Nitrogen content control method for FB2 steel smelted by vacuum induction furnace

A technology of vacuum induction furnace and control method, applied in the direction of furnace, electric furnace, furnace type, etc., can solve the problem of inaccurate control of nitrogen content, achieve the effect of reducing hydrogen content, increasing solubility and surface adsorption, and increasing nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

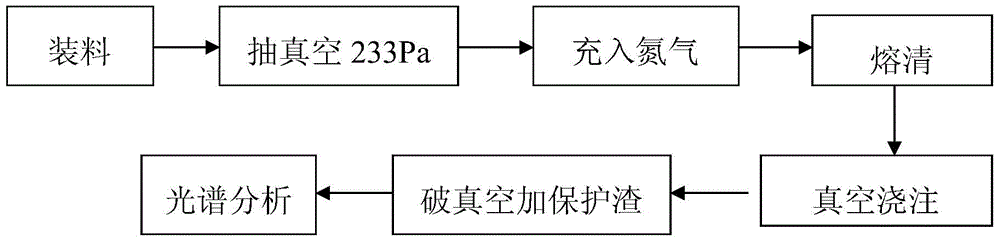

[0024] Such as figure 1 As shown, the nitrogen content control method of the vacuum induction furnace smelting FB2 steel of the present invention controls the nitrogen content in the steel by increasing the nitrogen partial pressure, comprising the following steps:

[0025] The first step, loading;

[0026] Load the solid alloy steel raw material into the vacuum induction furnace;

[0027] The second step is to vacuum;

[0028] Vacuumize the vacuum induction furnace to make the vacuum degree of the furnace chamber below 233Pa;

[0029] After the vacuum degree of the furnace chamber reaches below 233Pa, maintain the vacuum degree in the furnace for 10-12 minutes, and then proceed to the next step;

[0030] The third step is to fill with nitrogen;

[0031] Fill nitrogen into the vacuum induction furnace with a vacuum degree below 233Pa, so that the nitrogen pressure in the vacuum induction furnace is not less than 30KPa;

[0032] The fourth step, melting;

[0033] The vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com