Method for prevention of formation of abnormal flavor in raw milk or pasteurized milk, and pasteurized milk processed by the method

A technology for sterilized milk and raw milk, applied in the field of sterilized milk, can solve problems such as unrecorded quality or flavor of raw milk, and achieve the effects of promoting purchase desire, effective utilization without waste, and stable supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

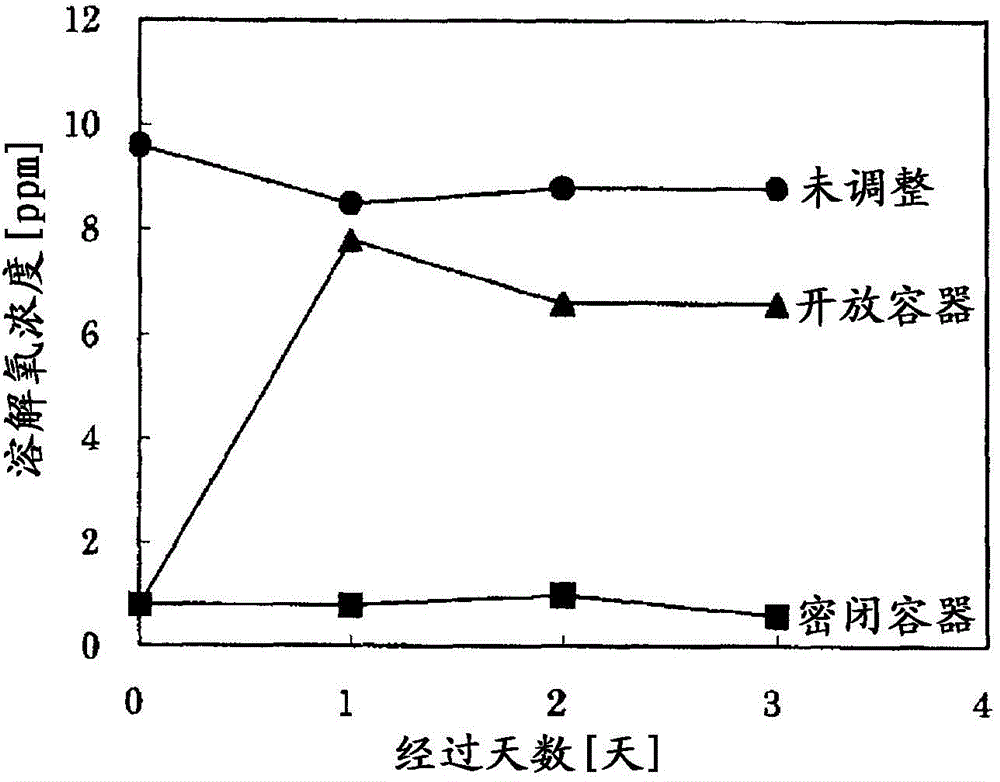

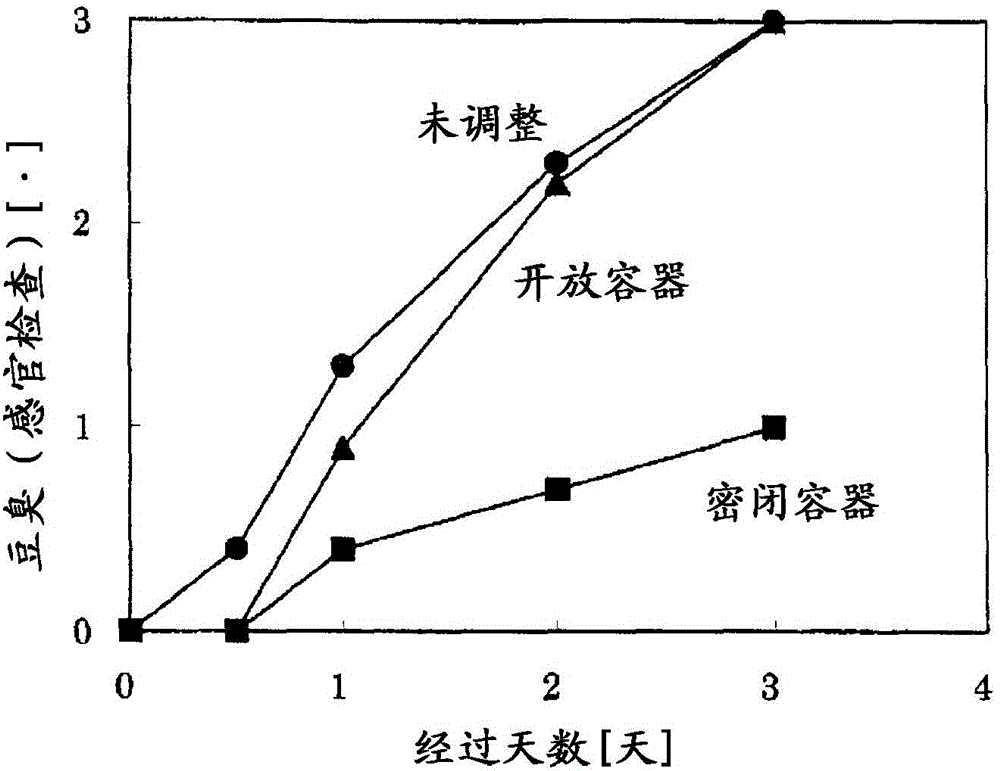

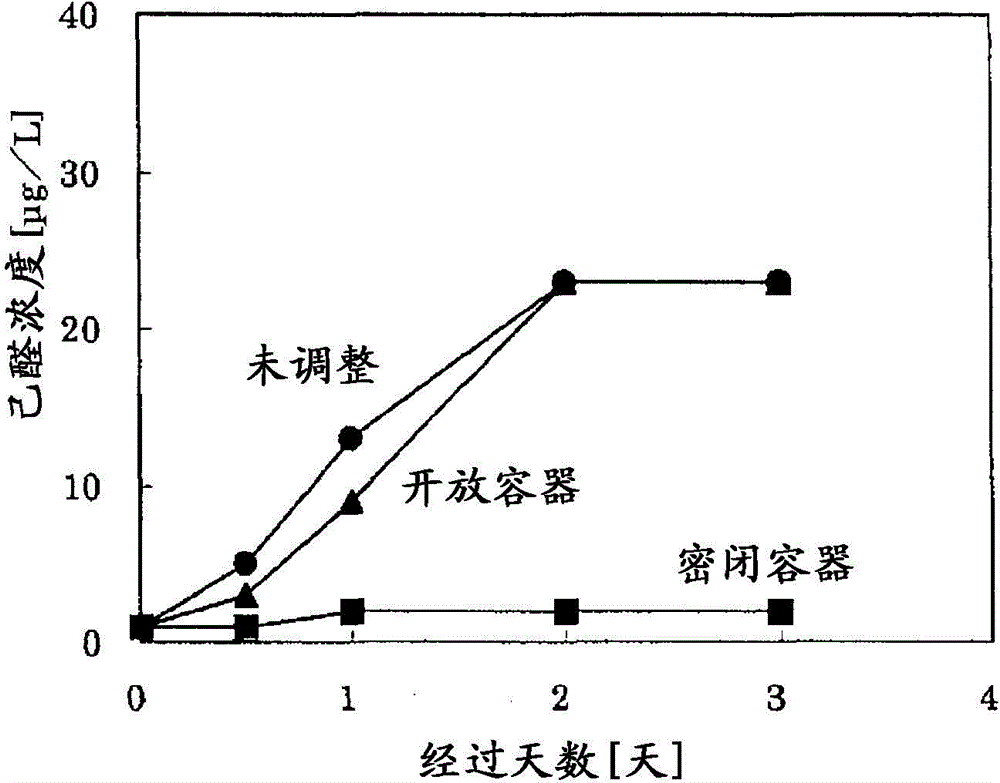

[0119] (Changes in concentration of bean odor and hexanal over time when the concentration of dissolved oxygen is reduced immediately after milking, when kept in an open container and when kept in a closed container)

[0120] Immediately after milking, the concentration of dissolved oxygen was lowered, and the time-dependent changes in the concentration of soybean odor and hexanal were investigated when the milk was kept in an open container and when it was kept in a closed container.

[0121] About 30 minutes after milking, cool the raw milk to 8°C. The dissolved oxygen concentration of raw milk at this time was 9.6 ppm (temperature 8 degreeC). This raw milk whose dissolved oxygen concentration was not adjusted was referred to as "unadjusted raw material milk" and a control sample (control).

[0122] Immediately after milking, nitrogen was passed through the unadjusted raw milk to reduce the dissolved oxygen concentration to 0.8ppm (at a temperature of 7°C).

[0123] Two ty...

Embodiment 2

[0154] (Changes in hexanal concentration over time when dissolved oxygen concentration decreases immediately after milking, 24 hours after milking, and 48 hours after milking)

