Catalyst with double wrapping structures and preparation method and application of catalyst

A catalyst and double-coated technology, applied in the field of catalysts with double-coated structure and their preparation, can solve the problem of not reaching the performance of precious metal catalysts, and achieve the effects of increasing limit current density, improving catalytic activity, and improving oxygen reduction performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

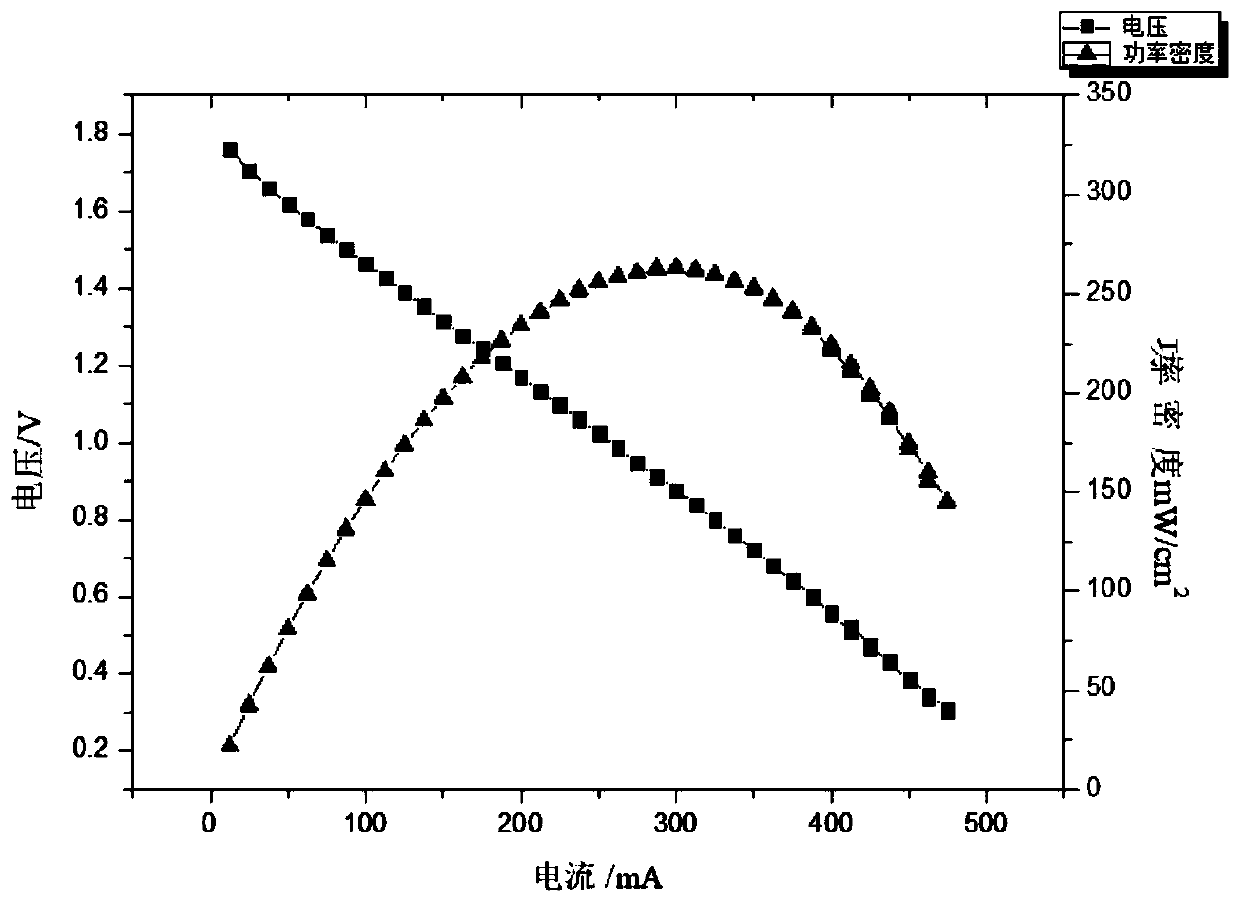

Embodiment 1

[0056] (1) Weigh 12g of nickel nitrate and 28g of cobalt nitrate, add ethanol, magnetically stir for 1-2h, then ultrasonically disperse for 1-2h, transfer to a high-pressure reactor, react at 180°C for 3h, cool, filter, dry, 400 Calcined at ℃ to obtain nickel cobaltate spinel; disperse 16g of nickel cobaltate spinel, 5g of manganese dioxide, and 1.0g of inducer polyethylene oxide in the solvent, stir magnetically for 2h, then ultrasonically disperse for 2h, and dry in an oven at 80°C for 6h , calcined at 500°C to obtain manganese dioxide-coated nickel cobaltate spinel; 20 g of manganese dioxide-coated nickel cobaltate spinel, 4.0 g of graphene, added ethanol to disperse, and added surfactant as dodecyl 1.0 g of sodium benzenesulfonate was dispersed ultrasonically for 10 h, quickly dried under reduced pressure, and vacuum calcined at 700° C. to obtain a double-coated catalyst.

