A kind of preparation method of soy sauce

A production method and technology of soy sauce, applied in food science and other directions, can solve the problems of high water content, environmental pollution, waste of resources, etc., and achieve the effects of rich sauce, palatable salty and delicious taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

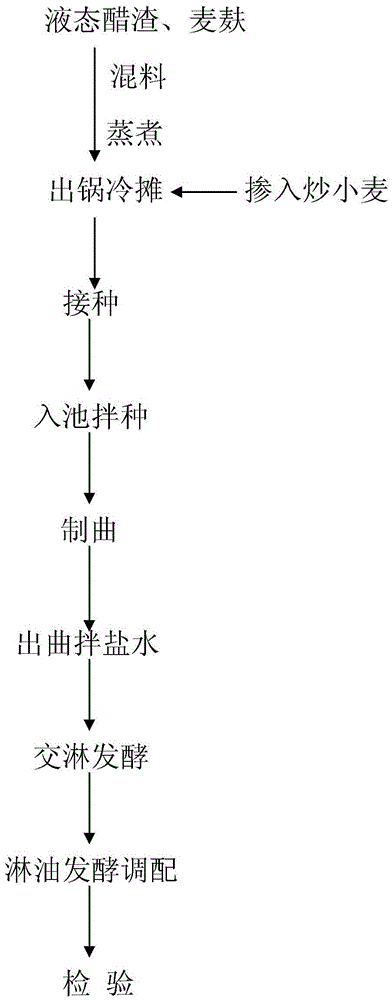

[0026] The soy sauce technology of the present invention is processed by the following method: take 600kg liquid vinegar residue as an example to illustrate.

[0027] 1) Mixing: Feed 600kg of fresh liquid vinegar residue and 200kg of wheat bran into the steaming ball through the elevator, and turn the steaming ball to mix the materials for 40 minutes.

[0028] 2) Steaming material: After the mixing is completed, pass steam to steam the material, exhaust once at 0.05Mpa, once at 0.1Mpa, and maintain at 0.15Mpa for 10 minutes before exhausting.

[0029] 3) Mixed ingredients out of the pot and cold spread: Mix the steamed ingredients with 200kg of crushed fried wheat evenly.

[0030] 4) Inoculation: Take 50kg of cooled material and 550g of koji essence for soy sauce and stir evenly.

[0031] 5) Seed dressing in the pond: Send the cold spread materials to the koji pond, start the blower to keep the temperature of the materials at 33-35 degrees, then mix the seeds into the remaini...

Embodiment 2

[0038] The soy sauce technology of the present invention is processed by the following method: take 600kg liquid vinegar residue as an example to illustrate.

[0039] 1) Mixing: Feed 600kg of fresh liquid vinegar residue and 300kg of wheat bran into the steaming ball through the elevator, and turn the steaming ball to mix the materials for 40 minutes.

[0040] 2) Steaming material: After the mixing is completed, pass steam to steam the material, exhaust once at 0.05Mpa, once at 0.1Mpa, and maintain at 0.15Mpa for 10 minutes before exhausting.

[0041] 3) Mixed ingredients out of the pot and cold spread: Mix the steamed ingredients with 100kg of crushed fried wheat evenly.

[0042] 4) Inoculation: Take 60kg of cooled material and 450g of koji essence for soy sauce and stir evenly.

[0043] 5) Seed dressing in the pond: Send the cold spread materials to the koji pond, start the blower to keep the temperature of the materials at 33-35 degrees, then mix the seeds into the remaini...

Embodiment 3

[0050] The soy sauce technology of the present invention is processed by the following method: take 500kg liquid vinegar residue as an example to illustrate.

[0051] 1) Mixing: Feed 500kg of fresh liquid vinegar residue and 200kg of wheat bran into the steaming ball through the elevator, and turn the steaming ball to mix the materials for 40 minutes.

[0052] 2) Steaming material: After the mixing is completed, pass steam to steam the material, exhaust once at 0.05Mpa, once at 0.1Mpa, and maintain at 0.15Mpa for 10 minutes before exhausting.

[0053] 3) Mixed ingredients out of the pot and cold spread: Mix the steamed ingredients with 300kg of crushed fried wheat evenly.

[0054]4) Inoculation: Take 40kg of cooled material and 400g of koji essence for soy sauce and stir evenly.

[0055] 5) Seed dressing in the pool: send the cold spread material to the koji pool, start the blower to keep the temperature of the material at 33-35 degrees, then mix the seeds into the remaining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com