Closed hydraulic control system for travelling mechanism of construction vehicle

A technology of hydraulic control system and running mechanism, which is applied in the direction of fluid pressure actuation system components, mechanical equipment, fluid pressure actuation device, etc., and can solve the problems of difficult control of the synchronization of the running mechanism of engineering vehicles, differences in manufacturing accuracy, and anti-interference ability. Low power utilization rate and other issues, to achieve the effect of easy promotion and use, low operating cost and high power utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

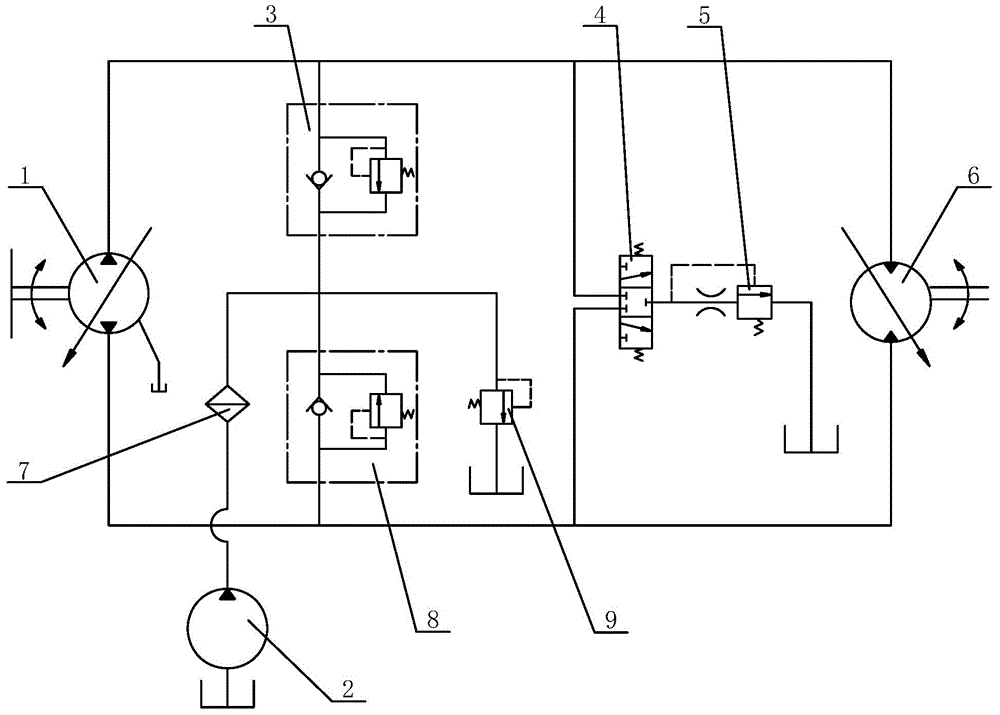

[0019] like figure 1 The closed hydraulic control system of the running gear of an engineering vehicle includes a hydraulic pump and a hydraulic motor, the hydraulic pump is a variable hydraulic pump 1, the hydraulic motor is a variable hydraulic motor 6, the variable hydraulic pump 1 and the hydraulic motor are The variable hydraulic motor 6 is connected in parallel, and the two outlets of the variable hydraulic pump 1 are connected in parallel with a one-way overflow valve 3 and a one-way overflow valve 2 8, which are oppositely arranged. The variable hydraulic pump 1 The two liquid outlets of the control valve 4 communicate with the first working oil port and the second working oil port respectively, and the third working oil port of the control valve 4 communicates with the inlet of the pilot relief valve 5, and the pilot relief valve 5 The outlet of overflow valve 5 is communicated with oil tank.

[0020] like figure 1 As shown, the pipeline between the first one-way re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com