Waterproof and breathable fabric for sportswear

A waterproof and breathable, waterproof and breathable membrane technology, applied in clothing, applications, clothing and other directions, can solve the problems of lack of waterproof function, affecting wearing experience, lack of breathability, etc., to achieve good moisture absorption and breathability, inhibit bacterial growth, and improve affinity skin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

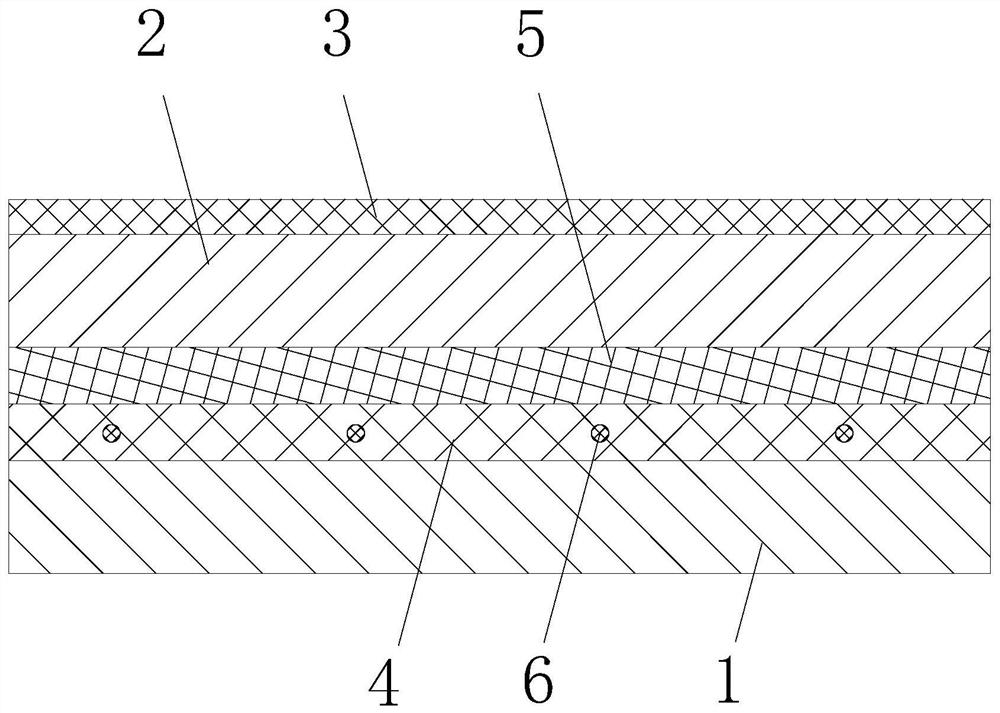

[0023] see Figure 1-2 , the present invention provides a technical solution: a waterproof and breathable fabric for sportswear, comprising a first base layer 1 and a second base layer 2, the upper end surface of the second base layer 2 is covered with a waterproof breathable membrane 3, the first base layer Between the base layer 1 and the second base layer 2, an antibacterial layer 4 and a reinforcing layer 5 are sequentially arranged from bottom to top.

