Vamp wrinkle removing mechanism

A fan and frame technology, applied in the field of upper surface wrinkle removal mechanism, can solve the problems of low efficiency of wrinkle removal, increased processing difficulty, easy scald leather, etc., to avoid dry heating of heating wire, improve use efficiency, and prevent black spot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

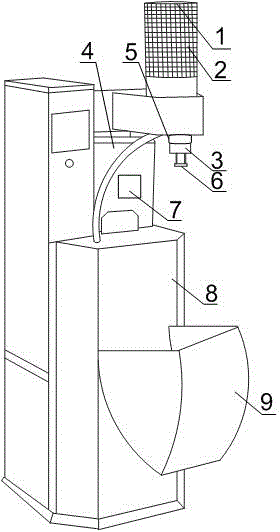

[0019] Such as figure 1 As shown, the present embodiment comprises frame 8, fan and water tank 4, and described fan and water tank 4 are all arranged on the frame 8, and the top of described fan is provided with air inlet 1, and the bottom of fan is provided with air outlet 3 and Pressure roller 6, the pressure roller 6 is placed directly below the air outlet 3, and also includes a collection frame 9 fixed on the frame 8, the frame opening of the collection frame 9 is directly below the pressure roller 6, and the air outlet 3 is also A wind pressure switch 5 is provided. The air entering through the air inlet 1 and the water in the water tank 4 are heated by the heating wire, and the heated air and water vapor are mixed; the mixed gas is sent to the air outlet 3 under the action of the fan. The leather to be wrinkled is placed under the pressure roller 6 at the air outlet 3, and the mixed gas and the pressure roller 6 are used together to quickly smooth the wrinkled leather s...

Embodiment 2

[0022] Such as figure 1 As shown, on the basis of Embodiment 1, this embodiment also includes a water level alarm 7 arranged in the water tank 4 . Due to the high requirements of the wrinkle removal process, more time is spent on processing, and the demand for water in the water tank 4 is relatively large. When the water level in the water tank 4 is low, the water level alarm 7 arranged in the water tank 4 will process it according to the height of the water level, and the alarm will send out a prompt alarm in time, and the operator will replenish the water in time, avoiding the accident caused by the lack of water. If the heating wire is dry-burned, it is helpful to maintain the equipment and improve the efficiency of the equipment.

Embodiment 3

[0024] Such as figure 1 As shown, in this embodiment, on the basis of Embodiment 1, the water level alarm 7 includes a wireless water level sensor, a wireless sound and light alarm and a power supply, and the power supply is connected to the wireless water level sensor and the wireless sound and light alarm respectively. The wireless transmitting end of the wireless water level sensor is connected with the wireless receiving end of the wireless sound and light alarm. When it is detected that the water level in the water tank 4 is lower than the minimum alarm value, the wireless transmitting terminal immediately transmits the alarm signal wireless password to the wireless audible and visual alarm, and the audible and visual alarm immediately sounds the whistle after receiving the signal, prompting the operator to correct the alarm. Water tank 4 carries out adding water treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com