A radiation-proof and heat-insulating coating

A radiation protection and coating technology, which is applied in the field of materials, can solve the problems of weakened coating radiation protection, poor radiation protection effect, and rising coating temperature, and achieve the effects of performance enhancement, electromagnetic shielding performance, and good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: the preparation of anti-radiation, heat-insulating coating

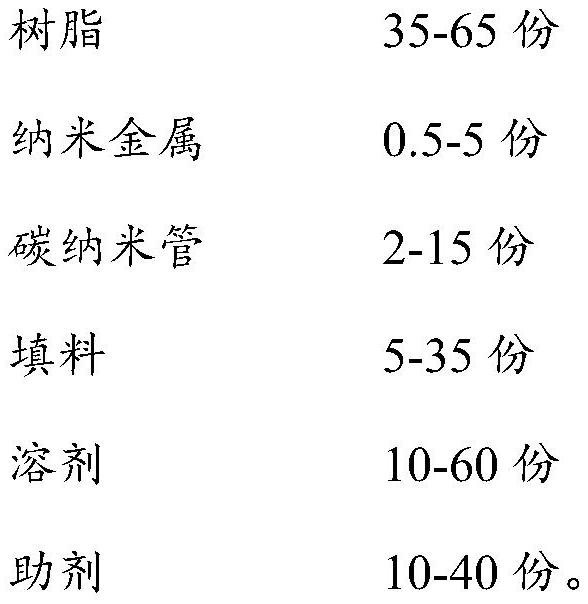

[0042] A radiation-proof, heat-insulating coating, comprising the following components by weight fraction:

[0043]

[0044] A preparation method for a radiation-proof, heat-insulating coating, comprising the following steps:

[0045] The components were weighed, stirred and mixed, the stirring speed was 800 rpm, the stirring time was 2 hours, and the stirring temperature was 50° C. to prepare a radiation-proof and heat-insulating coating.

Embodiment 2

[0046] Embodiment 2: the preparation of anti-radiation, heat-insulating coating

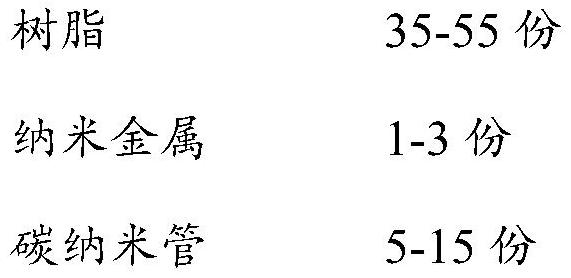

[0047] A radiation-proof, heat-insulating coating, comprising the following components by weight fraction:

[0048]

[0049] A preparation method for a radiation-proof, heat-insulating coating, comprising the following steps:

[0050] The components were weighed, stirred and mixed, the stirring speed was 900 rpm, the stirring time was 2 hours, and the stirring temperature was 40° C. to prepare a radiation-proof and heat-insulating coating.

Embodiment 3

[0051] Embodiment 3: the preparation of anti-radiation, heat-insulating coating

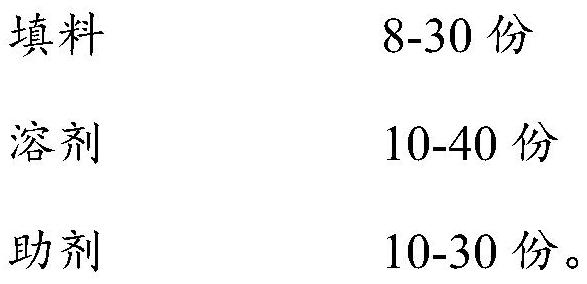

[0052] A radiation-proof, heat-insulating coating, comprising the following components by weight fraction:

[0053]

[0054] A preparation method for a radiation-proof, heat-insulating coating, comprising the following steps:

[0055] The components were weighed, stirred and mixed, the stirring speed was 1000 rpm, the stirring time was 1.5 hours, and the stirring temperature was 45° C. to prepare a radiation-proof and heat-insulating coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com