LED lamp

A technology of LED lamps and lamps, which is applied to the cooling/heating devices of lighting devices, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., which can solve problems such as poor air flow, limited angle adjustment of LED lamps, and single functions. The effect of simple structure, rapid heat dissipation and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

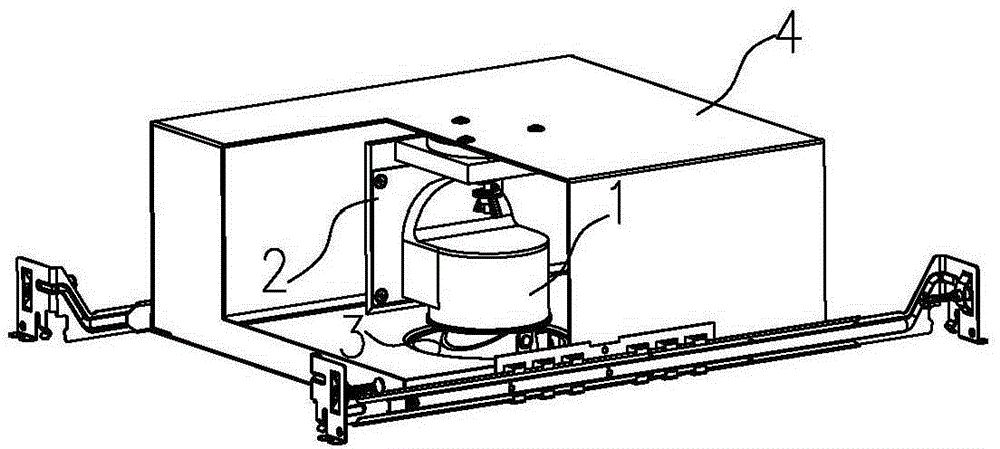

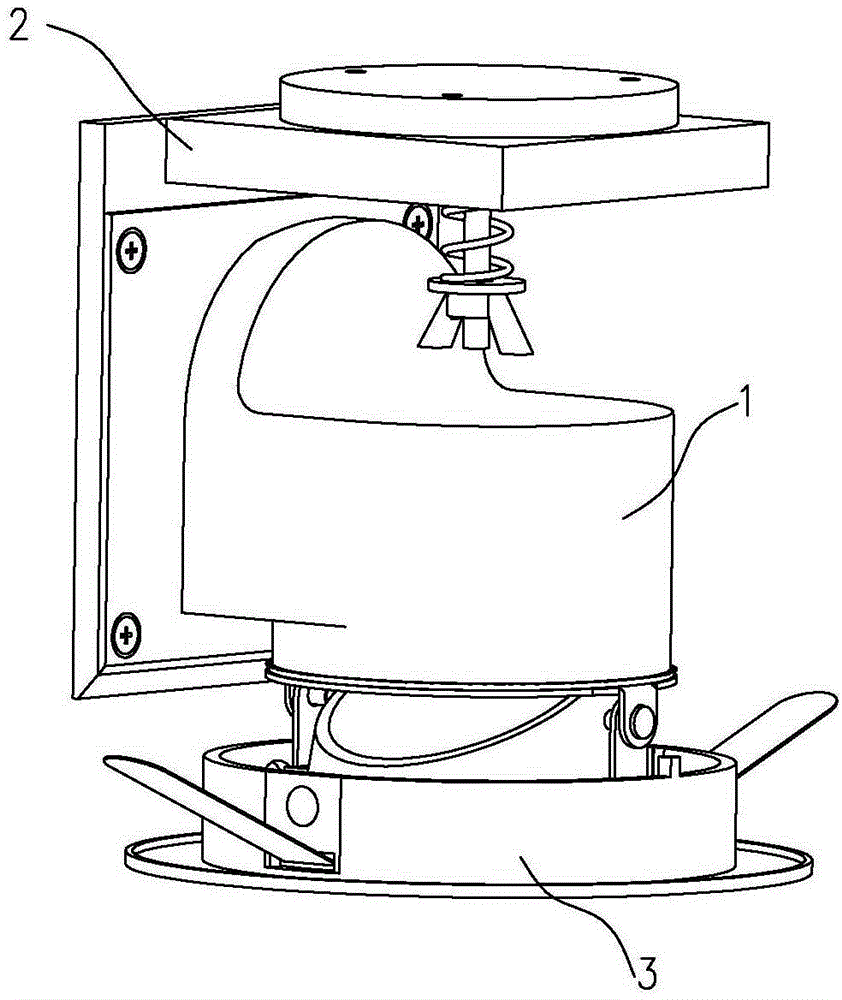

[0035] One of the specific implementation modes of an LED lamp created by the present invention, such as figure 1 As shown, it includes a light source assembly 1, a heat transfer assembly 2, a panel assembly 3 and a lamp housing 4, and the light source assembly 1, heat transfer assembly 2 and panel assembly 3 form a lamp body assembly, such as figure 2 As shown, the lamp body assembly is fixedly connected to the lamp housing 4 through a heat transfer assembly.

