Cabin ceiling lamp

A ceiling light and main body technology, applied in the field of ceiling lights, can solve the problems of high heat generation, end-of-life dark area, burning sensation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present embodiment will be further described below in conjunction with the accompanying drawings.

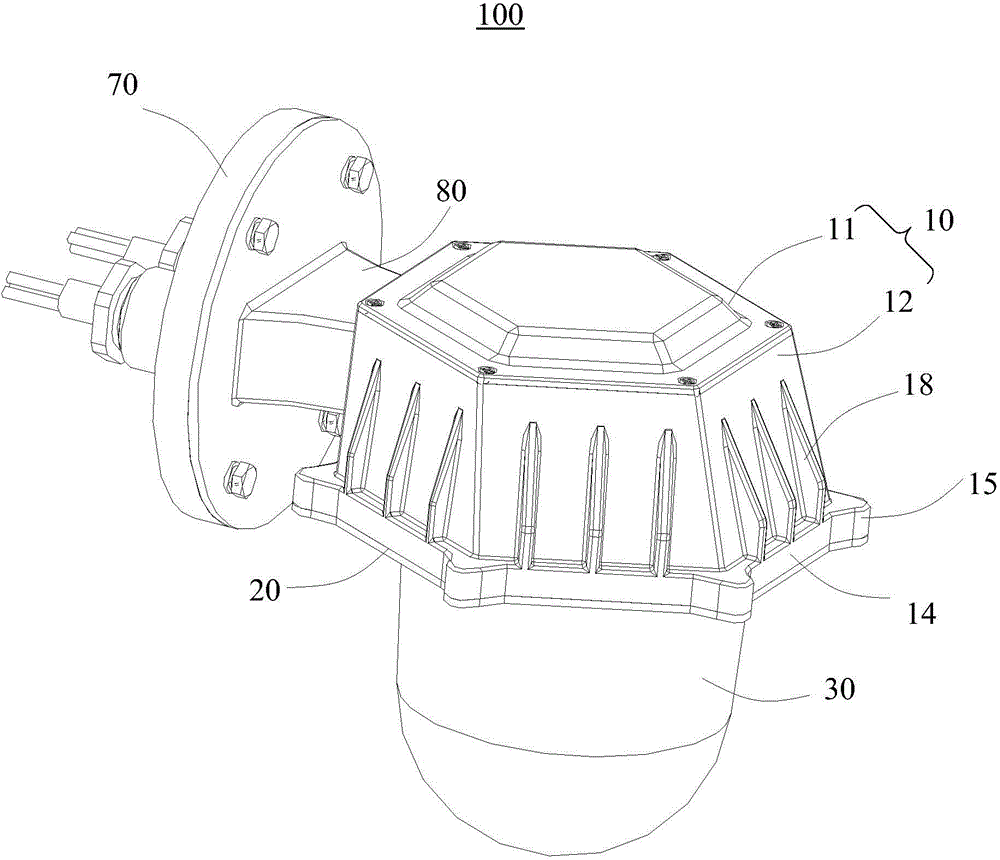

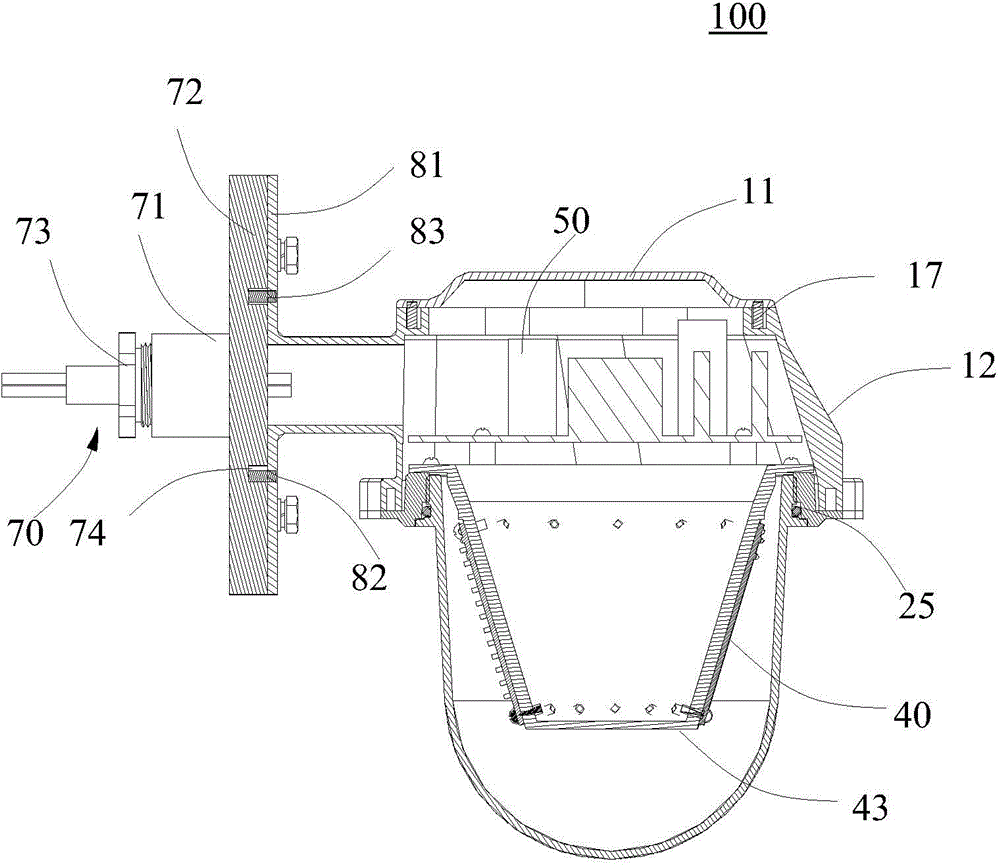

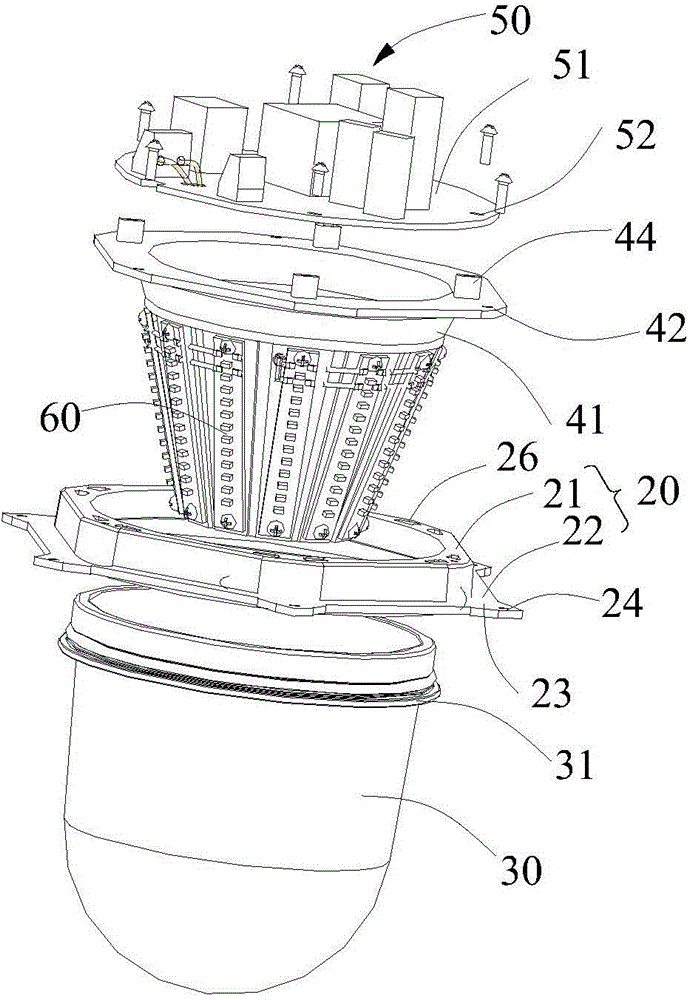

[0023] see figure 1 , a dome light 100 includes a housing 10 , a cover plate 20 , a transparent cover 30 , a driving board 50 , an LED light source 60 and a mounting bracket 70 .

[0024] The housing 10 is provided with a receiving portion and is generally in the shape of a hexagonal column with a trapezoidal cross section. In the illustrated embodiment, the housing 10 includes a main body 11 and an upper cover 12 , the main body 11 is a hollow structure in the shape of a truncated cone, and a convex edge 14 extends horizontally from the end surface of the main body 11 where the diameter is the largest. A plurality of lugs 15 extend horizontally from the convex edge 14 . The number of lugs 15 is six, which are evenly distributed on the outer periphery of the ledge 14 . In other embodiments, the ledges 15 may also be unevenly distributed on the outer periphery of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com