Cigarette filter tip reducing carbonyl compounds in cigarette mainstream smoke and manufacture method thereof

A technology for mainstream cigarette smoke and aldehyde compounds, which is applied in e-liquid filter, tobacco, food science and other directions, can solve the problems of complex processing technology and negative impact on the smoking quality of cigarettes, and achieves a simple preparation method and changed adsorption performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

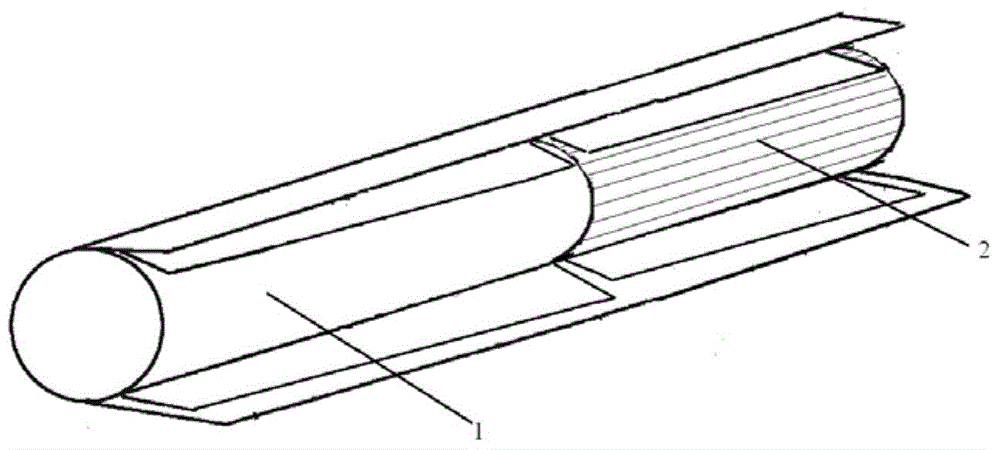

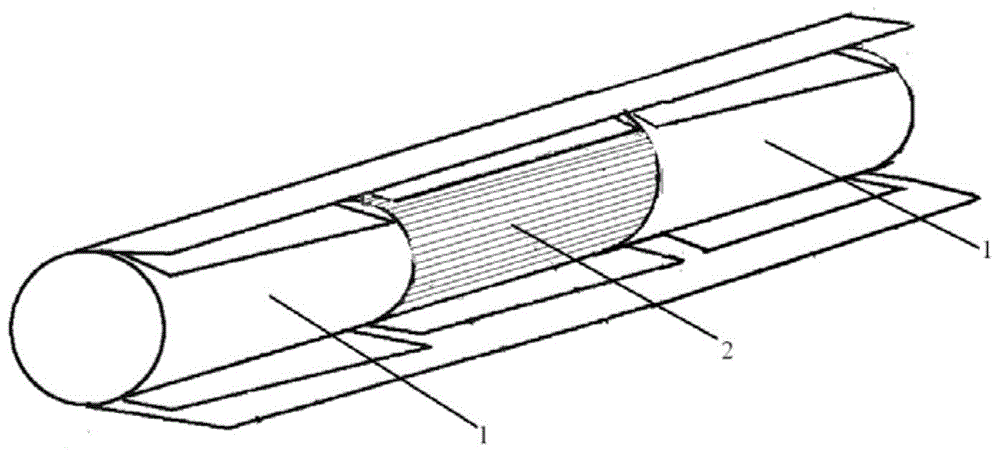

[0025] Disperse 10g of amino-functionalized multi-walled carbon nanotubes evenly in water, then slowly add 3g of chitosan to it, ultrasonically disperse it for 5 minutes, transfer it to a watering can with pressure, and evenly spray it on the surface of 87g shredded tobacco. The shredded tobacco was dried at 60° C. for 6 hours to obtain the shredded tobacco of the corresponding carbonaceous material. Then roll the shredded tobacco into a cigarette filter base rod, and compound it with the cellulose acetate base rod at a ratio of 10:15 to form a cigarette filter rod. The tobacco material part is placed in the shredded tobacco section, and the length is 10 mm.

Embodiment 2

[0027] Disperse 10g of amino-functionalized multi-walled carbon nanotubes evenly in water, then slowly add 3g of xanthan gum to it, ultrasonically disperse it for 5 minutes, transfer it to a watering can with pressure, and evenly spray it on the surface of 85g of expanded tobacco stems, The treated expanded shredded tobacco stems were dried at 80° C. for 3 hours to obtain the corresponding expanded shredded tobacco stems of carbonaceous material. Then the expanded shredded tobacco stem is rolled into a cigarette filter rod base rod, which is compounded with the acetate fiber base rod at a ratio of 10:15 to form a cigarette filter rod, and the tobacco material part is placed in the shredded tobacco section with a length of 10 mm.

Embodiment 3

[0029] Disperse 15g of multi-walled carbon nanotubes evenly in water, then slowly add 5g of guar gum to it, ultrasonically disperse for 10 minutes, transfer to a watering can with pressure, spray evenly on the surface of 80g of shredded tobacco stems, and put the processed The shredded tobacco stems were dried at 80° C. for 3 hours to obtain shredded tobacco stems of corresponding carbonaceous materials. Then the shredded tobacco stem is rolled into a cigarette filter rod base rod, which is composited with the acetate fiber base rod at a ratio of 10:15 to form a cigarette filter rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com