Method for actively killing injurious insects in grain bulk by using gas-solid two-phase flow

A gas-solid, grain pile technology, applied in the application, edible seed preservation, and chemical preservation of seeds, etc., can solve the high requirements of temperature and relative humidity granary airtightness, easy to be affected by pest species, and insecticidal effect. It is not obvious and other problems, and achieves the effects of preventing mildew and grain agglomeration, good insect control and insecticidal effect, and low labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

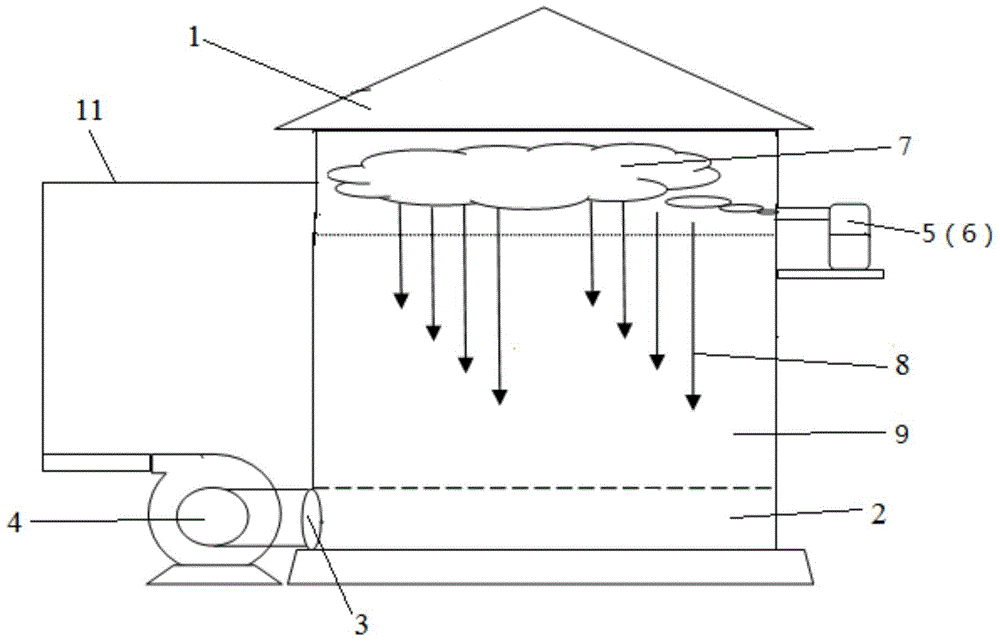

[0056] The Method of Actively Killing Insects by Two-Phase Flow Downward Spraying

[0057] Such as figure 1As shown in , the system includes: a granary 1, an air duct 2, a ventilator 4 and a duster 5 (such as a spray duster). Grain pile 9 is placed in granary 1. The ventilation channel 2 is located below the bottom surface of the granary 1 . The air inlet of the ventilator 4 is connected with the air duct opening 3 . The duster 5 communicates with the granary 1 at a position higher than the upper surface of the grain pile.

[0058] Start ventilator 4, form downward vertical airflow in bulk grain grain pile 9. Powder 6 (food anticaking agent silicon dioxide) is sprayed to the upper space of bulk grain grain pile 9 with the duster 5 that powder 6 is installed, and the gas-solid two-phase aerosol 7 that forms gas and solid mixture. The gas-solid two-phase aerosol 7 will form a gas-solid two-phase flow 8 along with the vertical airflow of the ventilator, and enter the grain p...

Embodiment 2

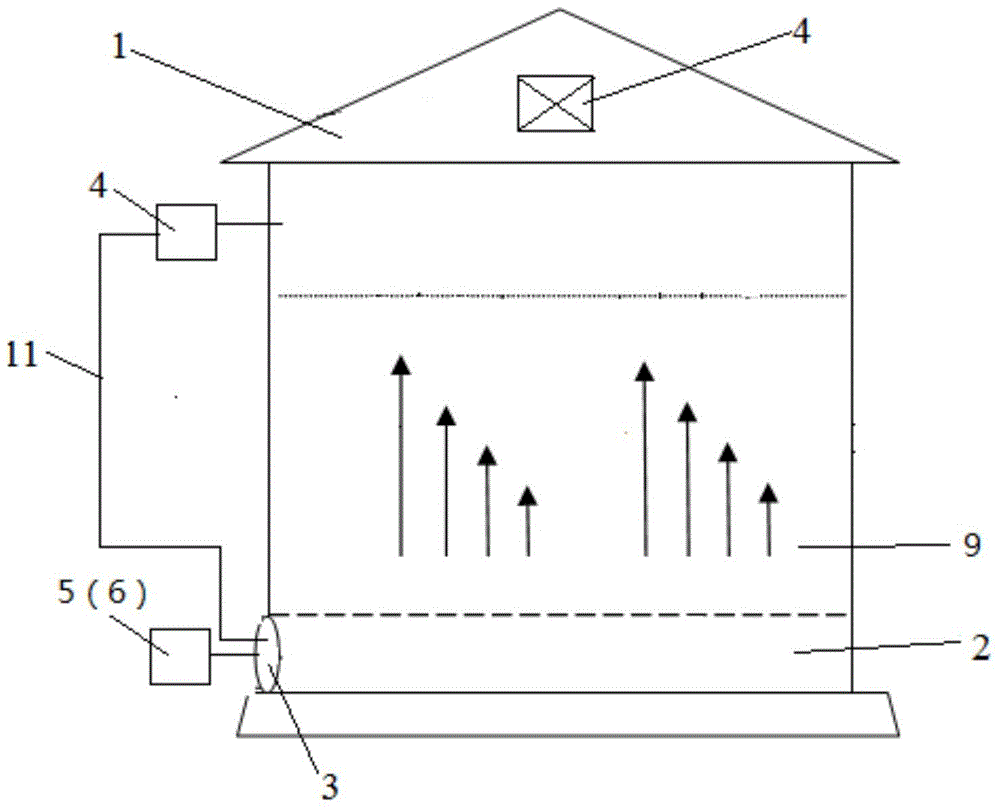

[0063] The Method of Actively Killing Insects by Two-Phase Flow Upward Pollination

