Ultrasonic Doppler flow direction and flow rate instrument

A flow meter and ultrasonic technology, applied in the field of ultrasonic Doppler flow direction flow meter, can solve the problems of affecting the measurement accuracy, being unable to measure, destroying the natural flow field pattern, etc., achieving accurate sampling data, ensuring measurement accuracy, and convenient and fast measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

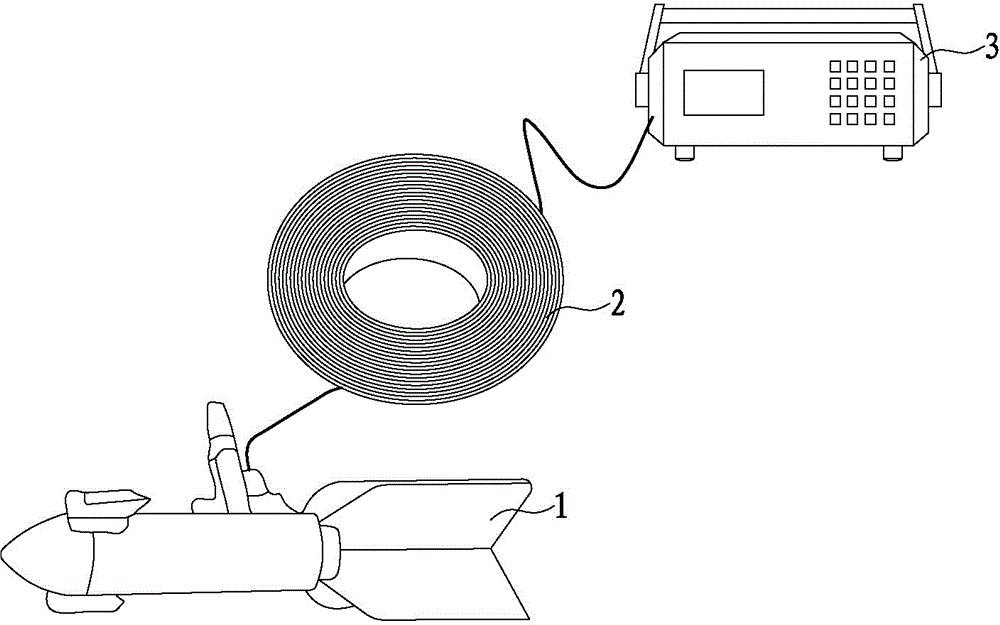

[0022] Such as figure 1 As shown, the present invention is an ultrasonic Doppler flow velocity meter, which is composed of a probe 1, a cable 2, and a water surface host 3.

[0023] The probe 1 is connected with the surface host 3 through the cable 2, and transmits the underwater signal to the surface host 3.

