Fireproof color steel plate

A technology of color steel plate and fireproof layer, which is applied in the direction of building components, layered products, metal layered products, etc., can solve the problems of no flame retardant function, poor rigidity of the steel plate, and fire, so as to prolong the service life and flame retardant Performance enhancement, effect of increased scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

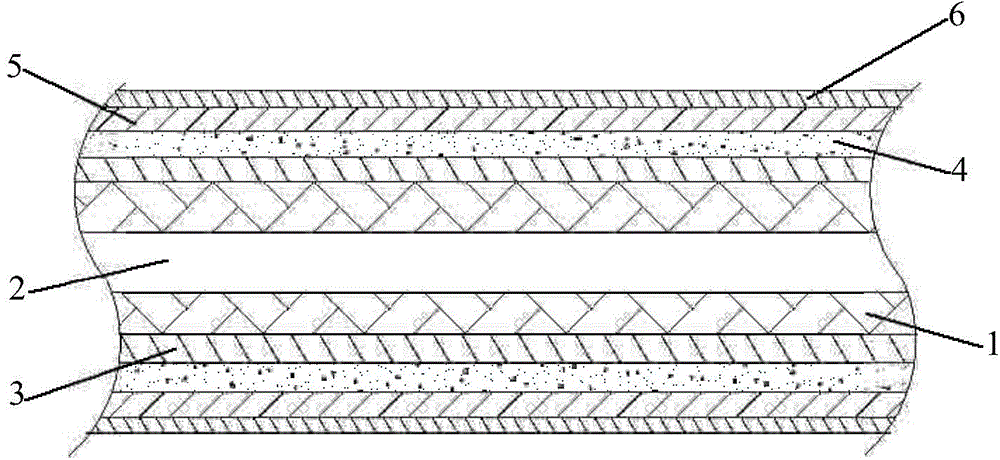

[0012] A specific embodiment of the present invention will be described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the present invention provides a fire-resistant color steel plate, which includes a color steel plate body 1, an insulation layer 2 is arranged between the color steel plate body 1, a PET film 3 is provided outside the color steel plate body 1, and a PET film 3 is provided outside the color steel plate body 1. A heat insulating layer 4 is provided, and a fireproof layer 5 is arranged outside the heat insulating layer 4, and a UV protective layer 6 is arranged outside the fireproof layer 5, the base layer of the color steel plate body 1 is a cold-rolled steel plate, and the PET film 3 and The heat insulating layer 4 is bonded, and the heat insulating layer 4 is bonded to the fireproof layer 5 .

[0014] An example of the present invention has been described in detail above, but the content described is only a preferred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com