[0036] The lamp housing 4 is a polygonal box body, preferably a square box body. The bottom of the lamp housing 4 has a circular light opening. The lamp body assembly is installed in the lamp housing 4 and emits light through the light opening.

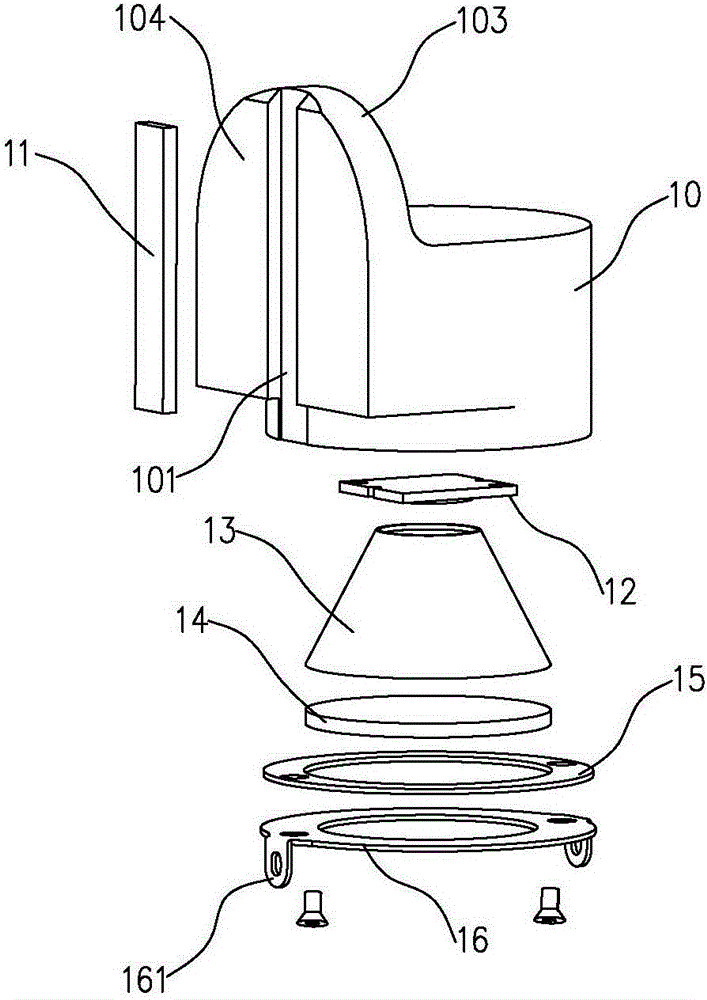

[0037] The heat transfer component 2 is fixedly connected to the lamp housing 4, and the heat transfer component 2, such as Figure 4 As shown, it includes iron heat conduction sheet 20 , heat conduction plate 21 and connecting device, and the connecting device includes heat...

Embodiment 2

[0042] The second specific embodiment of an LED lamp created by the present invention includes a light source assembly 1, a heat transfer assembly 2 and a lamp housing 4, the light source assembly 1 and the heat transfer assembly 2 form a lamp body assembly, and the lamp body assembly is fixed by the heat transfer assembly Connected to the lamp shell 4.

[0043] The lamp housing 4 is a polygonal box body, preferably a square box body. There is a circular light opening at the bottom of the lamp housing. The lamp body assembly is installed in the lamp housing 4 and emits light through the light opening.

[0044] The heat transfer assembly 2 is fixedly connected to the lamp housing 4 , and the heat transfer assembly 2 includes a heat conduction plate 21 . A heat-conducting horizontal plate 27 is fixedly connected to the upper part of the heat-conducting plate 21, and the heat-conducting horizontal plate 27 is fixedly connected with the lamp housing 4 by screws. The heat-conductin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com