Special vertical type picking machine for motor rotor

A technology for motor rotors and pick-up machines, which is applied in the manufacture of stators/rotor bodies, etc., can solve the problems of scalding operators, prolonging the production cycle, and high labor intensity, so as to reduce labor intensity, reduce production costs, and avoid duplication of labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

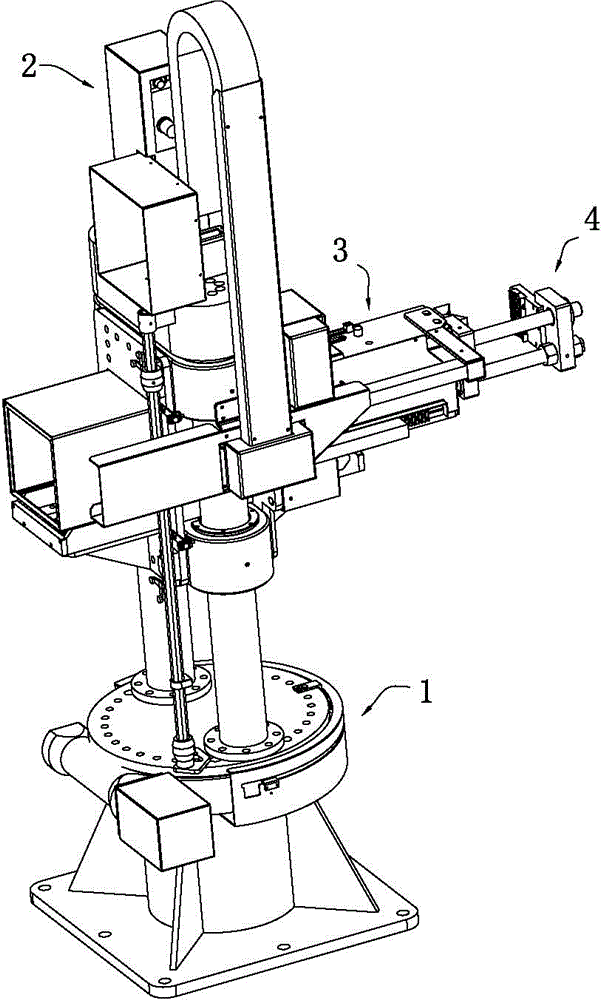

[0023] Examples, see Figure 1 to Figure 3 , a special vertical pick-up machine for motor rotors provided in this embodiment, which includes a rotating base 1, a lifting mechanism 2, a telescopic arm 3 and a gripping mechanism 4, the lifting mechanism 2 is arranged on the rotating base 1, and is subjected to The rotating base 1 is driven to rotate, and one end of the telescopic arm 3 is arranged on the lifting mechanism 2, and the other end is connected with the gripping mechanism 4, and can drive the gripping mechanism 4 to perform telescopic movement.

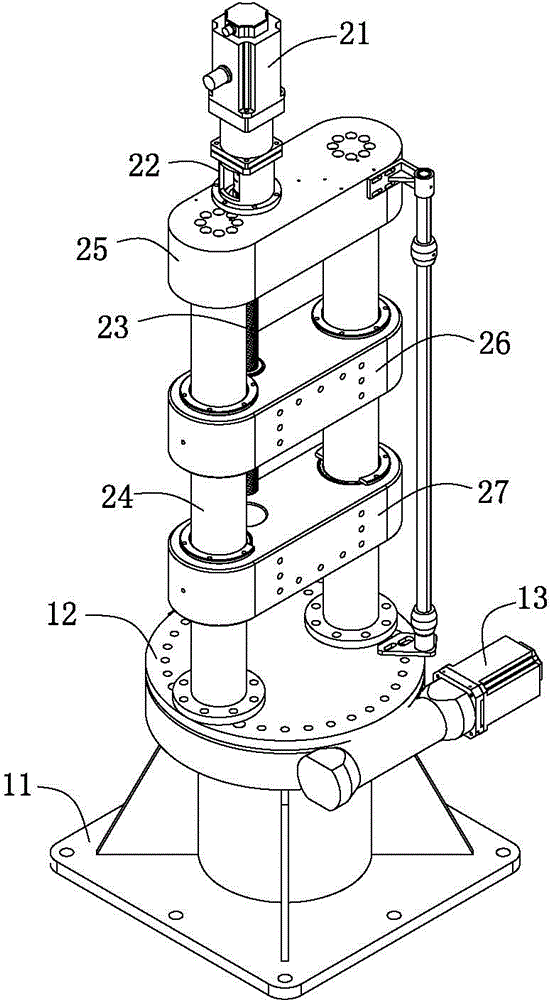

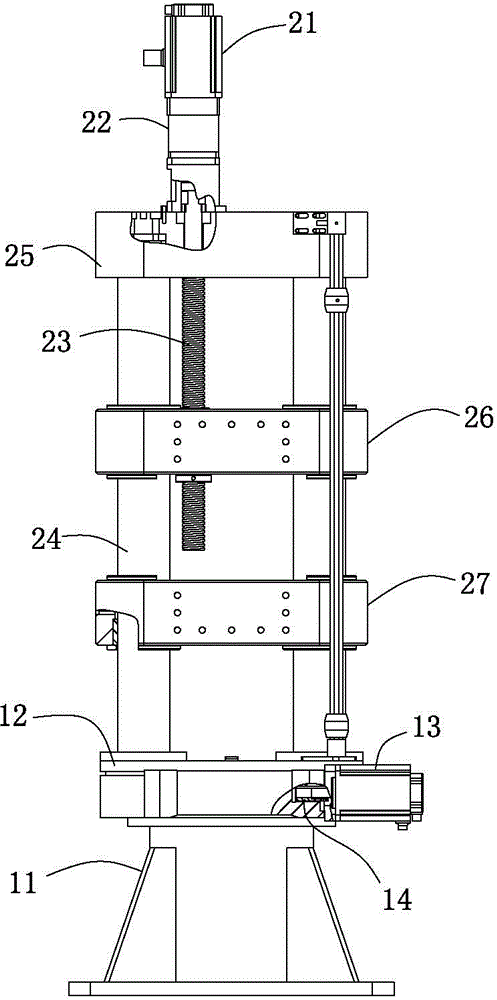

[0024] see figure 2 and image 3 , the rotating base 1 includes a base 11, a turntable 12 and a rotary servo motor 13, the turntable 12 is movably set on the upper surface of the base 11 through a bearing assembly, and the rotary servo motor 13 is set on the base One side of the seat 11, and can drive the turntable 12 to rotate through the gear assembly 14. Specifically, the bottom surface of the turntable 12 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com