[0057] (2) According to the mass ratio of catalyzer, conductive agent, binding agent and solvent is ...

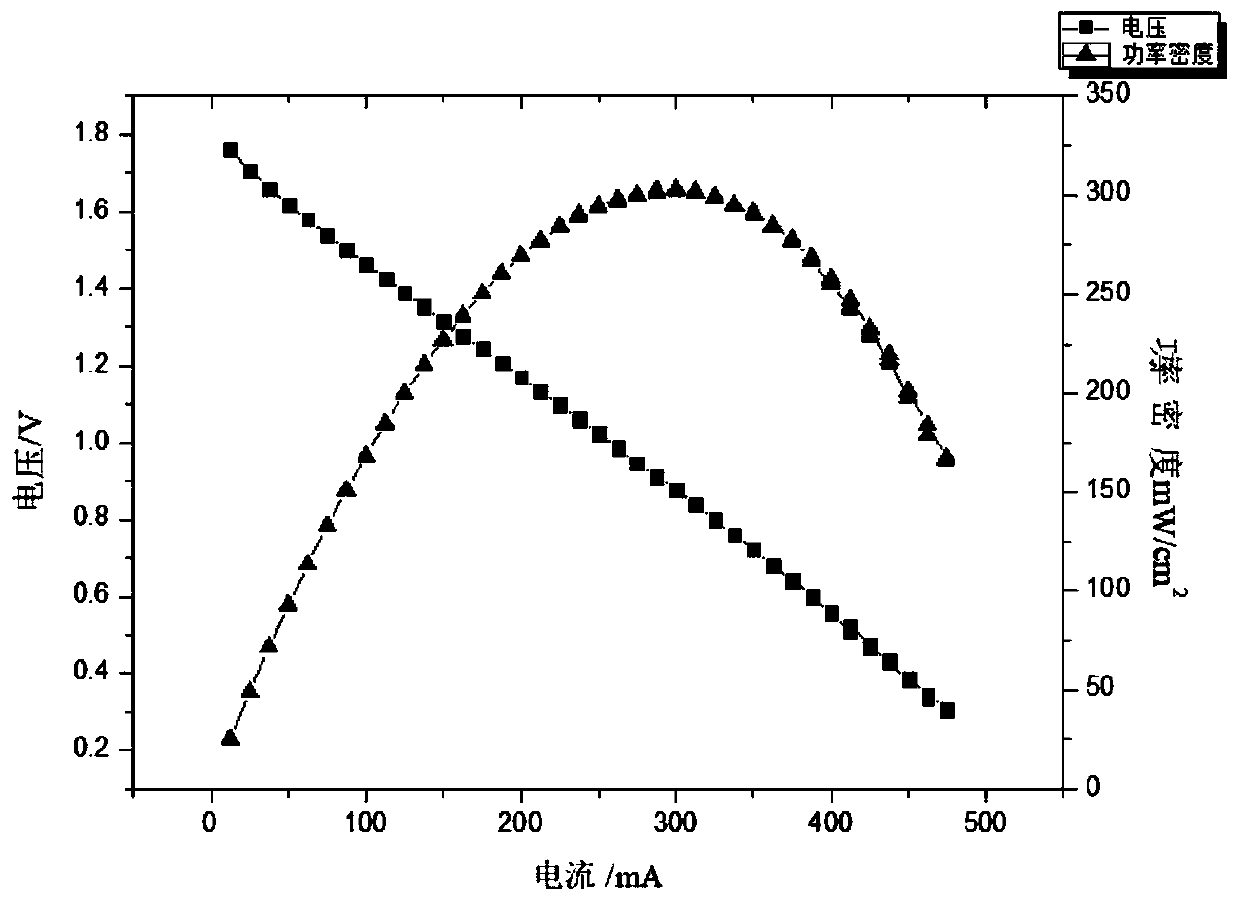

Embodiment 2

[0060] (1) Weigh 12g of nickel nitrate and 27g of cobalt nitrate, add ethanol, stir magnetically for 1-2h, then ultrasonically disperse for 1-2h, transfer to a high-pressure reactor, react at 150°C for 2h, cool, filter, dry, 600 Calcined at ℃ to obtain nickel cobaltate spinel; disperse 15g of nickel cobaltate spinel, 5g of manganese dioxide, and 1.0g of inducer polyvinylpyrrolidone in the solvent, stir magnetically for 2h, then ultrasonically disperse for 2h, 80 Oven-dried at ℃ for 4 hours, calcined at 500℃ to obtain manganese dioxide-coated nickel cobaltate spinel; 18g of manganese dioxide-coated nickel cobaltate, 4.5g of graphene, added ethanol to disperse, and added surfactant dioctylsuccinate Sodium acid sulfonate 1.0 g, ultrasonically dispersed for 12 h, quickly dried under reduced pressure, and calcined at 600° C. to obtain a double-coated catalyst.