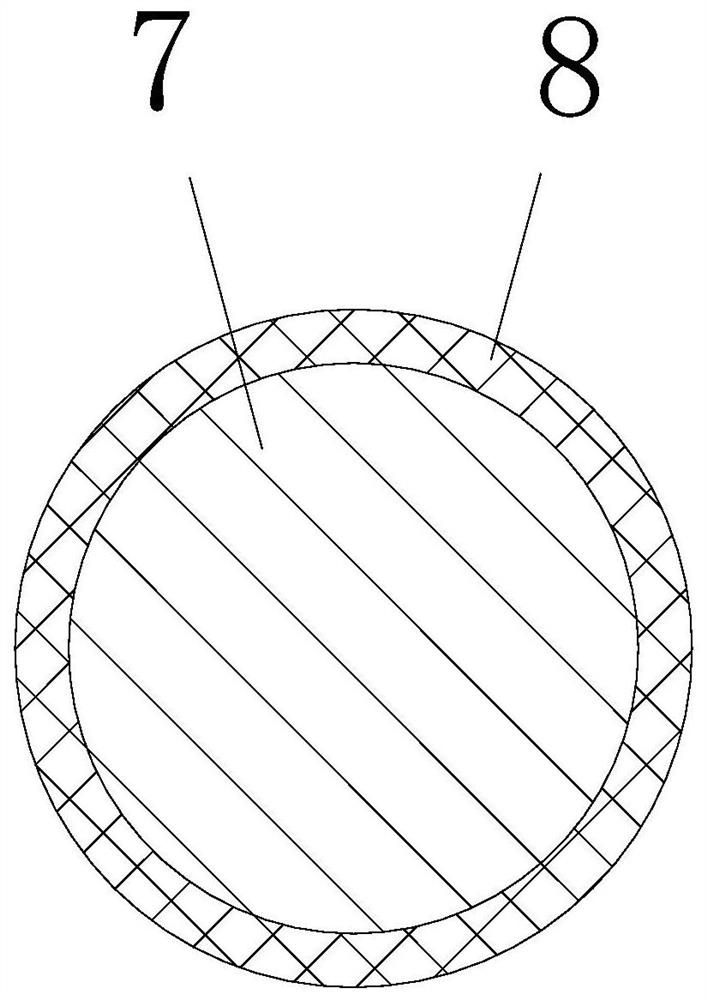

[0024] The first base layer 1 is woven from cotton fibers 7, the bottom end surface of the first base layer 1 is covered with a fluff layer, the outer periphery of the cotton fibers 7 is wrapped with a protective film 8, and the cotton fibers have good moisture absorption and air permeability. And the skin affinity is improved through the fluff layer.

[0025] The protective film 8 includes the following components in parts by weight: 20 parts of natural extracts, 10 parts of carbon nanotubes, 30 parts of dichloropentaflu...

Embodiment 2

[0036] The difference with Embodiment 1 is:

[0037] The protective film 8 includes the following components in parts by weight: 23 parts of natural extracts, 13 parts of carbon nanotubes, 35 parts of dichloropentafluoropropane, 30 parts of tridecafluorooctyltriethoxy silane.

[0038] The antibacterial agent comprises the following components in parts by weight: 7 parts of nano-titanium dioxide, 2 parts of Coptidis Rhizoma extract, 2 parts of Honeysuckle extract, 2 parts of Nepenthes extract, and 7 parts of Lavender extract.

[0039] The waterproof and breathable membrane 3 includes the following components in parts by weight: 30 parts of vinyl resin, 2 parts of hydrophobic silicon dioxide, 2 parts of hydrogen-containing polysiloxane, 2 parts of zirconium phosphate, 2 parts Zeolite, 6 parts of polyvinyl silicone oil, 11 parts of methyltrimethoxysilane.

Embodiment 3

[0041] The difference with Embodiment 1 is:

[0042] The protective film 8 includes the following components in parts by weight: 25 parts of natural extracts, 15 parts of carbon nanotubes, 40 parts of dichloropentafluoropropane, 40 parts of tridecafluorooctyltriethoxy silane.

[0043] The antibacterial agent comprises the following components in parts by weight: 10 parts of nano-titanium dioxide, 3 parts of Coptidis rhizome extract, 3 parts of honeysuckle extract, 3 parts of Nepenthes extract, and 10 parts of lavender extract.

[0044] The waterproof breathable membrane 3 includes the following components in parts by weight: 40 parts of vinyl resin, 3 parts of hydrophobic silicon dioxide, 5 parts of hydrogen-containing polysiloxane, 3 parts of zirconium phosphate, 3 parts Zeolite, 7 parts of polyvinyl silicone oil, 12 parts of methyltrimethoxysilane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com