Preset intraocular lens implanter

A technology of intraocular lens and implanter, applied in intraocular lens, eye implant, ophthalmic surgery, etc., can solve problems such as failure of implantation process, increased operation complexity, complicated operation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

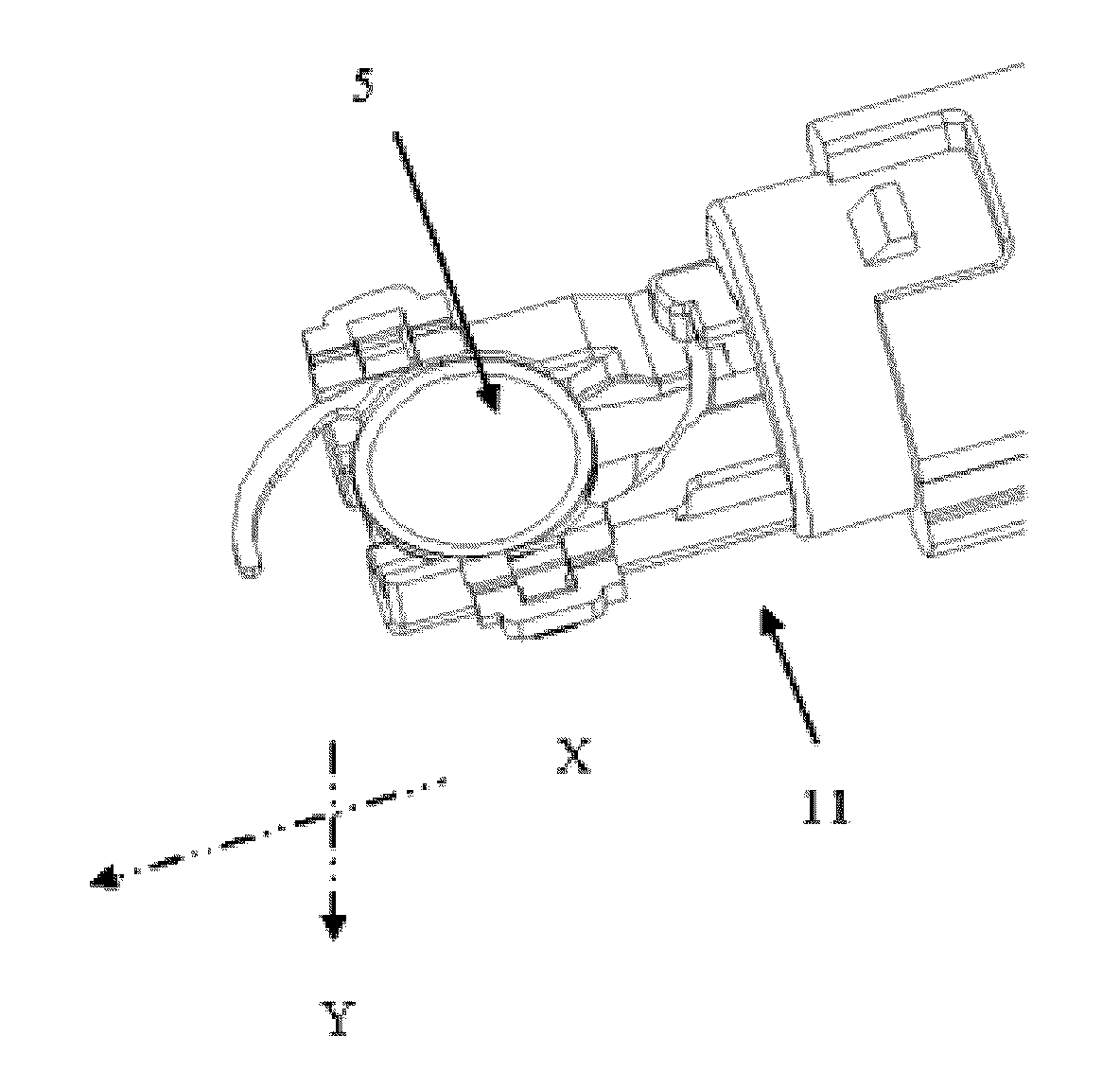

[0076] figure 1 A perspective view schematically showing the overall structure of the preassembled intraocular lens implanter 1 of the present invention. Such as figure 1 As shown in , the preassembled intraocular lens implanter 1 includes: a main body 3 , an implant head 2 that is plugged and fitted with the front end of the main body 3 , and a spiral tube 4 connected with the rear end of the main body 3 . The intraocular lens 5 is pre-placed inside the main body 3, and the intraocular lens 5 has an optical part 6 and a pair of haptics (including anterior haptic 7a and posterior haptic 7b, such as figure 2 shown).

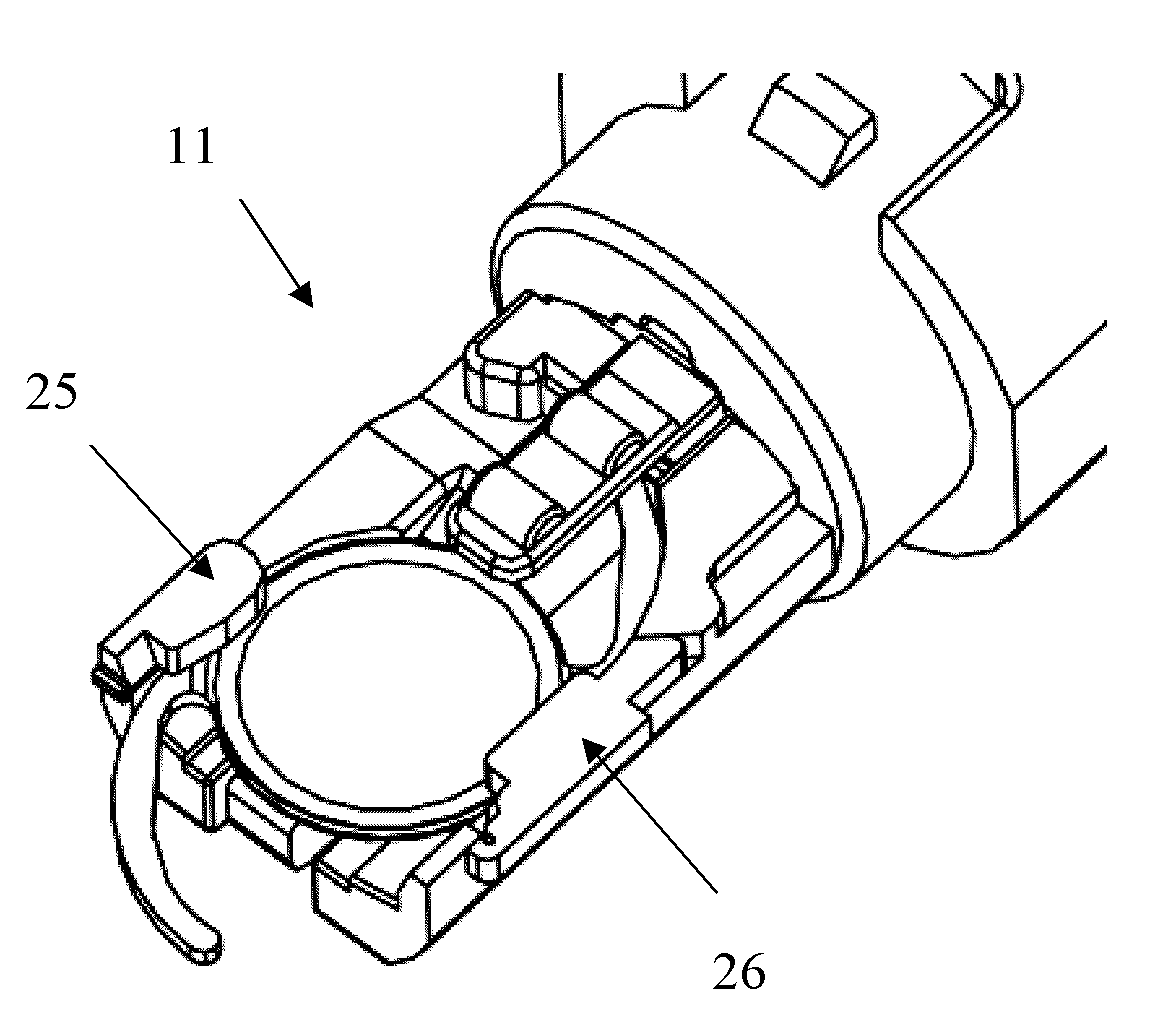

[0077] figure 2The constituent parts of the pre-assembled intraocular lens implanter 1 are clearly shown through an exploded view. The main body 3 includes an intraocular lens bearing part 11 at its front end and a main body rear end 12 connected with the spiral tube 4 . The intraocular lens 5 is pre-placed on the intraocular lens bearing part 11 at the fro...

