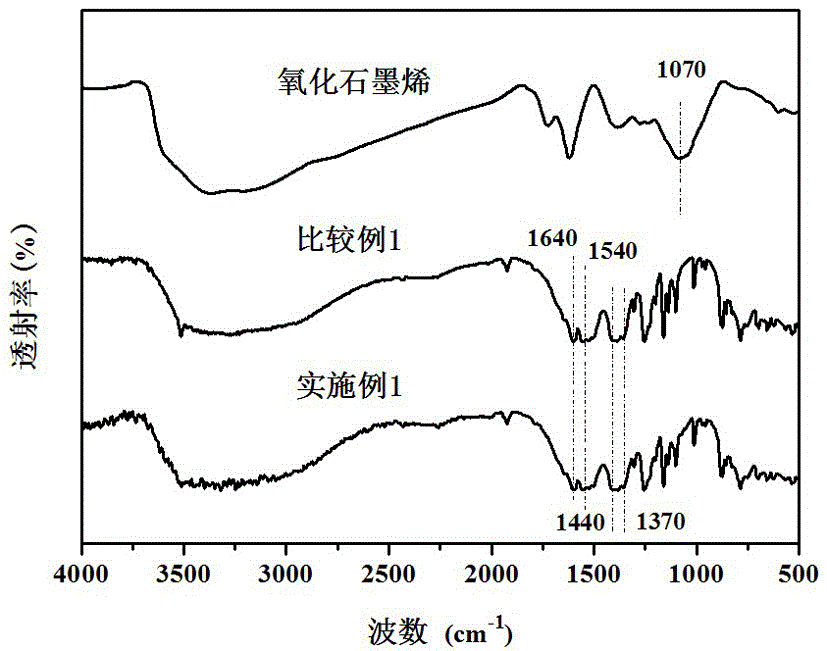

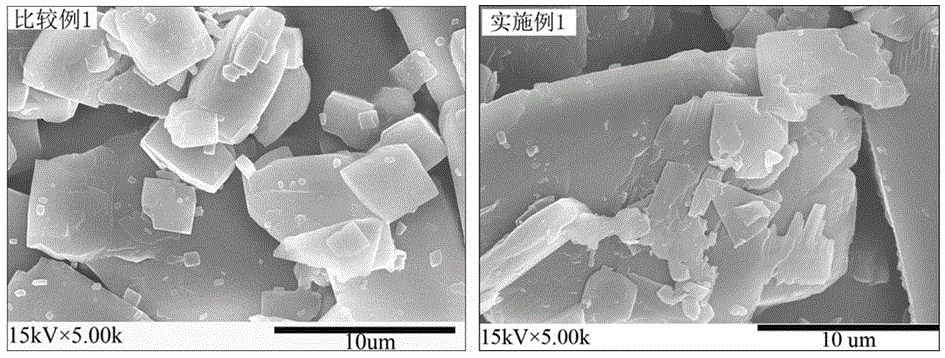

[0032] Add solution A dropwise to solution B, stir and react at 75°C for 24 hours, filter, wash and dry to obtain a graphene oxide-manganese-based metal-organic framework hybrid catalyst, in which graphene oxide and manganese-based metal-organic framework The mass fractions of framework materials are 5wt% and 95wt%, respectively. The X-ray diffraction figure of this catalyst, the infrared spectrum figure, the scanning electron microscope figure of magnification 5,000 times refer to appendix respectively figure 1 , 2 and 3.

Embodiment 2

[0064] Add 1.1g of potassium hydroxide, 0.66g of 2-methylimidazole, 2.53g of 4,4'-dicarboxydiphenyl ether, and 0.034g of graphene oxide into 65mL of deionized water, and ultrasonically disperse at 60°C for 33 minutes to obtain solution A ;Dissolve 2.46g manganese acetate tetrahydrate in 15mL deionized water to obtain solution B; then add solution A dropwise to solution B, stir and react at 80°C for 20h, filter with suction, wash, and dry to obtain oxidized Graphene-manganese-based metal-organic framework hybrid catalyst, wherein the mass fractions of graphene oxide and manganese-based metal-organic framework materials are 1wt% and 99wt%, respectively.

Embodiment 3

[0066] Add 1.1g of potassium hydroxide, 0.69g of imidazole, 2.55g of 4,4'-dicarboxydiphenyl ether, and 0.15g of graphene oxide into 75mL of deionized water, and ultrasonically disperse at 58°C for 35 minutes to obtain solution A; Dissolve manganese acetate tetrahydrate in 5mL deionized water to obtain solution B; then add solution A dropwise to solution B, stir and react at 74°C for 25h, filter with suction, wash, and dry to obtain graphene oxide-manganese Based metal-organic framework hybrid catalyst, wherein the mass fractions of graphene oxide and manganese-based metal-organic framework materials are 4wt% and 96wt%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com