Variable temperature sample platform and thermoelectric property measuring method

A technology of thermoelectric performance and sample stage, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., it can solve the problems of inability to measure thermoelectric potential, and the average temperature of the sample cannot be accurately maintained at a certain set value. The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

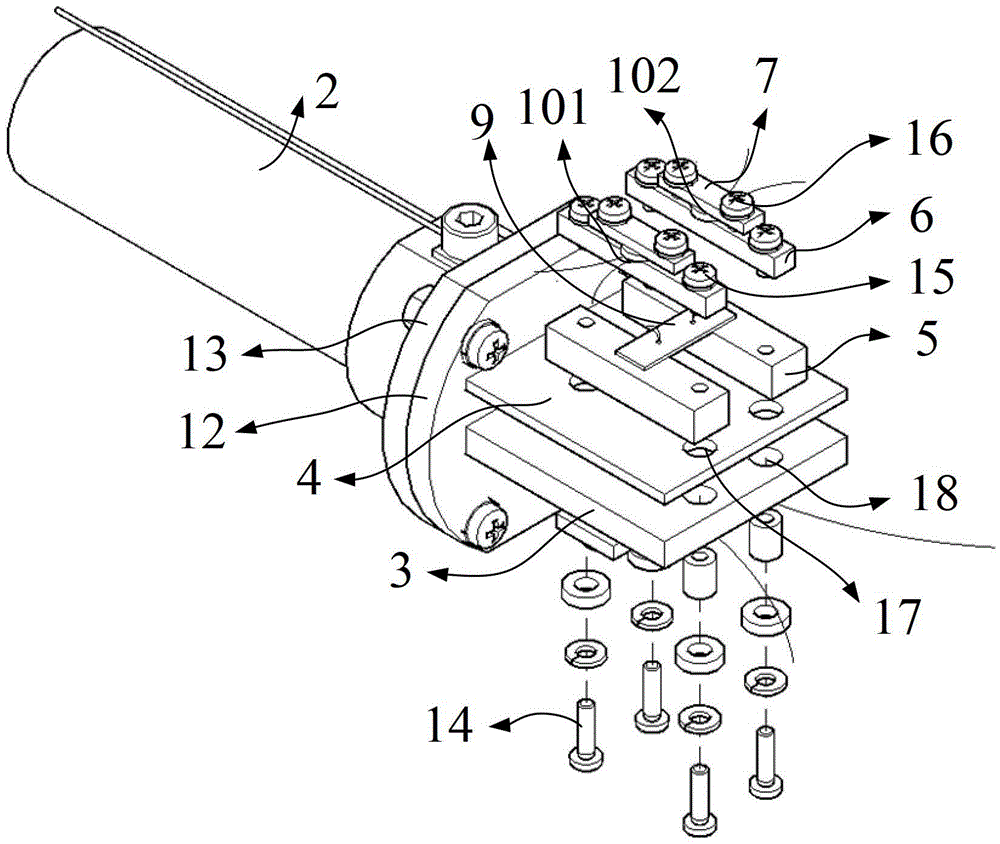

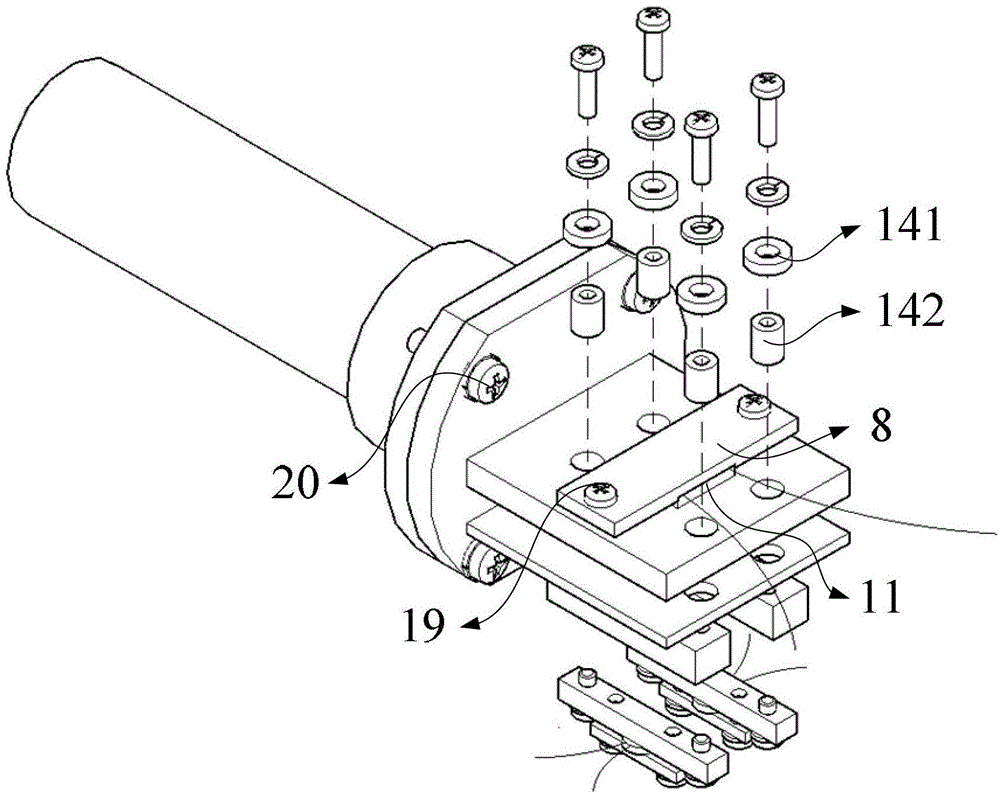

[0073] figure 1 and figure 2 Shown are the schematic diagrams of the upper structure and the lower structure of the variable temperature sample stage provided in this embodiment, respectively.