[0061] (2) According to the mass ratio of catalyzer, conductive agent, binding agent and solvent is 6.5%: 9.8%: 12.2%: 71...

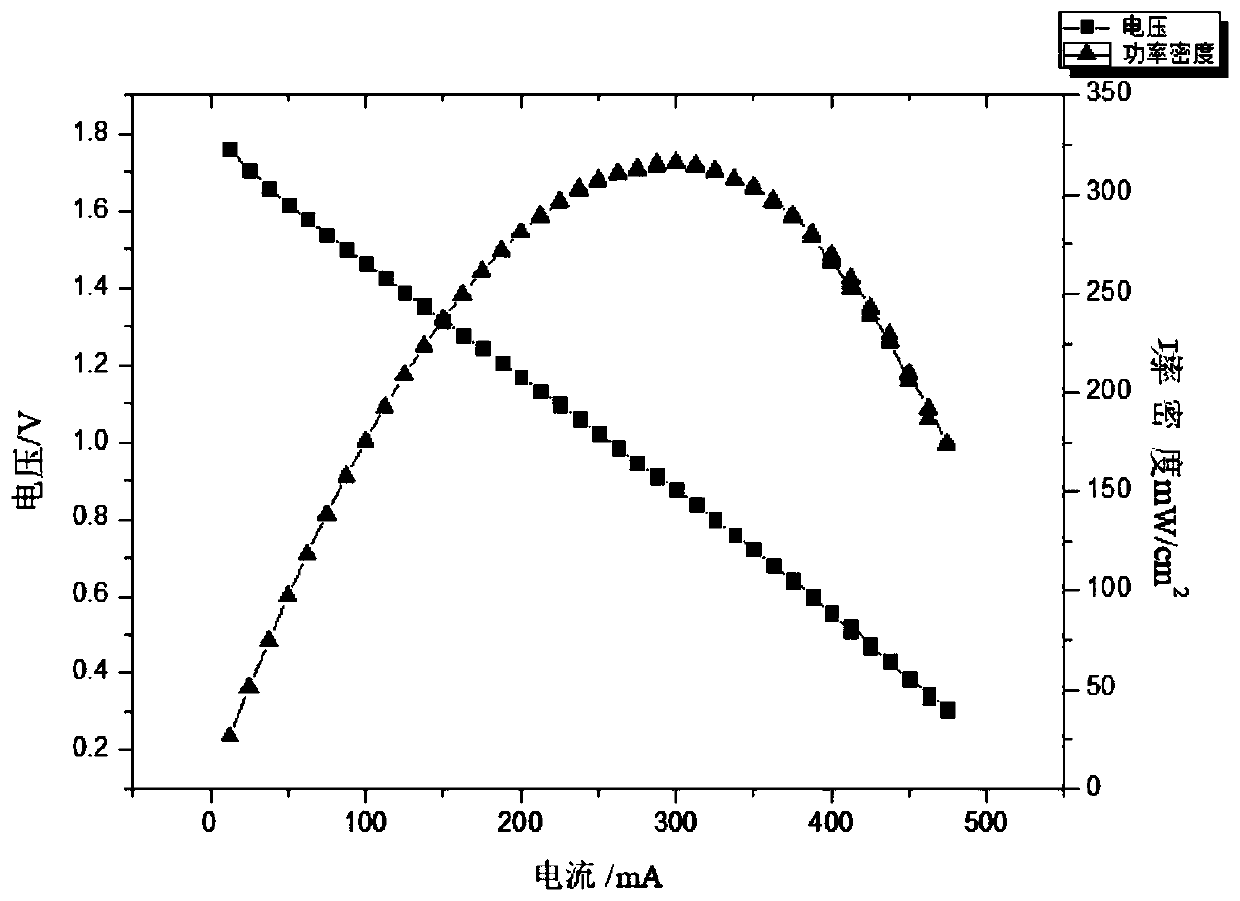

Embodiment 3

[0064] (1) Weigh 13g of nickel nitrate and 26g of cobalt nitrate, add ethanol, stir magnetically for 1-2h, then ultrasonically disperse for 1-2h, transfer to autoclave, react at 110°C for 1h, cool, filter, dry, 400 Calcined at ℃ to obtain nickel cobaltate spinel; disperse 25g of nickel cobaltate spinel, 6g of manganese dioxide, and 1.0g of inducer polyethylene oxide in the solvent, magnetically stir for 1h, then ultrasonically disperse for 1h, and dry in an oven at 80°C for 5h , calcined at 500°C to obtain manganese dioxide-coated nickel cobaltate spinel; manganese dioxide-coated nickel cobaltate 28g, carbon nanotubes 5.0g, added ethanol to disperse, added surfactant sulfated castor oil 1.0g, Then ultrasonically disperse for 6 h, quickly dry under reduced pressure, and calcined at 800° C. to obtain a double-coated catalyst.

[0065] (2) According to the mass ratio of catalyzer, conductive agent, binding agent and solvent is 6.5%: 9.8%: 12.2%: 71.5%, take by weighing above-ment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com