Anti-radiation, reflection and flame-retardation artificial leather

A kind of artificial leather and anti-radiation technology, applied in the field of artificial leather, can solve the problems of slow loss of flame retardancy, single function, easy to cause harm to human body, etc., and achieve the effect of soft and comfortable base layer and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

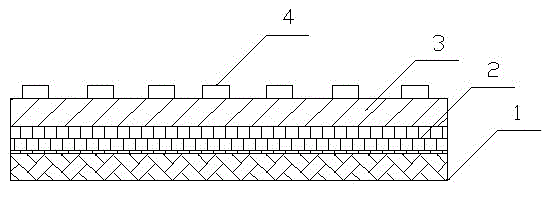

[0014] see figure 1 , the present invention relates to a kind of anti-radiation reflective flame-retardant artificial leather, it comprises the base layer 1 and the surface layer 2 that are mutually bonded together, and the surface layer 2 is provided with the metal fiber layer 3, is arranged on the metal fiber layer 3 There are multiple reflective strips 4, and the material of the reflective strips 4 is high refraction glass beads.

[0015] The base layer is made of fabric, and the fabric is formed by interweaving warp yarns and weft yarns, the warp yarns are made of cotton yarns, and the weft yarns are made of flame-retardant polyester filament yarns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com