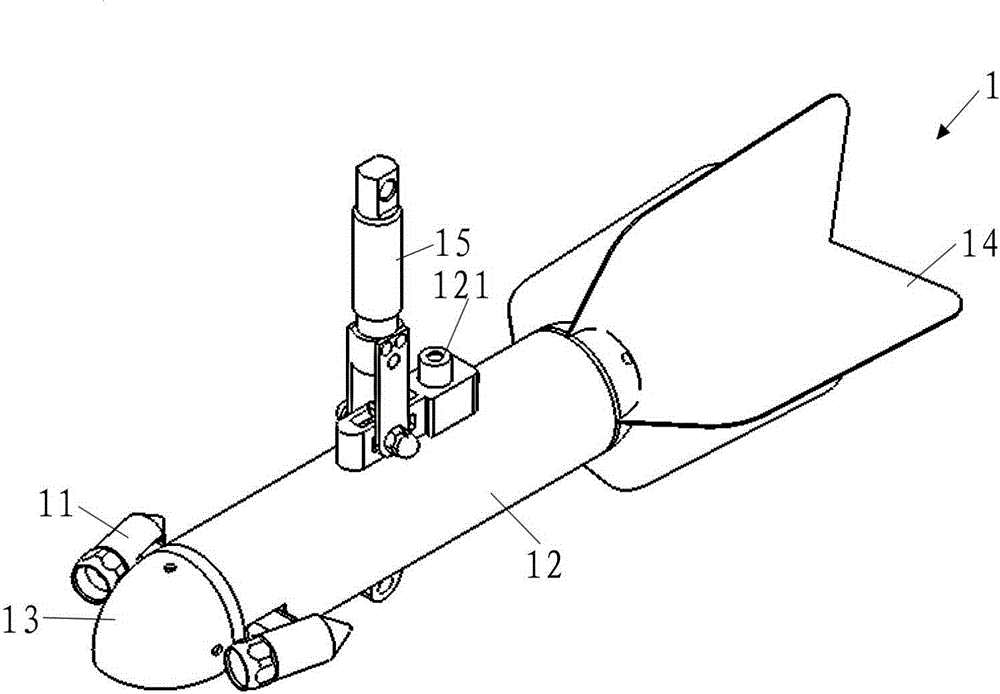

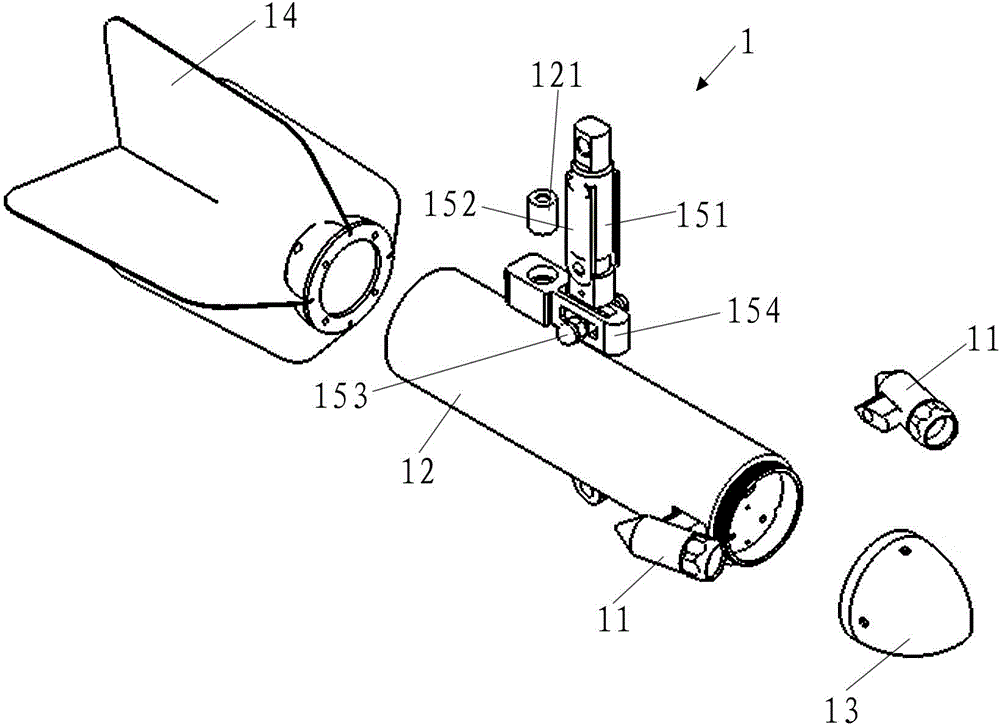

[0024] Such as Figure 2-Figure 7 As shown, the probe 1 includes two transducers 11, a pipe body 12, a diverter head 13, an empennage 14, a rotating rotor connector 15, a circuit board 16, a pressure sensor 17, a temperature sensor 18, and a flow direction sensor 19 , circuit board support 20, lead fish hanging hole 21.

[0025] The rotating rotor connector 15 is composed of a rotating boom 151 , a boom side plate 152 , a balance positioning bolt 153 and a boom seat 154 . The boom seat 154 is fixed on the top surface of the pipe body 12, and the middle part of the boom seat 154 has a horizontal long groove 155; the balance positioning bolt 153 is detachably penetrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com