Flaskless vacuum molding chamber temperature control circuit

A technology of temperature control circuit and box vacuum, which is applied in the direction of temperature control by electric mode, auxiliary controller with auxiliary heating device, etc., which can solve the problems of waste products, sand molds that cannot be hardened normally, and sand mold quality instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

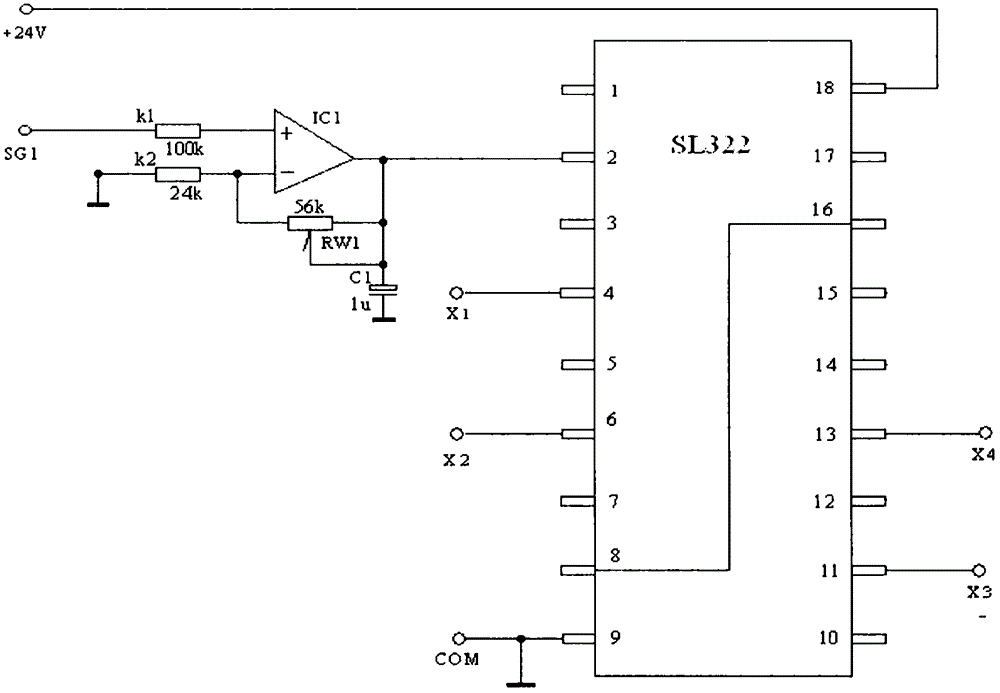

[0009] The safety vacuum chamber control principle of the embodiment of this circuit is: the input terminal SG1 comes from the output terminal of the temperature sensor SH05 (the output voltage is 0~5V between -10~+40°C). Based on the two years of operating experience, we set four operating points of 0°C, 10°C, 20°C, and 30°C, and respectively controlled four groups of working programs to operate at different temperatures within a year.

[0010] The connection relation of the described input signal part circuit is: the positive end of the voltage comparator IC1. that the input terminal SG1 connects LM224 to form, the negative end of the voltage comparator IC1. The negative end of the voltage comparator IC1 connects one end of the resistor K2 and the One end of the potentiometer RW1, the other end of the resistor K2 is grounded; the other two ends of the potentiometer RW1 are connected to the output end of IC1 to form a voltage amplifier IC1. The working principle of the voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com