A kind of environment-friendly flame-retardant ABS composite material and preparation method thereof

A composite material and ABS resin technology, which is applied in the field of environmentally friendly flame-retardant ABS composite materials and their preparation, can solve problems such as poor compatibility, affecting product application and appearance of parts, delamination and peeling, and achieve good industrial application value , Solve processing and application defects, improve toughness and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

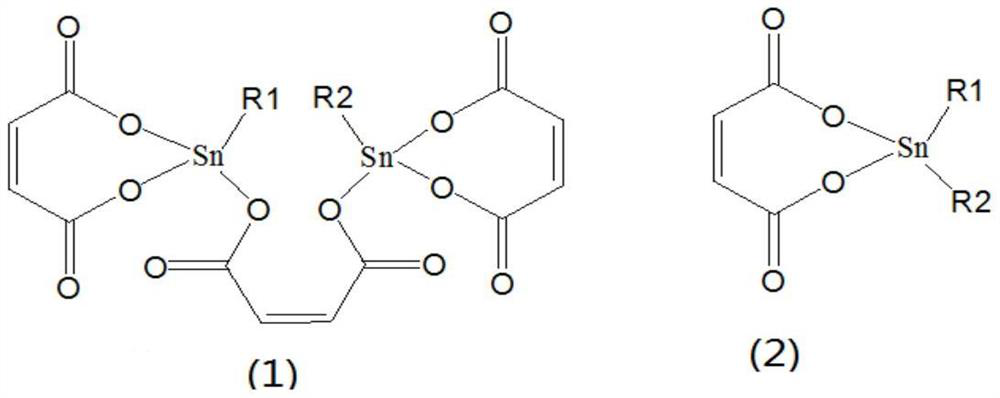

Image

Examples

Embodiment Construction

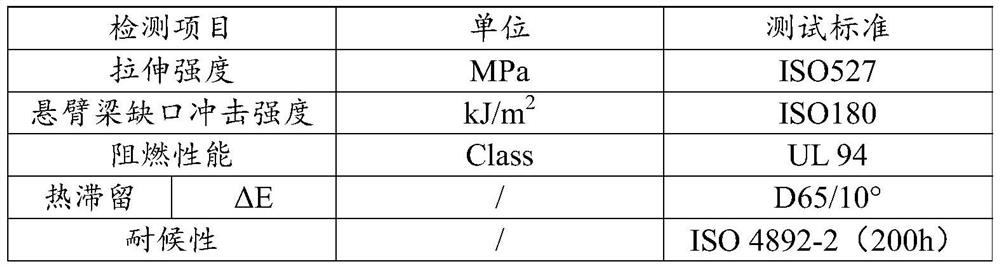

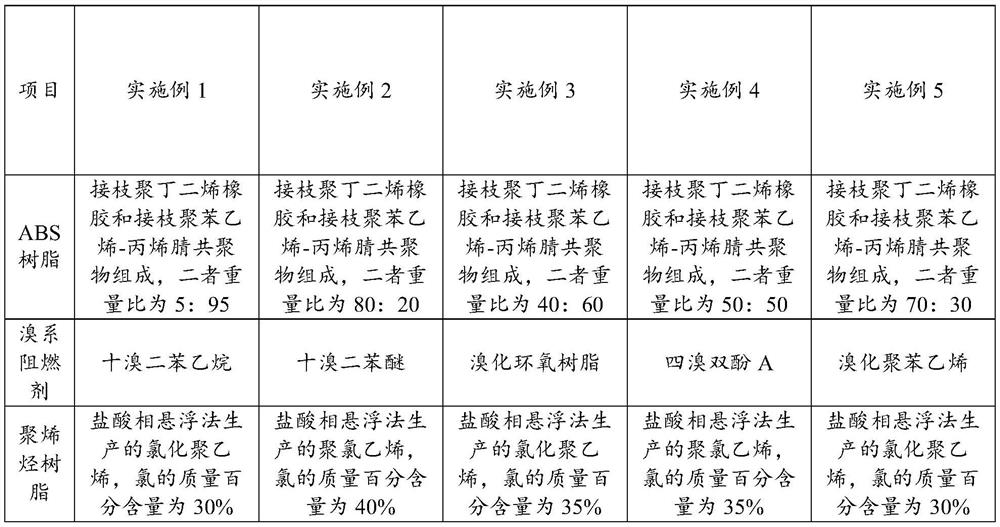

[0024] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with specific examples.

[0025] The preparation method of ABS composite material in the embodiment of the present invention is:

[0026] (1) Mix ABS resin, polyolefin resin, brominated flame retardant, antimony flame retardant, compatibilizer and processing aid in a high-speed mixing mixer or enter the twin-screw extruder separately through a metering feeder out of the machine;

[0027] (2) Under the conveying, mixing and shearing action of the twin-screw extruder, the ingredients in the formula are fully melted and plasticized, kneaded and mixed, extruded through the machine head, drawn, cooled, pelletized, dried and packaged, Obtain the new environment-friendly flame-retardant ABS composite material; wherein, the screw temperature of each section of the twin-screw extruder from the feeding port t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com