[0074] A temperature-variable sample stage provided in this embodiment includes a sample holder, a sample rod 2 , and a connecting piece arranged between the sample holder and the sample rod 2 .

[0075] The sample holder includes a base 3 , an insulating backing plate 4 and a sample spacer 5 . There are two sample cushion blocks 5, and the two sample cushion blocks 5 are arranged in parallel with a certain interval in the middle, and are symmetrically distributed, and each of the sample cushion blocks 5 is connected to the two first fasteners 14 through two first fasteners 14. The base 3 is fixedly connected.

[0076] The insulating backing plate 4 is located between the sample block 5 and the base 3, the insulating backing plate 4 is provided with four first through holes 17, and...

Embodiment 2

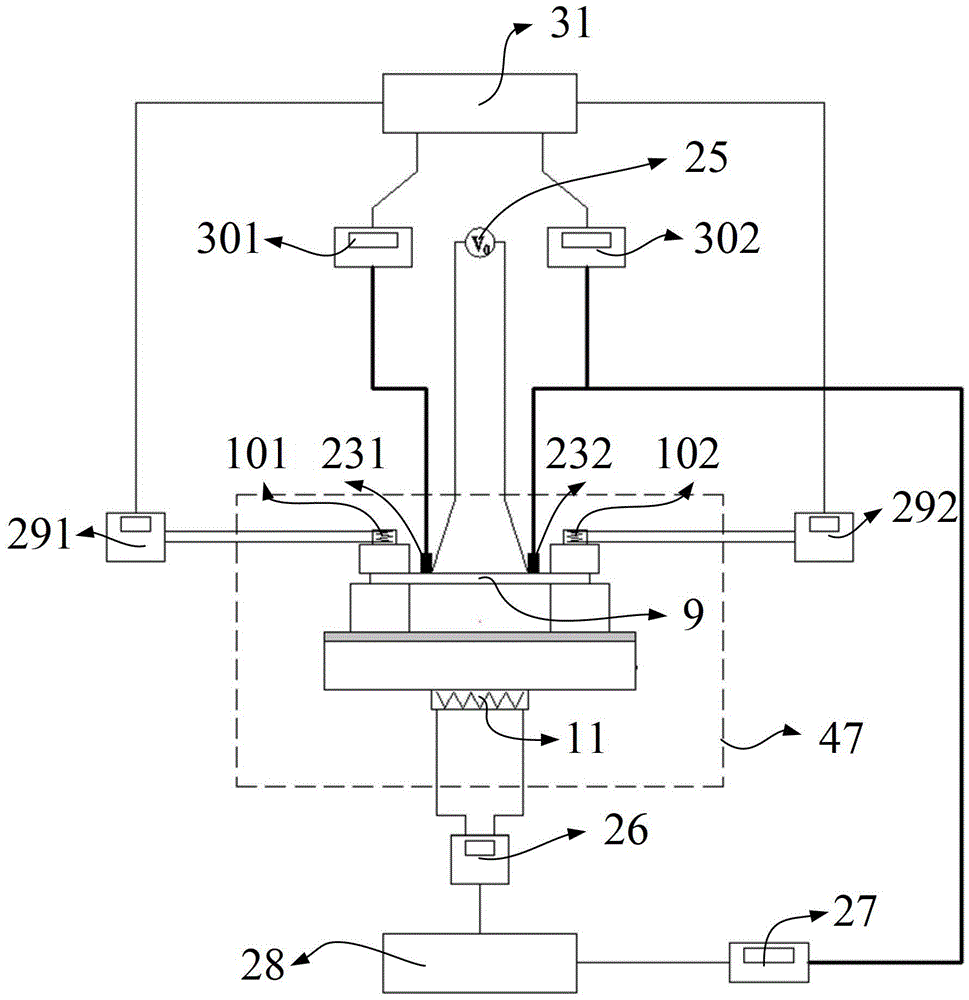

[0085] Such as Figure 10 Shown is a schematic structural diagram of the dual-mode pyroelectric performance detection device provided in this embodiment.

[0086] A dual-mode thermoelectric performance measurement device provided in this embodiment is equipped with a variable temperature sample stage, including a variable temperature sample stage, a voltage measuring instrument, a current source meter, a temperature measuring instrument, vacuum equipment, liquid nitrogen filling equipment, a computer 43, PID controller and resistance measuring instrument, etc.

[0087] The vacuum equipment includes a vacuum chamber 47 , a vacuum acquisition device connected to the vacuum chamber 47 and a vacuum measuring device for detecting the vacuum degree of the vacuum chamber 47 . The vacuum obtaining device includes a molecular pump 50 and a mechanical pump 51 connected to the molecular pump 50 . The vacuum measuring device includes a vacuum gauge 52 arranged on the vacuum chamber 47 a...

Embodiment 3

[0109] A thermoelectric performance measurement method of a dual-mode thermoelectric performance measurement device equipped with a variable temperature sample stage is implemented according to the following steps:

[0110] Step S0: fixing the sample strip 9 on the variable temperature sample stage.

[0111] Step S1: placing the variable temperature sample stage in the vacuum chamber 47 of the dual-mode thermoelectric property measurement device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com