Continuative energy regulation control method of single-screw compressor

A single-screw compressor, energy regulation technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of poor adaptability and difficulty, and achieve the effect of small overshoot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

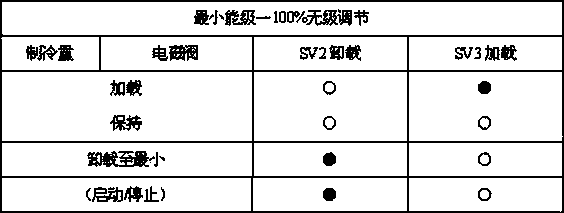

[0015] Embodiment 1, the present invention provides a single-screw compressor stepless energy regulation control method, which includes the following steps: first adopt fuzzy control, divide the temperature control zone into a loading zone, a holding zone, and an unloading zone, and take the temperature control cycle as Unit, to judge which area the temperature is in, and decide whether to load or unload according to the area where it is located. The loading or unloading speed is calculated by the temperature difference control method. The pulse interval time is used to realize the adjustable loading / unloading speed. The loading / unloading pulse time remains unchanged. The smaller the loading / loading pulse interval time, the faster the speed. The algorithm of the temperature difference control method is: output loading pulse interval = maximum loading Interval - [ (current temperature - set temperature - control temperature difference) × (maximum loading interval - minimum loadi...

Embodiment 2

[0016] Embodiment 2, the present invention provides a stepless energy regulation control method for a single screw compressor, which includes the following steps: first adopt fuzzy control, divide the temperature control zone into a loading zone, a holding zone, and an unloading zone, and take the temperature control cycle as The unit judges which area the temperature is in, and decides whether to load or unload according to the area where it is located. The loading or unloading speed is calculated using the PID control method. To adjust the energy level to meet the requirements of the outlet water temperature, the algorithm of the PID control method is:

[0017] Number of output loading and unloading pulses = A×e(3)-B×e(2)+C×e(1);

[0018] Where A=proportional gain×(1+sampling period / integration time+differential time / sampling period);

[0019] B=proportional gain×(1+2×differential time / sampling period);

[0020] C=proportional gain×differential time / sampling period;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com