[0155] The temporal change of the hexanal concentration when the dissolved oxygen concentration decreased immediately after milking, 24 hours after milking, and 48 hours after milking was investigated.

[0156] About 30 minutes after milking, cool the raw milk to 8°C. The dissolved oxygen concentration of raw milk at this time was 9.6 ppm (temperature 8 degreeC). This raw milk whose dissolved oxygen concentration was not adjusted was referred to as "unadjusted raw material milk" and a control sample (control).

[0157] As for the time after milking to lower the dissolved oxygen concentration, three different elapsed times were set: immediately after milking, 24 hours after milking, and 48 hours.

[0158] Immediately after milking, after 24 hours from the start of milking, and after 48 hours, pass nit...

Embodiment 3

[0175] (The hexanal concentration changes over time when the dissolved oxygen concentration of raw milk that is prone to spontaneous oxidation is changed by replacing oxygen with an inert gas)

[0176] The temporal change of the hexanal concentration was investigated when the dissolved oxygen concentration was changed immediately after milking raw material milk which is prone to spontaneous oxidation.

[0177] As a method of reducing the concentration of dissolved oxygen, a method of replacing oxygen with an inert gas can be used.

[0178] About 30 minutes after milking, the temperature of raw milk is cooled to 8°C. The dissolved oxygen concentration of raw milk at this time was 9.6 ppm (temperature 8 degreeC).

[0179] This raw milk whose dissolved oxygen concentration was not adjusted was referred to as "unadjusted raw material milk" and a control sample (control).

[0180] The dissolved oxygen concentration after milking was set at two levels of 0.8ppm and 4.8ppm (at a te...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap