Roll gap calibration method for lightly pressing down tension leveler in square billet continuous casting

A billet continuous casting and calibration method technology, applied in the field of roll gap calibration of tension levelers, can solve the problems of large calibration error, lack of technical solutions, low precision, etc., to improve roll gap control accuracy, save calibration time, and improve The effect of calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

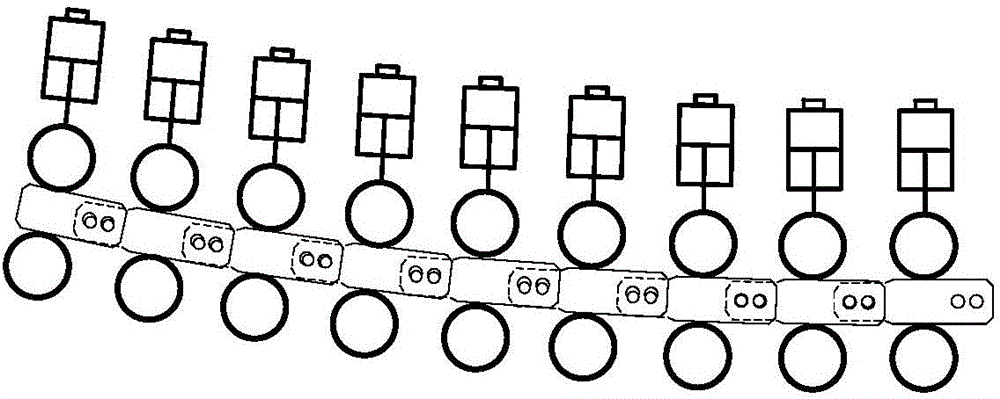

[0087] Number of tensioning and leveling machines: 9 sets, distance between tensioning and leveling machines: 1.1m

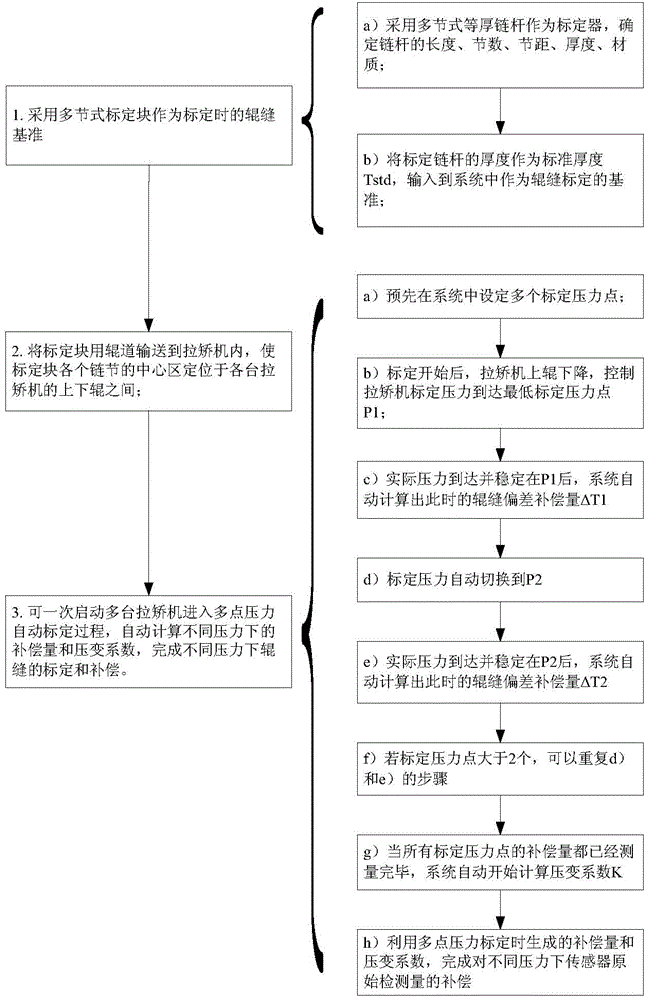

[0088] (1) Using a multi-section chain rod calibrator

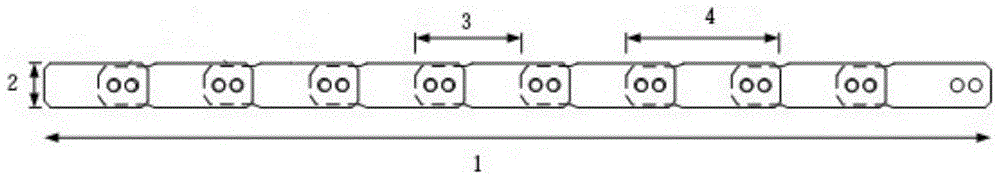

[0089] Calibrator chain link number: 9 sections;

[0090] Total length of calibrator chain rod: 10.3m

[0091] Calibrator chain rod thickness: 320mm;

[0092] Calibrator chain rod pitch: 1.1m;

[0093] Calibrator chain rod material: 40GrMo4;

[0094] System preset standard thickness T std =320mm;

[0095] (2) Transport the calibrator to the tension leveling machine with a roller table, so that the central area of each chain link of the calibrator is positioned between the upper and lower rollers of each tension leveler;

[0096] (3) After the positioning of the calibrator is completed, start 9 tension and straightening machines at a time to enter the multi-point pressure automatic calibration process;

[0097] a) Calibration pressure point: P 1 =10 tons, P 2 =110 tons;

[0098] b) After the cali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com