3-D shoulder joint prosthesis

A shoulder joint and prosthesis technology, applied in the field of artificial shoulder joint prosthesis, can solve the problems of inability to readjust the parameters of the prosthesis, scrap the prosthesis, increase the incidence of postoperative complications, etc. Large adjustment range, stable and reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

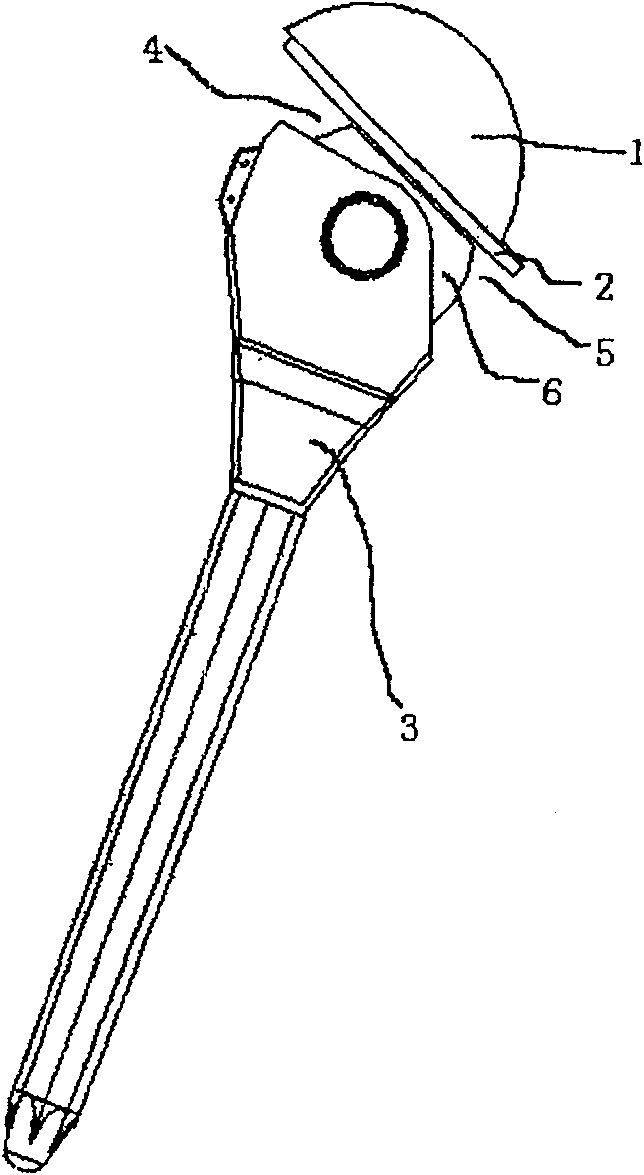

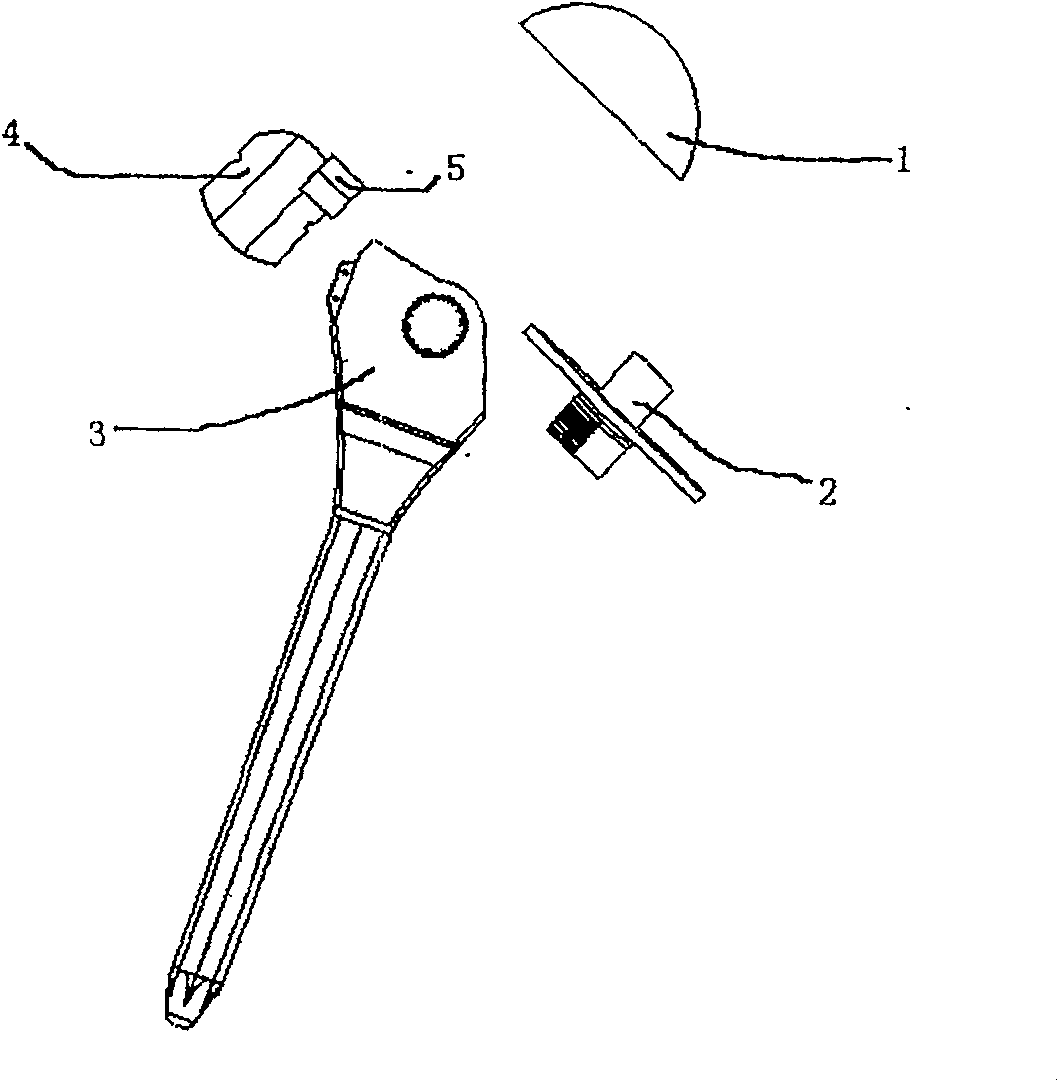

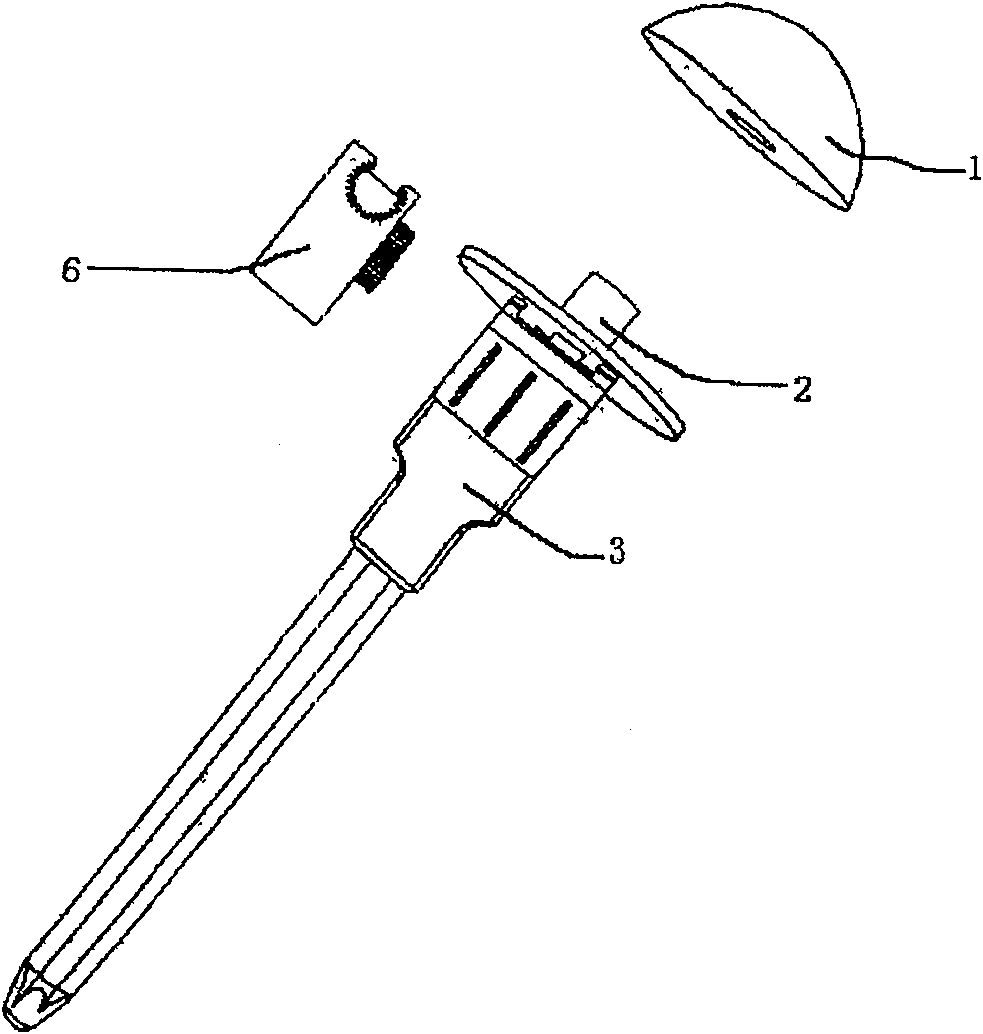

[0035] Below in conjunction with accompanying drawing, the present invention is further described as follows:

[0036] The present invention is made up of spherical crown body 1, handle 3, inclination part (strip wedge block 4 and fan-shaped block 6), torsion part (circular plate 2 and cylindrical block 5), and its operation process is specifically as follows: remove patient's humeral head Drill a cavity corresponding to the shape of the rod 9 of the handle 3 in the humerus of the patient, implant the handle 3 of the shoulder joint, put the fan-shaped block 6, and let the fan-shaped block 6 follow the smooth arc transition area of the head of the handle 3 Rotate to adjust the inclination of the proximal humeral articular surface, and push the fan-shaped block 6 toward the direction of the inner-toothed through-hole after the adjustment is appropriate, so that the outer-toothed boss 23 on the fan-shaped block 6 completely enters the inner-toothed through-hole 7 of the handle 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com