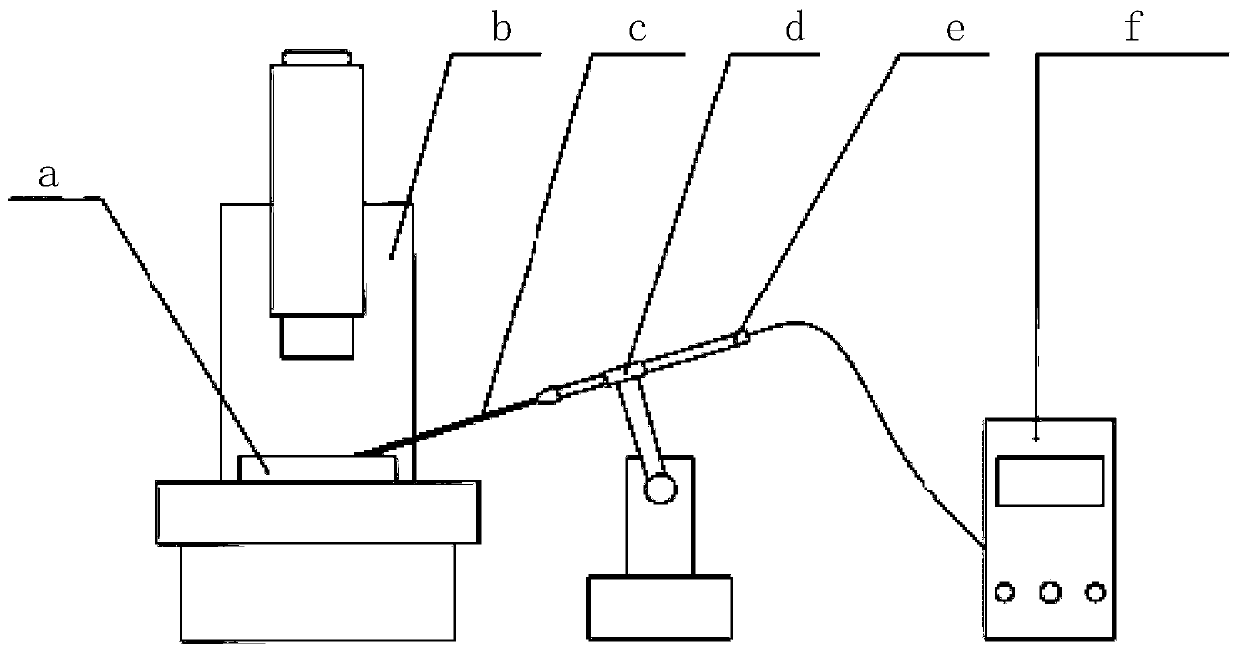

Ultra-micro injection detection and control device and method based on lensless imaging technology

A control device and lens-less technology, which is applied in the direction of using micro-injection method, measuring device, enzymology/microbiology device, etc., can solve the problem of lack of accurate detection of capillary glass needles, etc., and achieve simple structure, low cost, and technical maturity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