[0064] Such as figure 2 As shown in , the system includes: a granary 1, an air duct 2, a ventilator 4 and a duster 5. Grain pile 9 is placed in granary 1. The ventilation duct 2 is arranged below the bottom surface of the granary 1 . The ventilator 4 is arranged outside the granary, and the air inlet communicates with the granary 1 at a position higher than the upper surface of the grain pile. The powder sprayer 5 is arranged outside the granary, and the powder outlet is connected with the ventilation channel mouth 3 .

[0065] Open the duster 5, spray powder 6 (food anti-caking agent silicon dioxide), the powder 6 is mixed with the air in the ventilation channel to form a gas-solid two-phase aerosol (not shown); The tuyeres generate an upward airflow in the granary 1, and the upward airflow drives the gas-solid two-phase aerosol into the granary 1 through the ventilation opening 3, formi...

Embodiment 3

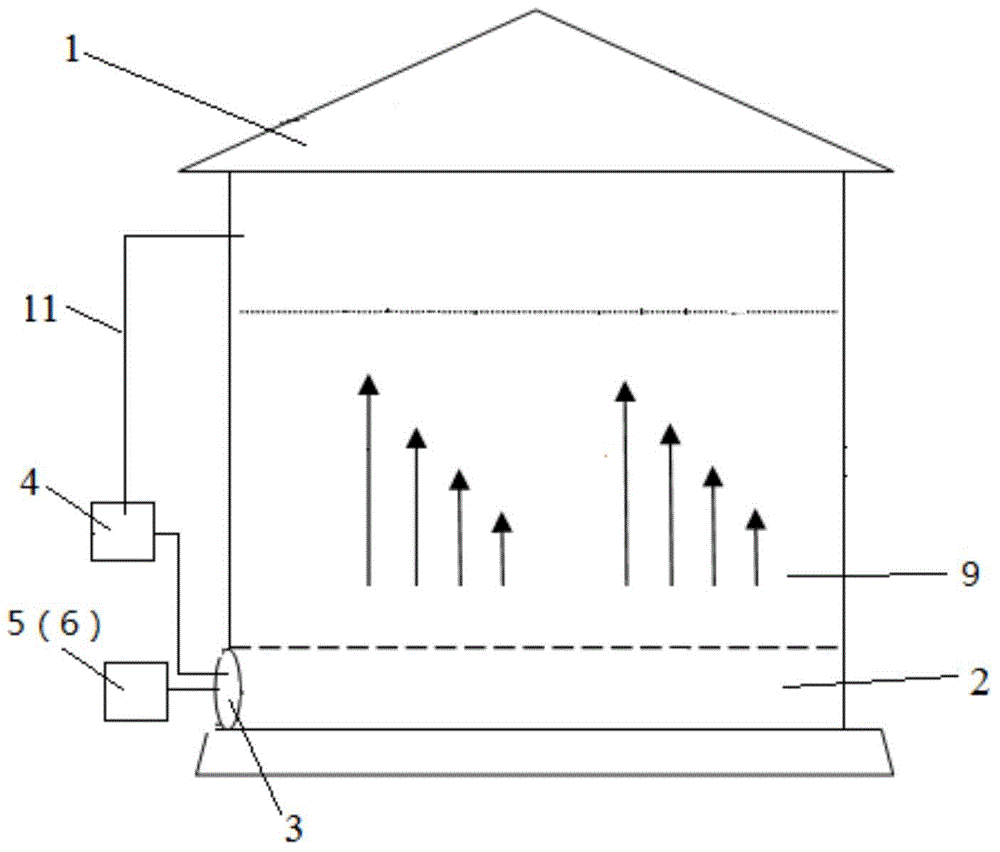

[0077] The Method of Actively Killing Insects by Fan Press-in Two-Phase Flow Upward Spraying Powder

[0078] Such as image 3 As shown in , the system includes: a granary 1, an air duct 2, a ventilator 4 and a duster 5. Grain pile 9 is placed in granary 1. The ventilation duct 2 is arranged below the bottom surface of the granary 1 . Ventilator 4 is arranged outside the granary, and the air outlet links to each other with ventilation channel mouth 3. The powder sprayer 5 is arranged outside the granary, and the powder outlet is connected with the ventilation channel mouth 3 .

[0079] Open the powder sprayer 5, spray powder 6 (food anti-caking agent silicon dioxide), the powder 6 is mixed with the air in the ventilation channel to form a gas-solid two-phase aerosol (not shown); open the fan 4, the fan 4 The air outlet generates upward airflow in the granary 1 through the air duct 3, and the upward airflow drives the gas-solid two-phase aerosol into the granary 1 to form a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com