no. 2 approach

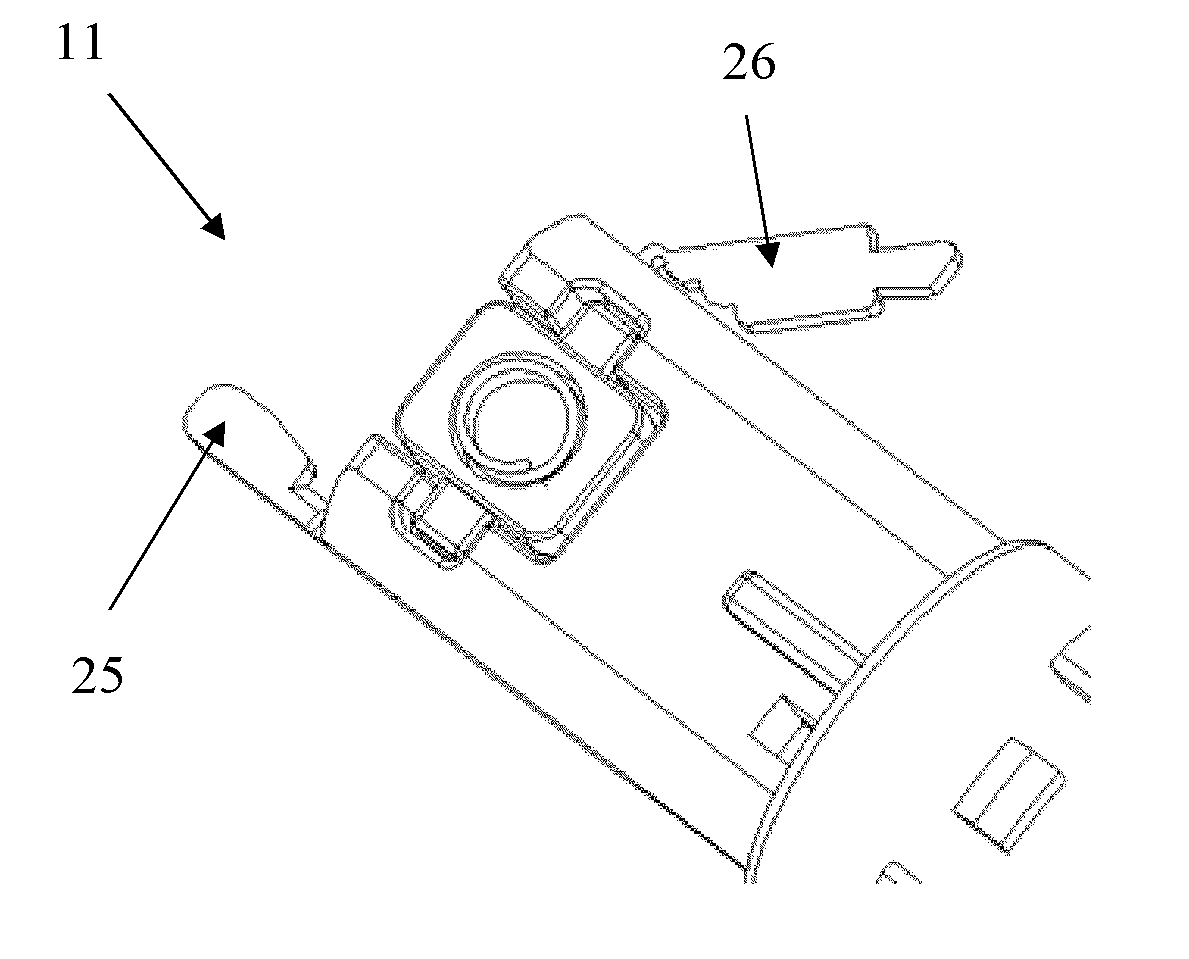

[0084] The carrying elastic piece 16 can also be a separate component. Figure 14a and Figure 14b It is an assembly perspective view schematically showing that the carrying elastic piece 16 and the IOL carrying part 11 at the front end of the main body are two separate parts connected together by snap-fitting. It can be seen from the figure that the limiting pressing piece 21, as a separate component, is connected with the IOL bearing part 11 at the front end of the main body through the buckle at the rear end. Figure 14b The sectional view shows the connection relationship between the split bearing elastic piece 21 and the artificial lens bearing part 11 at the front end of the main body.

[0085] Figure 17 is a schematic perspective view schematically showing the folding limiting sheet 15 according to the second embodiment of the present invention, wherein the intraocular lens is not loaded. Figure 17a is schematically shown Figure 17 Front projection of folded stop...

no. 3 approach

[0091] Figure 15 , Figure 16 Front and rear assembled views of an axial bearing block according to a third embodiment of the invention are shown.

[0092] From Figure 16 It can be seen more clearly that the assembly parts of the axial bearing block are composed of a split bearing block 22 and a spring 23, and the spring 23 is assembled in the hole of the split bearing block 22, so that the axial bearing block 22 can be mounted on the spring. Under the action, it moves along the Y-axis direction, and the guide protrusion 22a on the axial bearing block 22 is assembled in the bearing block guide groove 24 on the back of the IOL bearing part at the front end of the main body, so that the position of the axial bearing block 22 in the X-axis direction is constrained fixed. The structure here can also realize the function of carrying the elastic piece 16 as described in the aforementioned first and second embodiments.

[0093] 4. Fourth Embodiment

[0094] Figure 23a and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com