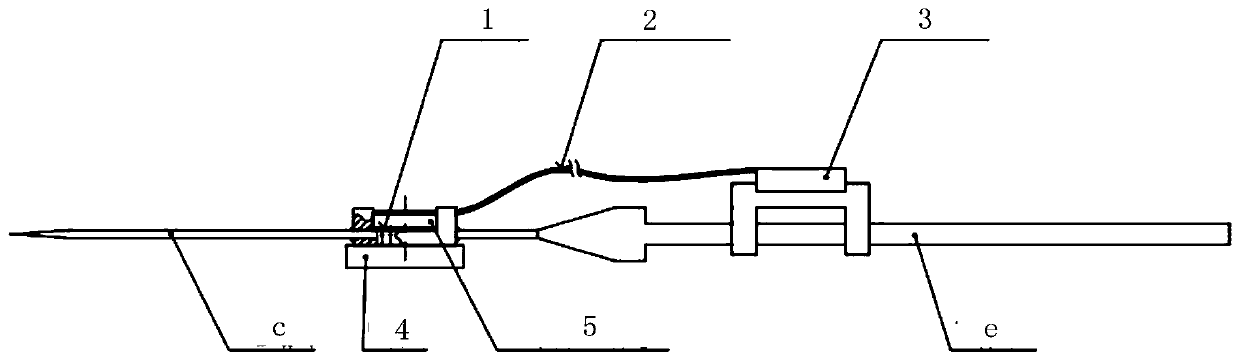

[0046] In the present invention, the miniature line array image sensing chip can be the model S10226 linear CMOS image sensor produced by Hamamatsu as the detection chip, the number of sensing bits is 12 bits, the photosensitive area specification is a single pixel 7×125 μm, and the line array has a total of 1024 pixels , the total length of the photosensitive area is 8mm, and the overall dimensions are 9.1mm×2.4mm×1.6mm. The surface of the sensor is covered with a light-reducing film that reduces light by 90%, and the external light source is composed of LED light-emitting elements and light-guiding fibers, and the light intensity is about 150lux. The glass injection needle can be drawn from a capillary glass tube with an outer diameter of 1 mm and an inner diameter of 0.5 mm. The pneumatic microsyringe pump can be used with the FemtoJet 4i upgrade microsyringe pump produced by Eppendorf.

[0047] In this embodiment, it is assumed that the liquid surface light can saturate t...

specific Embodiment approach 2

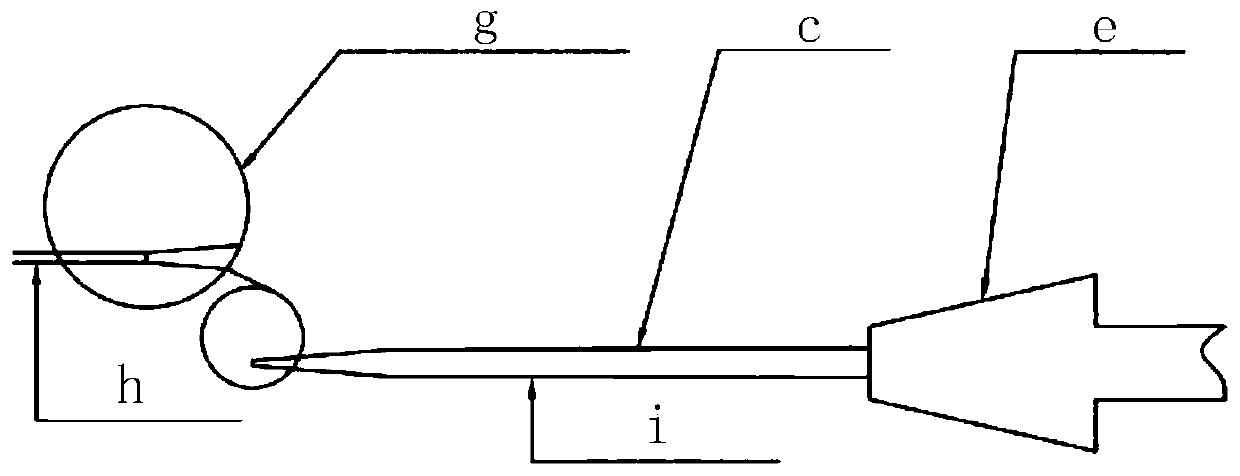

[0053] Specific Embodiment 2: This embodiment is a further description of the ultra-microinjection detection and control device based on lensless imaging technology described in Specific Embodiment 1. In this embodiment, the parallel light source 4 includes LED light-emitting elements, guide The optical fiber and the light-homogeneous film, the LED light-emitting element, the light-guiding fiber and the light-homogeneous film are laminated and arranged sequentially from the outside to the inside.

specific Embodiment approach 3

[0054] Embodiment 3: This embodiment is a further description of the ultra-microinjection detection and control device based on lensless imaging technology described in Embodiment 1. In this embodiment, the control unit includes a drive circuit 3 and a flexible circuit board 2, the driving circuit 3 is arranged on the needle holder e, the driving circuit 3 is connected to the micro linear array image sensing chip 5 through the flexible circuit board 2, and the flexible circuit board 2 is used to collect the measurement information of the micro linear array image sensing chip 5 According to the information, the injection pressure of the injection pump is corrected, and the driving circuit 3 is used to drive the injection pump to work according to the injection pressure sent by the flexible circuit board 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com