Machine for removing wrinkles of vamp by using steam

A steam and upper surface technology, applied in the field of mechanical processing, can solve the problems of increasing the difficulty of processing, easy drop of leather shoes, economic loss, etc., and achieve the effects of improving use efficiency, fast wrinkle removal process, and reducing loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

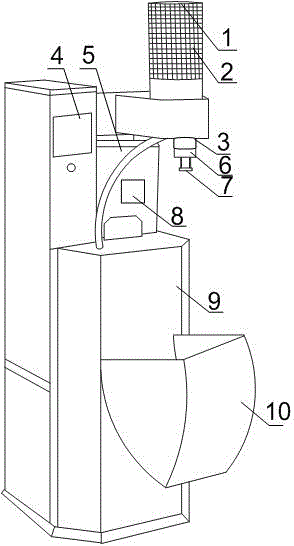

[0021] Such as figure 1 As shown, the present embodiment comprises frame 9, fan and water tank 5, and described fan and water tank 5 are all arranged on the frame 9, and the top of described fan is provided with air inlet 1, and the bottom of fan is provided with air outlet 6 and Pressure roller 7, the pressure roller 7 is placed directly below the air outlet 6, and also includes a support frame 10 fixed on the frame 9, the frame opening of the support frame 10 is directly below the pressure roller 7, and the air outlet 6 is also A wind pressure switch is provided, a water level alarm 8 is provided in the water tank 5, and a digital display thermostat 4 arranged on the frame 9 is also included. The air entering through the air inlet 1 and the water in the water tank 5 are mixed with the heated air and water vapor after the heat treatment of the heating wire; the mixed gas is sent to the air outlet 6 under the action of the fan. The leather to be wrinkled is placed under the p...

Embodiment 2

[0026] Such as figure 1 As shown, in this embodiment, on the basis of Embodiment 1, the water level alarm 8 includes a wireless water level sensor, a wireless sound and light alarm and a power supply, and the power supply is connected to the wireless water level sensor and the wireless sound and light alarm respectively. The wireless transmitting end of the wireless water level sensor is connected with the wireless receiving end of the wireless sound and light alarm. When it is detected that the water level in the water tank 5 is lower than the minimum alarm value, the wireless transmitter immediately transmits the alarm signal wireless password to the wireless audible and visual alarm, and the audible and visual alarm immediately sounds the whistle after receiving the signal, prompting the operator to correct the alarm. Water tank 5 carries out adding water processing.

Embodiment 3

[0028] Such as figure 1 As shown, on the basis of Embodiment 1 and Embodiment 2, this embodiment also includes an air filter 2 disposed in the air inlet 6 and a support frame 10 disposed below the air outlet 6 . When the processed leather surface accidentally falls, the support frame 10 provided below the pressure roller 7 collects it, avoiding the damage caused by the leather surface landing on the ground; when the air is heated, the air filter 2 can filter the air, so that The heated air will not produce carbon deposits, preventing black spots on the leather upper surface during the ironing and wrinkle removal process of the light-colored leather upper.

[0029] Preferably, the fan is a medium-pressure vortex fan. The medium-pressure traveling vortex blower outputs strong wind power, drives high-temperature steam to spray on the leather surface, and uses the pressure roller 7 to roll repeatedly to quickly eliminate wrinkles on the leather surface.

[0030] Preferably, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com